Dynamic flexible job-shop scheduling method based on multi-objective evolutionary algorithm

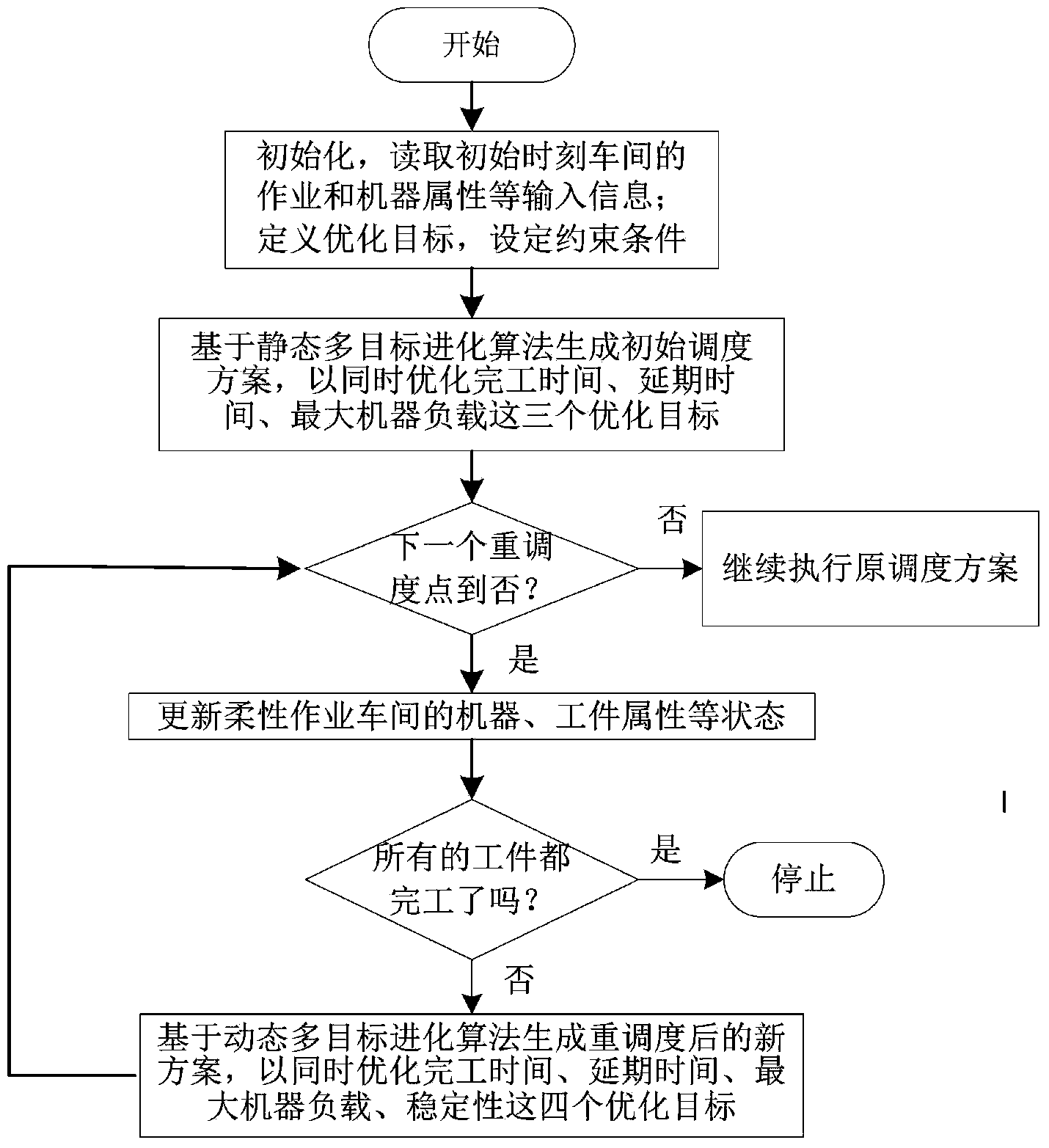

A multi-objective evolution and flexible operation technology, applied in the field of flexible job shop scheduling control, can solve the problems that the scheduling scheme is no longer applicable, and the processing method of multiple optimization objectives is single, so as to achieve the effect of optimizing the completion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

