A device and method for simulating the formation of cracks in initially solidified slabs in continuous casting crystallizers

A continuous casting crystallizer and simulation device technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems that it is impossible to propose targeted preventive measures, it is difficult to study the crack mechanism of the solidified slab shell, and the cracks cannot be simulated. Accurate and controllable temperature, low experiment cost and convenient experiment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

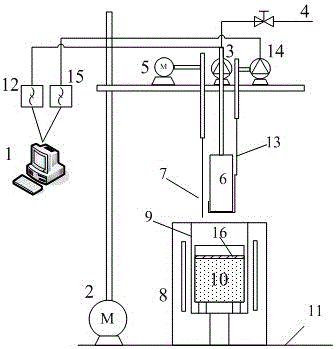

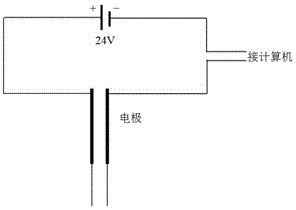

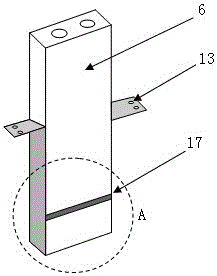

[0020] Such as Figure 1 ~ Figure 4 As shown, an embodiment of the present invention includes a base 11 on which an induction furnace 8, a liquid level positioning bracket 5, a crystallizer copper mold movement system bracket 2, a vibration system motor 3, and a drawing motor 14 are fixed. There is a crucible 9 for holding molten steel 10 and continuous casting mold mold slag 16; above the induction furnace 8, there are liquid level positioning electrodes 7, billet drawing device 13 and mold copper mold 6, and the liquid level positioning electrodes 7 are fixed On the liquid level positioning bracket that can move vertically under the drive of the liquid level positioning motor 5; the crystallizer copper mold 6 is fixed on the crystallizer that can move vertically under the drive of the mold copper mold movement system motor On the support 2 of the copper mold movement system, the vibration system motor 3 can drive the crystallizer copper mold 6 to vibrate according to the set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com