Organosilicon compounds and the use thereof for producing hydrophilic surfaces

A technology for compounds and cross-linked compositions, applied in the fields of materials, formulations, and production of hydrophilic surfaces, can solve the problems of by-products that must be removed, unavailable, expensive feedstocks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

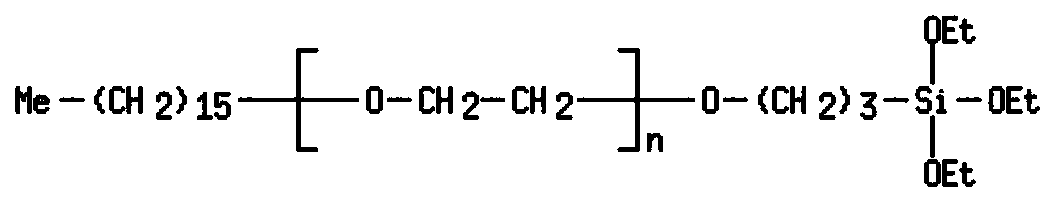

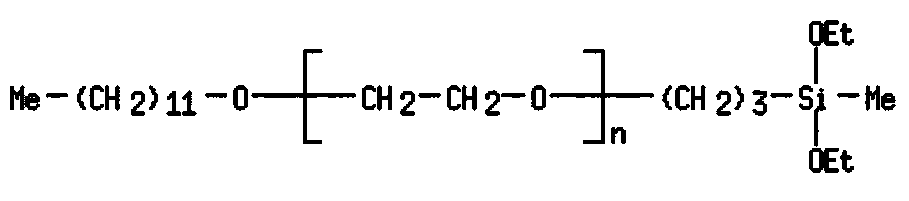

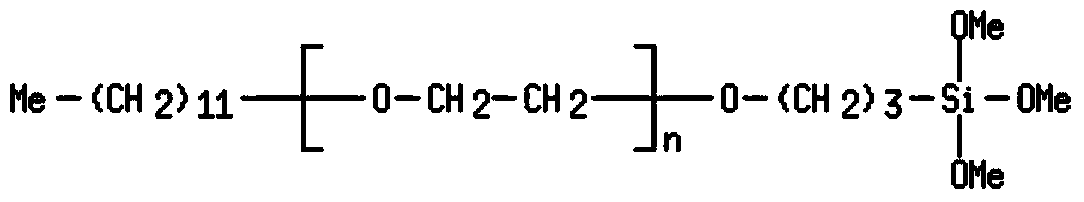

Image

Examples

Embodiment 1

[0134] Production (Product 1)

[0135] (CH 3 O) 3 Si-CH 2 CH 2 CH 2 OCH 2 CH(OH)CH 2 OC(=O)CH 2 -O(CH 2 CH 2 O) 2-6 -(CH 2 ) 11-13 CH 3 with

[0136] (CH 3 O) 3 Si-CH 2 CH 2 CH 2 OCH 2 CH(CH 2 OH)OC(=O)CH 2 -O(CH 2 CH 2 O) 2-6 -(CH 2 ) 11-13 CH 3

[0137] In a glass flask with a Lebig condenser and receiver, 100 g of glycolic acid ethoxylated lauryl ether (Mn=460 g / mol) (as AKYPO RLM 45CA from KAO Chemicals GmbH, Emmerich, Germany) Obtained) Stir at 100°C and 20 mbar until no further separation of water occurs. After the nitrogen gas was introduced, 47g of (3-glycidoxypropyl)trimethoxysilane (in the trade name GF 80, commercially available from Wacker Chemie AG, Munich, Germany) and 0.5 g of 1,4-diazabicyclo[2.2.2]octane (as Commercially available from Sigma-Aldrich Chemie GmbH, Taufkirchen, Germany), and it was stirred at 100°C for two hours. Cooling and filtering yielded 135 g of slightly yellow liquid. 13 C NMR and titration showed more than 80% adduct formation.

[0138] 1g of...

Embodiment 2

[0140] Production (Product 2)

[0141] (EtO) 3 Si-CH 2 CH 2 CH 2 OCH 2 CH(OH)CH 2 OC(=O)CH 2 -O(CH 2 CH 2 O) 5-9 -Iso-C 13 H 27 with

[0142] (EtO) 3 Si-CH 2 CH 2 CH 2 OCH 2 CH(CH 2 OH)OC(=O)CH 2 -O(CH 2 CH 2 O) 5-9 -Iso-C 13 H 27

[0143] In a glass flask with a Lebig condenser and receiver, 100 g of glycolic acid ethoxy isotridecyl ether (Mn=570 g / mol) (as Marlowet 4538, available from Sasol Germany GmbH, Hamburg, Germany) Commercially available) Stir at 100°C and 20 mbar until no further water separation occurs. After the nitrogen gas was introduced, 45g of (3-glycidoxypropyl)trimethoxysilane (in the trade name GF 82, commercially available from Wacker Chemie AG, Munich, Germany) and 0.5 g of 1,4-diazabicyclo[2.2.2]octane (as Commercially available from Sigma-Aldrich Chemie GmbH, Taufkirchen, Germany), and it was stirred at 100°C for two hours. Cooling and filtering yielded 137 g of slightly yellow liquid. 13 C NMR and titration showed more than 80% adduct formation.

[0144] ...

Embodiment 3

[0146] Production (Product 3)

[0147] (EtO) 3 Si-CH 2 CH 2 CH 2 OCH 2 CH(OH)CH 2 OC(=O)CH 2 -O(CH 2 CH 2 O) 3-7 -(CH 2 ) 8 CH=CH(CH 2 ) 5-7 CH 3 ,

[0148] with

[0149] (CH 3 O) 3 Si-CH 2 CH 2 CH 2 OCH 2 CH(CH 2 (OH))OC(=O)CH 2 -O(CH 2 CH 2 O) 3- 7 -(CH 2 ) 8 CH=CH(CH 2 ) 5-7 CH 3

[0150] In a glass flask with a Lebig condenser and receiver, 105 g of glycolic acid ethoxy oleyl ether (Mn=540 g / mol) (as AKYPO RO 50VG, available from KAO Chemicals GmbH, Emmerich, Germany) Commercially available) Stir at 100°C and 20 mbar until no further water separation occurs. After the nitrogen gas was introduced, 43g of (3-glycidoxypropyl)trimethoxysilane (in the trade name GF 80, commercially available from Wacker Chemie AG, Munich, Germany) and 0.5 g of 1,4-diazabicyclo[2.2.2]octane (as Commercially available from Sigma-Aldrich Chemie GmbH, Taufkirchen, Germany), and it was stirred at 100°C for two hours. Cooling and filtering produced 138 g of a cloudy and yellowish liquid. 13 C NMR and ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com