Measurement method for measuring elevation and flatness of concrete surface

A technology of concrete surface and measurement method, which is used in measurement devices, height/level measurement, surveying and mapping, and navigation, etc., can solve the problems of inability to detect in real time whether the flatness of the concrete top surface meets the standard inspection requirements, difficulty in elevation measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

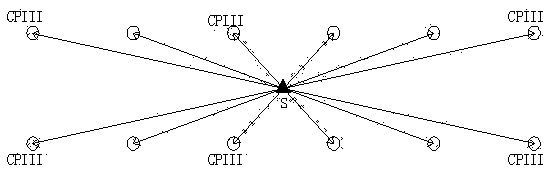

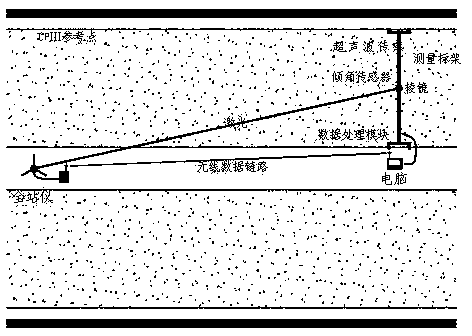

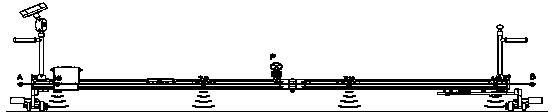

[0044]This measurement method is a non-contact intelligent measurement method, which combines the absolute measurement of the multi-directional resection of the total station and the relative measurement of the ultrasonic non-contact technology. Absolute measurement is through the resection of multiple high-precision control points around the line to obtain the three-dimensional absolute coordinates (X, Y, H) of the free station position of the total station. The three-dimensional absolute coordinates (X, Y, H) are Refers to the plane coordinates and elevation of the erection position of the total station; relative measurement refers to the relative distance between the center of the prism on the measurement frame and the position to be measured through ultrasonic non-contact measurement technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com