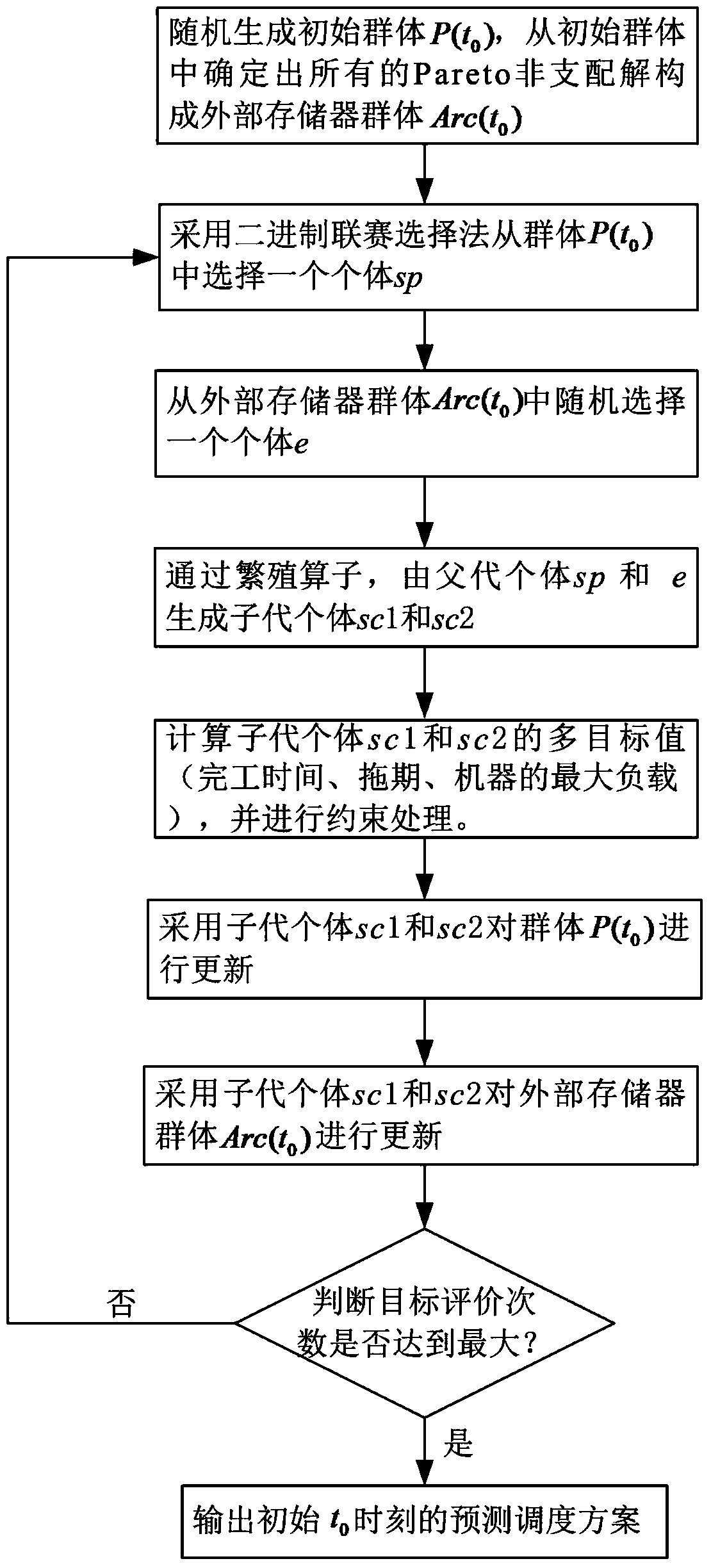

Method used

Image

Examples

Embodiment Construction

[0066] In order to better understand the technical solution of the present invention, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

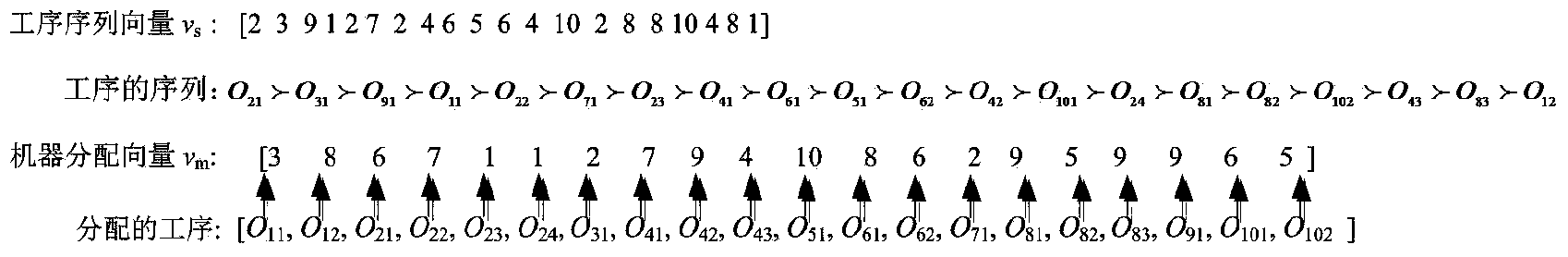

[0067] In a flexible job shop, the initial time t 0 = 0, there are 10 machines and 10 jobs to be processed. The processing deadlines, weights and the number of processes included in the 10 tasks are shown in Table 1, and the processing time is shown in Table 2. After the flexible job shop starts working, three types of dynamic events, namely "new job release", "machine failure", and "faulty machine repair", occur one after another. The time interval between failures of each machine is shown in Table 3; the repair time required for each machine after each failure is shown in Table 4; the time interval between new jobs is shown in Table 5; The processing period, weight and the number of processes involved are shown in Table 6, and the processing time is shown in Table 7. Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com