Light-emitting diode and encapsulating method thereof

A technology of light-emitting diodes and packaging methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of uneven distribution of phosphor powder, and achieve the effect of uniform light mixing and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

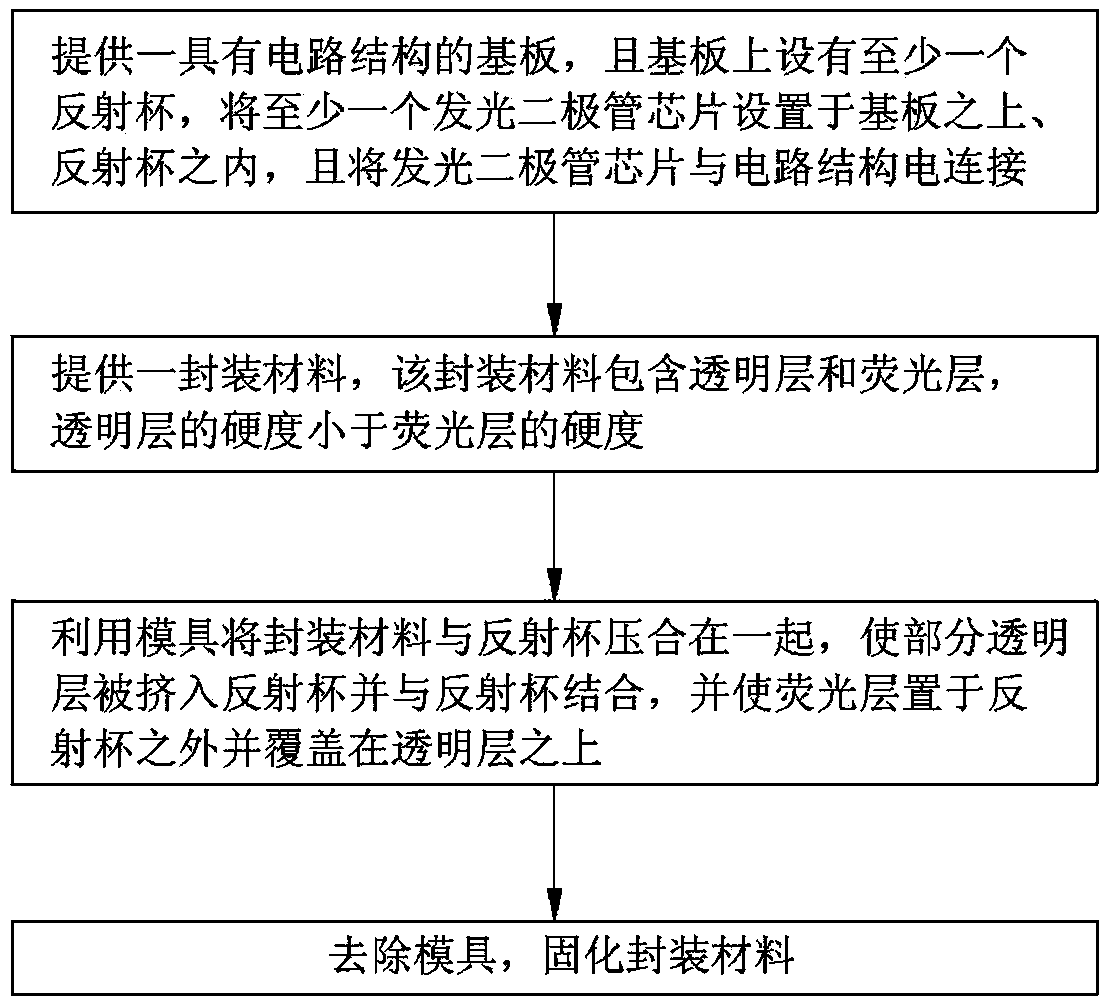

[0021] The flow process of the light-emitting diode packaging method provided by the invention is as follows: figure 1 shown.

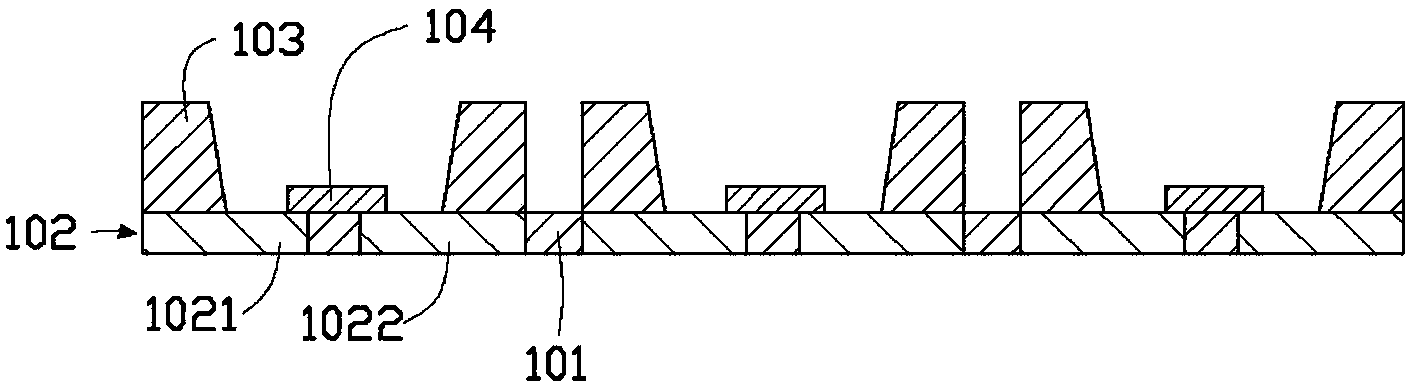

[0022] Step 1: See figure 2 , provide a substrate 101 with a circuit structure 102, and at least one reflective cup 103 is provided on the substrate 101, at least one light-emitting diode chip 104 is respectively arranged on the substrate 101 and in the reflective cup 103, and the light-emitting diode chip 104 It is electrically connected with the circuit structure 102 . The circuit structure 102 includes at least one first electrode 1021 and at least one second electrode 1022 .

[0023] In this embodiment, a packaging method for mass producing a plurality of light emitting diodes is provided, such as figure 2 As shown, a substrate 101 with a circuit structure 102 forming a set of strip structures is provided, and the strip str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com