Strip rolling reduction rate control method of double-rack four-roller mill

A four-high mill and strip rolling technology, applied in the direction of tension/pressure control, etc., can solve the problems of customer loss, long transformation period, affecting the market supply of enterprises, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

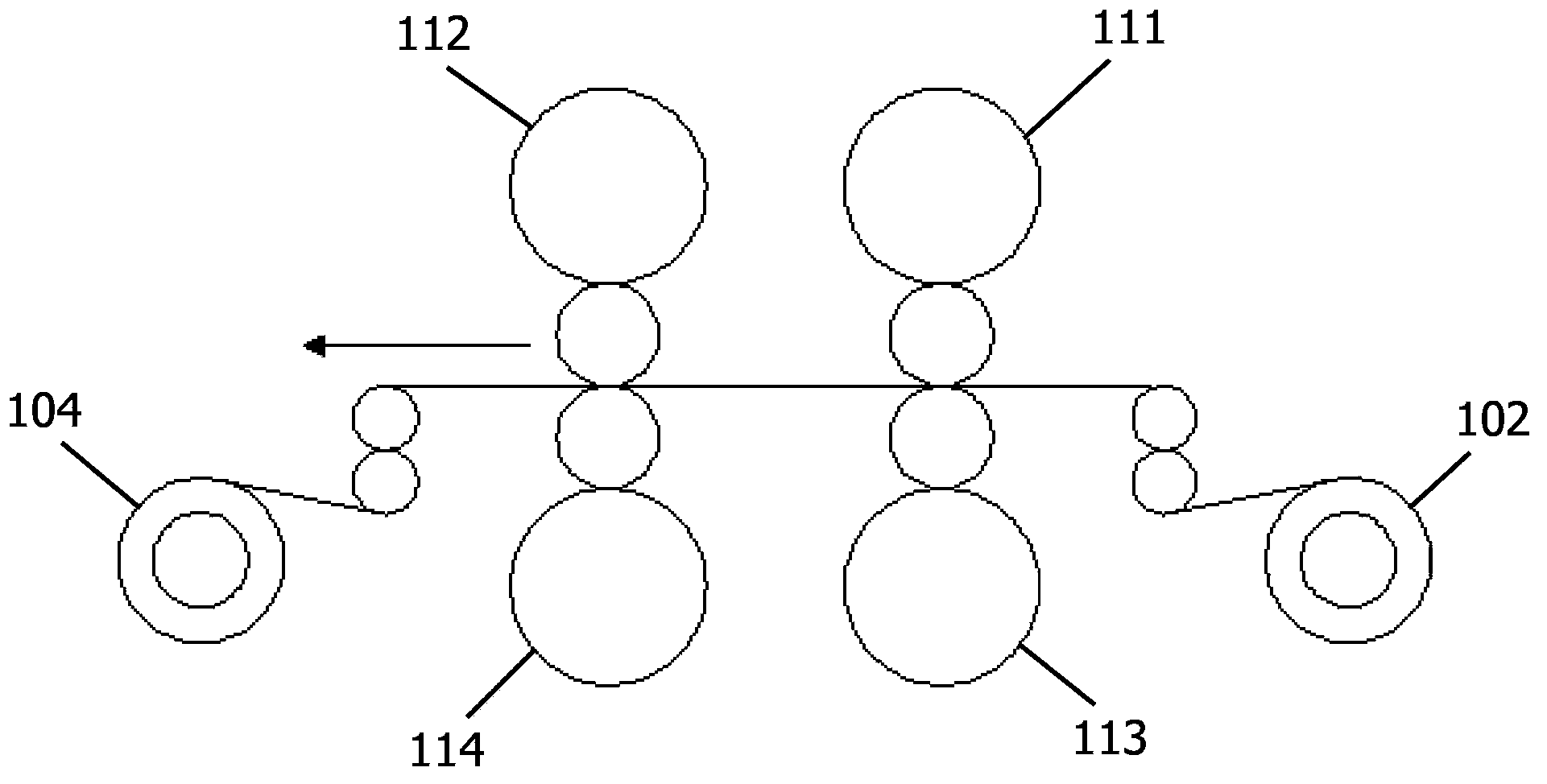

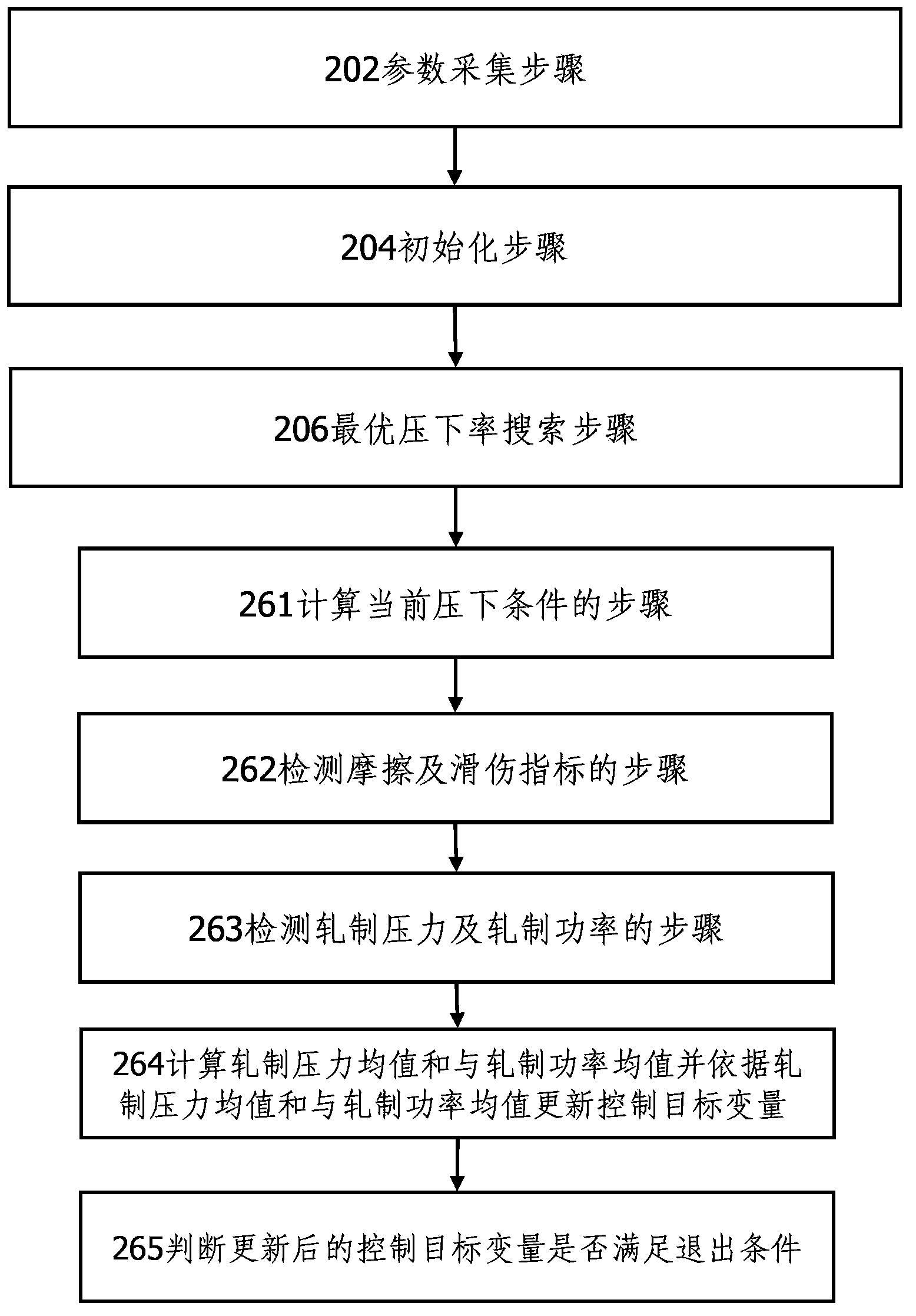

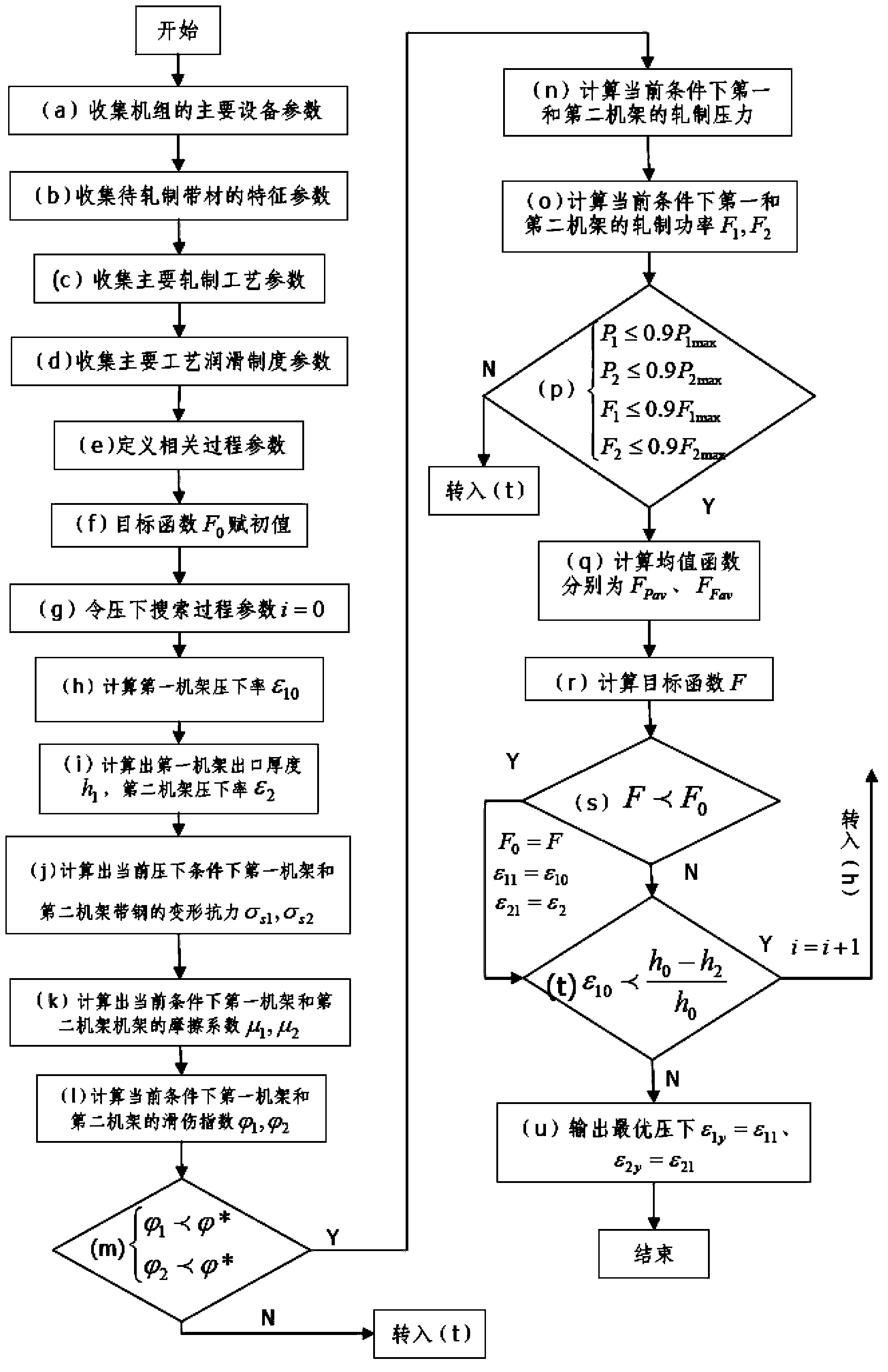

[0105] Taking a double-stand 1420 rolling mill as an example, with the help of image 3 to describe the rolling reduction setting process for high-grade automotive sheet of a specific specification.

[0106] Firstly, in step 1, the main equipment parameters of the two-stand four-high rolling mill to be set are collected, mainly including the diameters of the