Composite material electric pole of braided structure

A composite material and pole technology, which is used in woven fabrics, textiles, papermaking, construction, etc., can solve the problems of inconvenient installation and transportation, long service life, high mechanical strength of ferroelectric poles, etc. Insulation and anti-corrosion effect, the effect of easy line connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

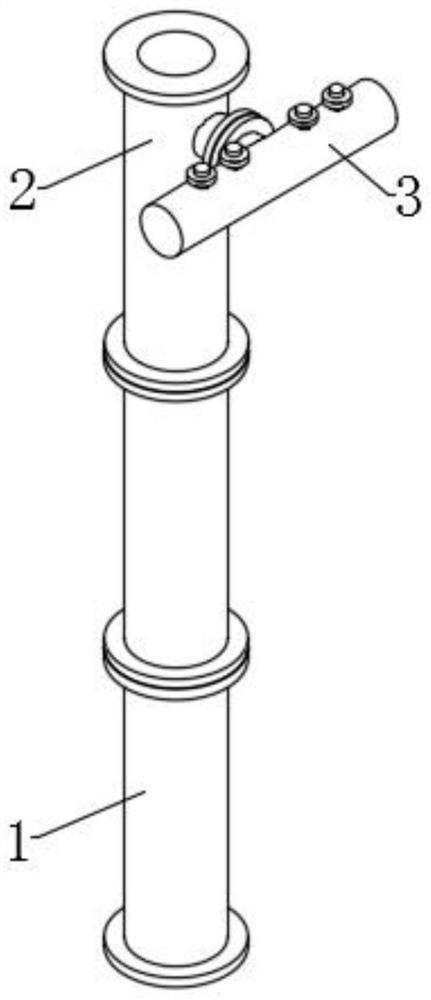

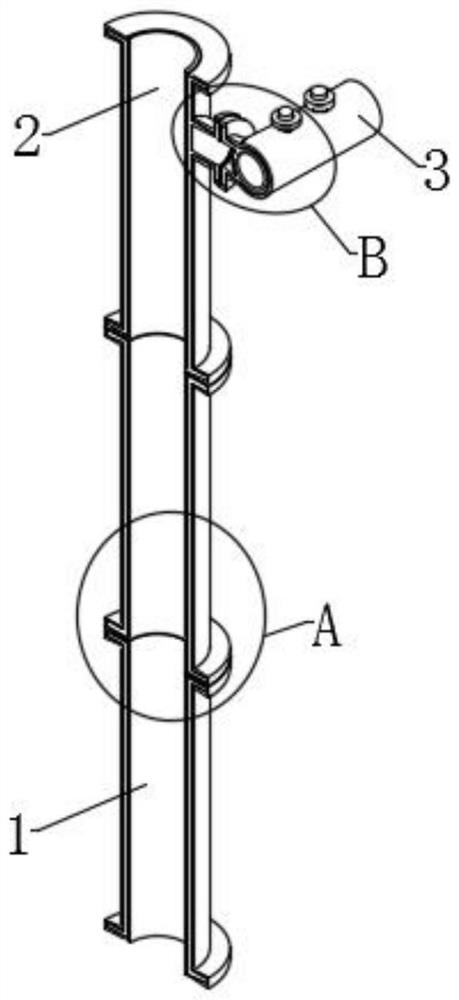

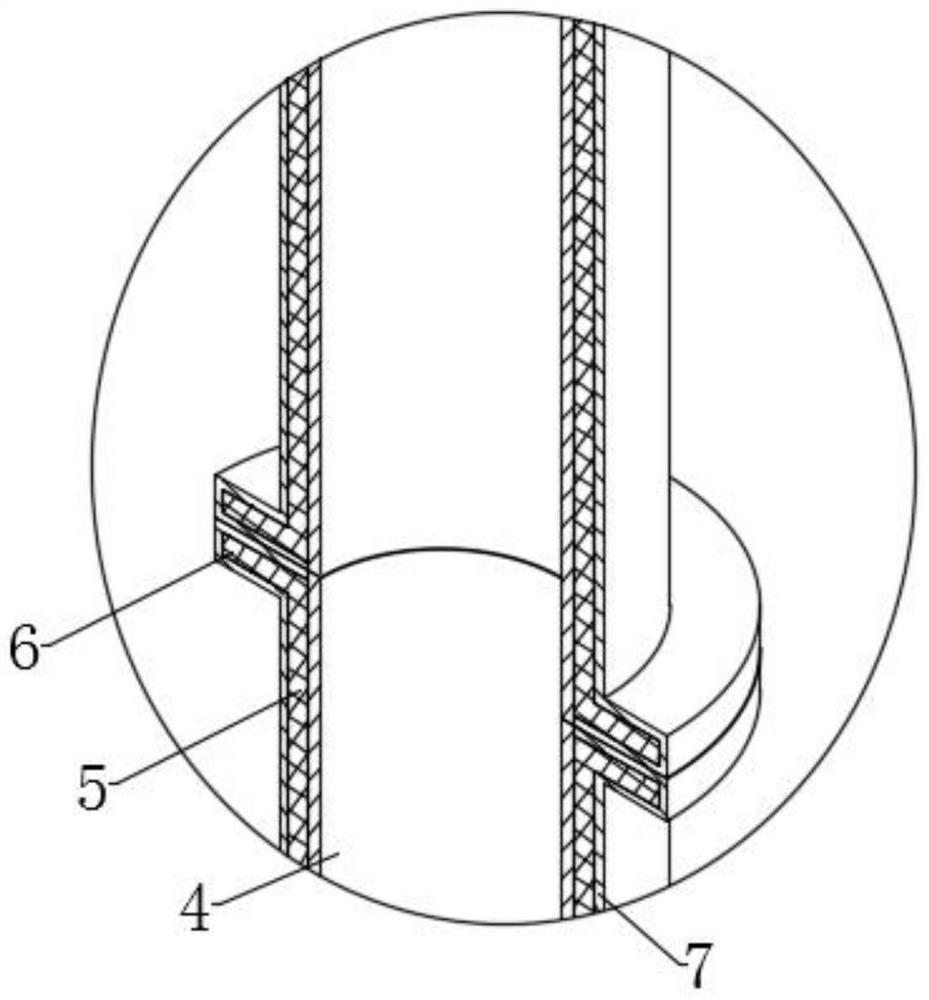

[0026] Embodiment 1: as Figure 1 to Figure 4 As shown, the present invention provides a composite pole with braided structure, including a shaft 1, a rod end 2 and a cross arm 3, the shaft 1 includes a first profile 5, and the rod end 2 and the cross arm 3 include a second profile 8. The peripheral outer wall of the second profile 8 is integrally formed with a second flange ring 9, and the two ends of the first profile 5 and the two ends of the second profile 8 at the rod end 2 are integrally formed with a first flange ring 6. The outer wall of the second profile 8 at the cross arm 3 is integrally formed with a plurality of terminals 10, the inner cavities of the first profile 5 and the second profile 8 are provided with an inner braiding layer 4, the first profile 5 and the second profile 8 The outer walls of each are provided with an outer braided layer 7.

[0027] Further, the first flange ring 6 , the second flange ring 9 and the terminal 10 are all covered in the outer ...

Embodiment 2

