Wellhead heating device for supercritical carbon dioxide fracturing of oil and gas wells

A carbon dioxide and heating device technology, which is applied to isolation devices, wellbore/well components, and production fluids, etc., can solve the problems of increasing pipeline modification procedures, large area, and complicated operation, and achieves simple structure, convenient operation, The effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

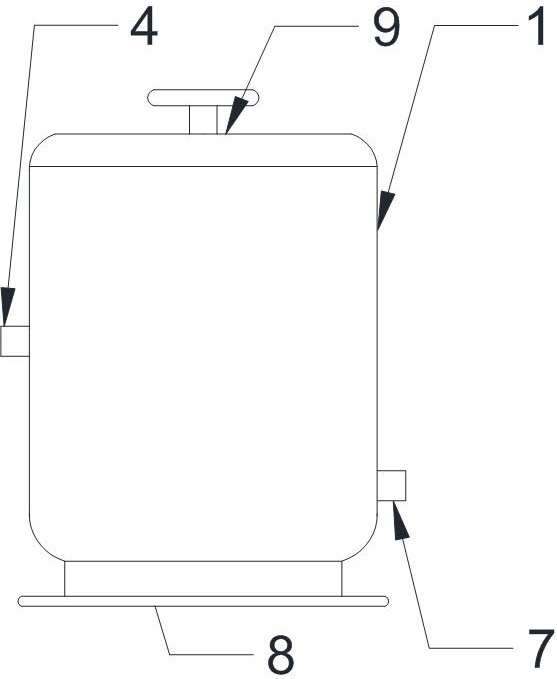

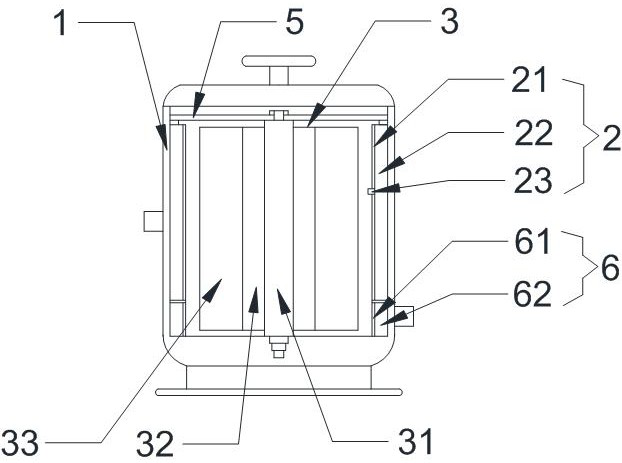

[0038] This embodiment provides a wellhead heating device for supercritical carbon dioxide fracturing of oil and gas wells, including a casing 1 and a heating mechanism, the heating mechanism includes a preheating assembly 2 and a heating assembly 3, and the casing 1 adopts a pressure-resistant cylindrical structure.

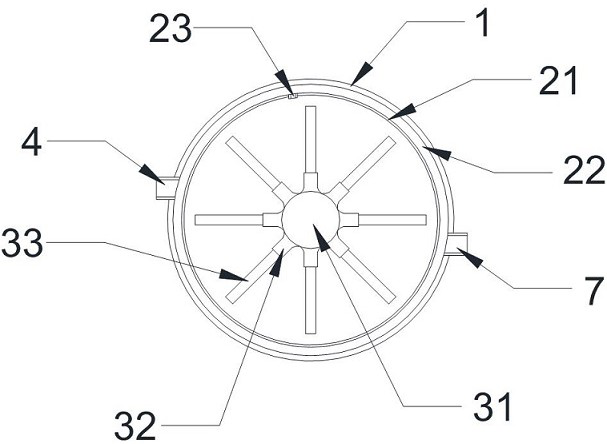

[0039]The preheating assembly 2 includes an isolation cylinder I21, the isolation cylinder I21 adopts a pressure-resistant cylindrical structure, the isolation cylinder I21 is coaxially arranged in the casing 1, and the annular chamber between the outer wall of the isolation cylinder I21 and the inner wall of the casing 1 serves as a preheating chamber twenty two.

[0040] The heating assembly 3 includes a rotating shaft 31, a reversing baffle plate 32 and an electric heating element 33; the rotating shaft 31 is rotatably installed in the casing 1 through a connecting piece, and the axis of the rotating shaft 31 coincides with the axis of the casing 1; The plate...

Embodiment 2

[0044] This embodiment provides a wellhead heating device for supercritical carbon dioxide fracturing of oil and gas wells, which is further improved on the basis of Embodiment 1. The preheating assembly 2 is provided with an inlet and an outlet 23; The inlet port 4 on the upper part is connected; the diameter of the outlet 23 is smaller than the inner diameter of the preheating chamber 22 . The direction of the output airflow from the outlet 23 faces between two adjacent reversing baffles 32 , preferably, the direction of the output airflow faces between two adjacent reversing baffles 32 , and is biased toward a certain reversing baffle 32 .

[0045] CO pressurized by fracturing pump truck 2 The fluid enters the preheating chamber 22 through the air inlet port 4 through the pipeline, is preheated in the preheating chamber 22 , and then enters the casing 1 through the outlet 23 . The diameter of the designed outlet 23 is smaller than the inner diameter of the preheating chamb...

Embodiment 3

[0047] This embodiment provides a wellhead heating device for supercritical carbon dioxide fracturing of oil and gas wells, which is further improved on the basis of Embodiment 2. The plurality of reversing baffles 32 are evenly distributed at equal intervals along the circumference of the rotating shaft 31 . Each reversing baffle 32 corresponds to a plurality of electric heating elements 33 , the first electric heating element 33 is installed on the side wall of the reversing baffle 32 , and the remaining electric heating elements 33 are adjacent to each other and extend in a direction away from the rotating shaft 31 in sequence. , and the adjacent electric heating elements 33 are detachably connected. The structure of each electric heating element 33 is the same, and the following design is adopted: the electric heating element 33 includes an upper support 331, a lower support 332 and an electric heater 333;

[0048] The upper support 331 and the lower support 332 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com