work rolls of the first stand and the second stand =450mm, =500mm, the maximum rolling pressure P of the first stand and the second stand rolling mill 1max =1800t,P 2max =1800t, the maximum rolling power F of the first stand and the second stand rolling mill 1max =4000Kw, F 2max =4000Kw;

[0107] Subsequently, in step 2, the characteristic parameters of the strip to be rolled are collected, mainly including: the width B=1200mm of the strip; the thickness h of the incoming strip 0 =0.9mm; the modulus of elasticity of the strip E=2.1×10 5 MPa; Poisson's ratio v=0.3 of the strip; initial deformation resistance σ of t...

no. 2 approach

[0131] In order to further illustrate the implementation process of this patent, taking a certain double-stand 1550 rolling mill as an example, with the help of image 3 to describe the rolling reduction setting process for high-grade automotive sheet of a specific specification.

[0132] Firstly, in step 1, the main equipment parameters of the double-stand 1550 four-high rolling mill to be set are collected, mainly including the diameters of the work rolls of the first stand and the second stand =415mm, =460mm, the maximum rolling pressure P of the first stand and the second stand rolling mill 1max =2000t,P 2max =2000t, the maximum rolling power F of the first stand and the second stand rolling mill 1max =4500Kw, F 2max =4500Kw;

[0133] Subsequently, in step 2, the characteristic parameters of the strip to be rolled are collected, mainly including: the width B=1320mm of the strip; the thickness h of the incoming strip 0 =1.20mm; the modulus of elasticity of the strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com