[0034] Embodiment 2: as Figure 1 to Figure 4 As shown, the present invention provides a composite pole with braided structure, including a shaft 1, a rod end 2 and a cross arm 3, the shaft 1 includes a first profile 5, and the rod end 2 and the cross arm 3 include a second profile 8. The peripheral outer wall of the second profile 8 is integrally formed with a second flange ring 9, and the two ends of the first profile 5 and the two ends of the second profile 8 at the rod end 2 are integrally formed with a first flange ring 6. The outer wall of the second profile 8 at the cross arm 3 is integrally formed with a plurality of terminals 10, the inner cavities of the first profile 5 and the second profile 8 are provided with an inner braiding layer 4, the first profile 5 and the second profile 8 The outer walls of each are provided with an outer braided layer 7.

[0035] Further, the first flange ring 6 , the second flange ring 9 and the terminal 10 are all covered in the outer ...

Embodiment 3

[0042] Embodiment 3: as Figure 1 to Figure 4 As shown, the present invention provides a composite pole with braided structure, including a shaft 1, a rod end 2 and a cross arm 3, the shaft 1 includes a first profile 5, and the rod end 2 and the cross arm 3 include a second profile 8. The peripheral outer wall of the second profile 8 is integrally formed with a second flange ring 9, and the two ends of the first profile 5 and the two ends of the second profile 8 at the rod end 2 are integrally formed with a first flange ring 6. The outer wall of the second profile 8 at the cross arm 3 is integrally formed with a plurality of terminals 10, the inner cavities of the first profile 5 and the second profile 8 are provided with an inner braiding layer 4, the first profile 5 and the second profile 8 The outer walls of each are provided with an outer braided layer 7.

[0043] Further, the first flange ring 6 , the second flange ring 9 and the terminal 10 are all covered in the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com