Helicopter rotor system elastic bearing load measuring device

A helicopter rotor and system elasticity technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of high work intensity of inspectors, poor inspection process safety, and low accuracy of inspection results, so as to reduce inspection intensity, improve inspection efficiency, and reduce work intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, the present utility model will be further described through embodiments in conjunction with the drawings.

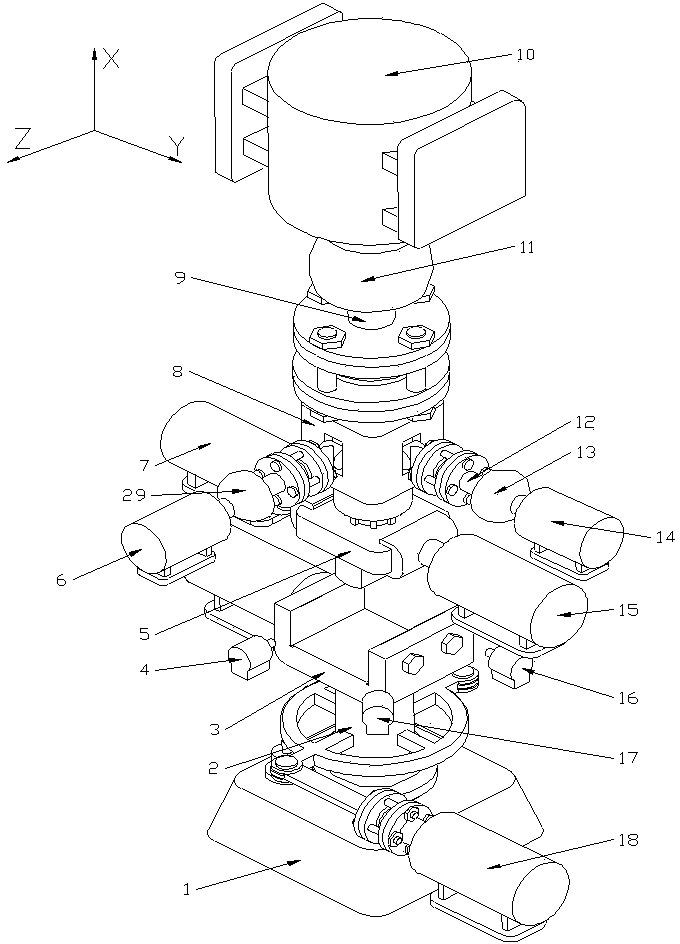

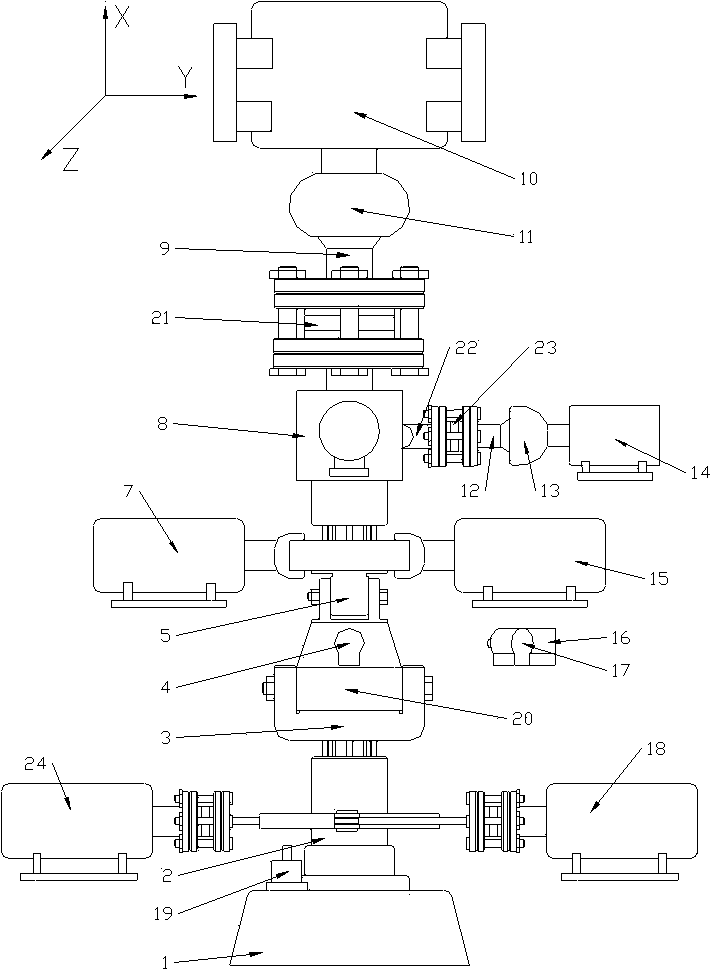

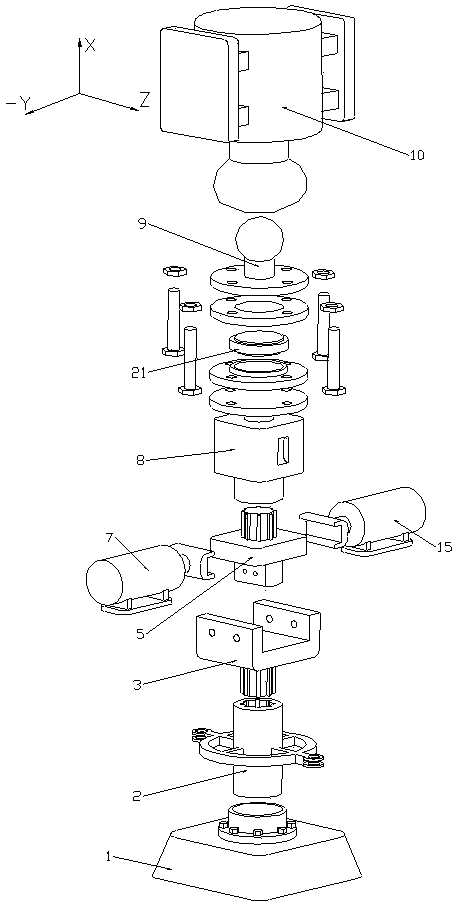

[0042] See figure 1 . An elastic bearing loading measurement device for a helicopter rotor system includes a measurement base, an X-axis testing mechanism, a Y-axis and Z-axis bending testing mechanism, an alignment locking mechanism, and an X-axis torsion testing mechanism.

[0043] See Figure 4 . The measurement base is composed of a detection table base 1, a rotating shaft 2, and a bearing large end fixture 3, and is arranged at the bottom of the equipment; the upper end of the detection table base 1 is provided with a bearing seat. The test stand base 1 is fixed on the ground and has sufficient strength to ensure the safety of the test process and the stability of the test result. The shaft core of the rotating shaft 2 is provided with a spline hole, the waist of the rotating shaft 2 is provided with a turntable, and a pair of hinge holes are symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com