Dynamic spring lead-out piece for small relay

A technology of lead-out sheet and relay, applied in relays, electromagnetic relays, electromagnetic relay details and other directions, can solve the problems of inconvenient assembly and use, lack of limit structure, etc., to achieve the effect of convenient assembly and use, and avoid the effect of left and right lateral sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

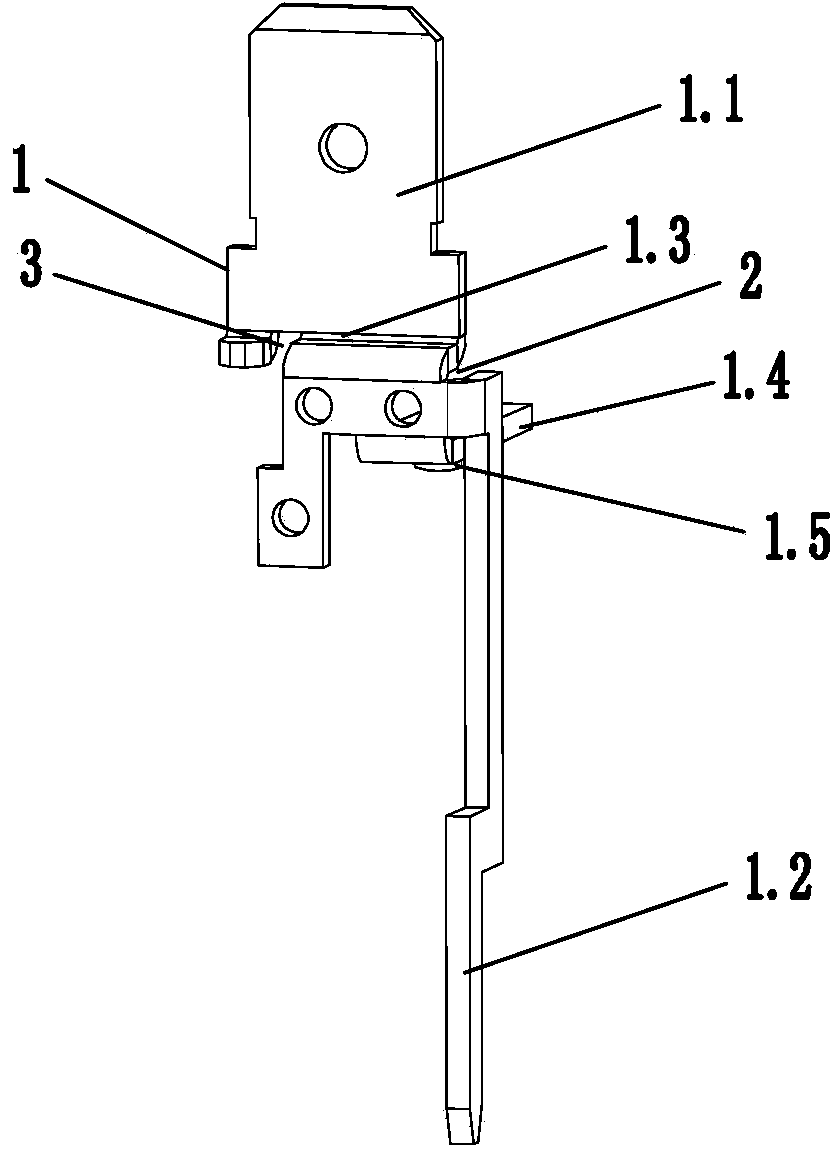

[0018] Such as figure 1 As shown, the small relay moving spring lead-out piece of the present invention includes a moving spring lead-out piece body 1, one end of the moving spring lead-out piece body 1 is provided with a connecting pin 1.1 connected to a quick connector and a wiring hole, the moving spring The other end of the spring lead-out sheet body 1 is provided with a pin 1.2 welded to the circuit board, and the bottom of the terminal pin 1.1 is provided with a first bending plate 1.3, and the pin 1.2 is located on the side of the first bending plate 1.3 , the middle part of the moving spring lead-out piece body 1 is provided with a curved second bending plate 1.4, and a first gap 2 is provided between the top of the pin 1.2 and the side wall of the first bending plate 1.3, and the pin is bent During the process, avoid its edge from pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com