Spliced type normalized shelf assembly

A storage rack and splicing technology, applied in the field of racks, can solve the problems of large waste of material scraps, tight exhibition time, long construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

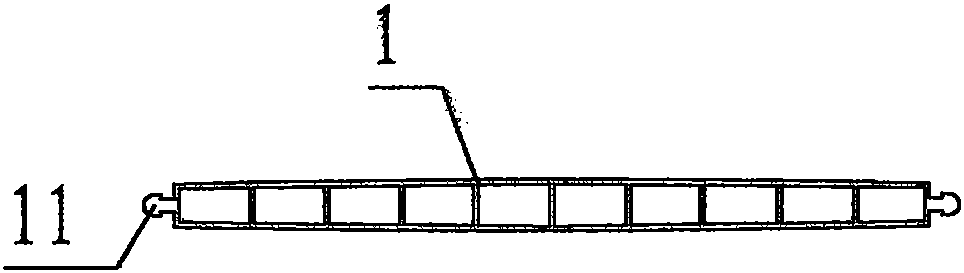

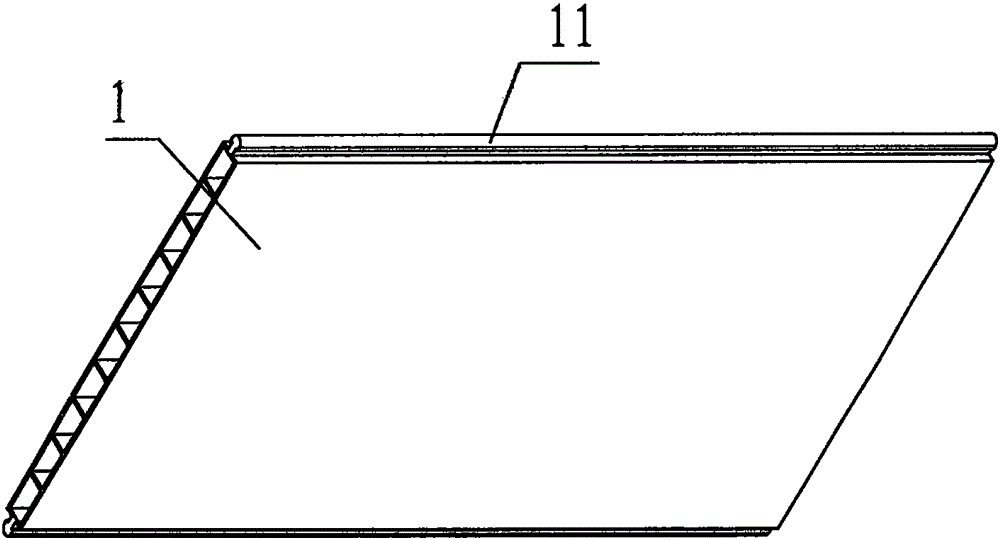

[0039] refer to Figure 1 to Figure 18 , a spliced and standardized shelf assembly of the present invention includes a frame plate 1 and a connecting strip 2, wherein: the frame plate 1 is a hollow rectangular plate-shaped plastic member, and the frame plate 1 is viewed from the front The left and right sides of the frame plate are respectively provided with circular flanges called round tenons 11, and the inside of the frame plate 1 is evenly provided with rectangular through holes formed by isolation of a number of partition walls in the front and rear directions;

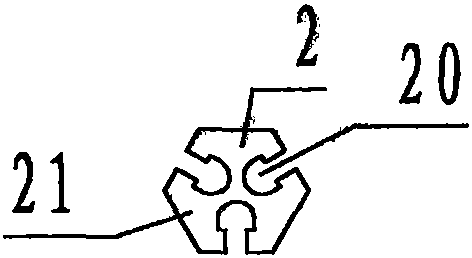

[0040] The connecting strip 2 is a long rod-shaped plastic member used to connect the frame plate 1, and a number of circular, front-to-back transparent grooves are arranged along the long side of the connecting strip 2 in the front view. Round head groove 20, said round head groove 20 is used for corresponding sliding fit with said round head tenon 11 of frame plate 1;

[0041] The connecting strips 2 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com