Manufacturing technology for regenerated bark with high-tearing and high-peeling properties

A manufacturing process and high-peeling technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve problems such as human health hazards, hereditary gene defects, chromium soil pollution, etc., achieve reduced production and consumption costs, simple structure, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

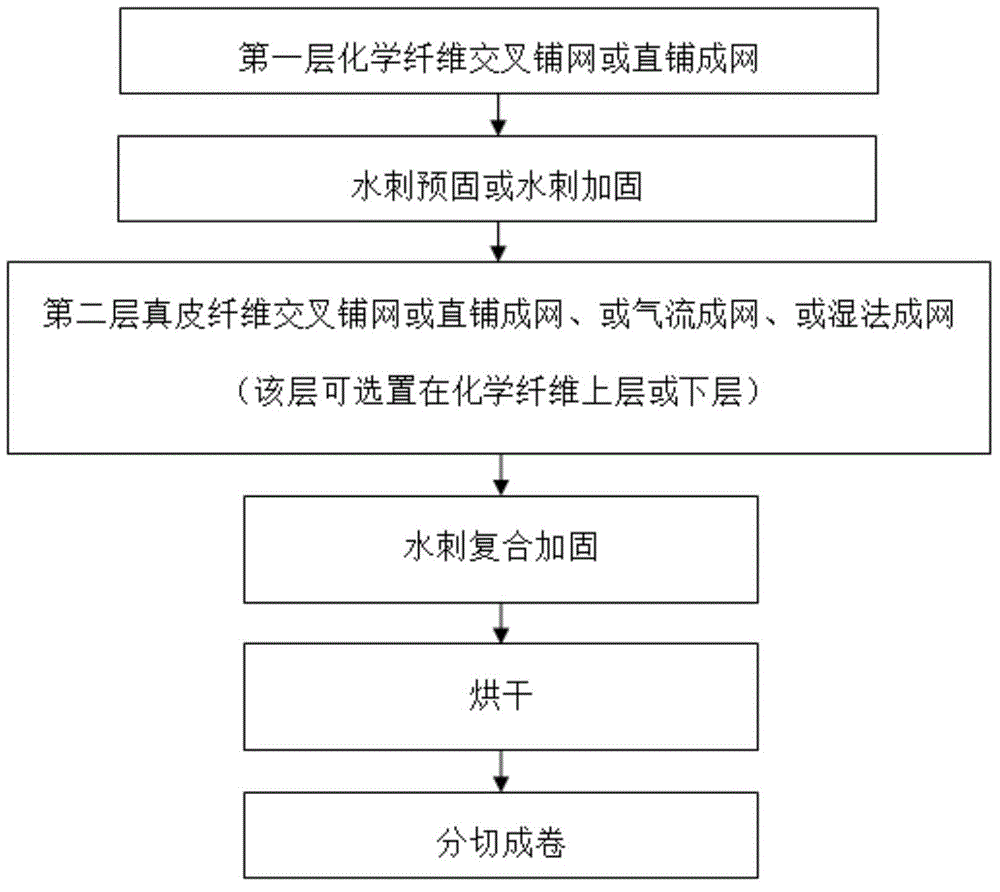

[0030] see figure 1 , in the embodiment of the present invention, the manufacturing process of high-tear and high-peeling recycled leather includes the following steps: (1) the first layer of chemical fibers is cross-laid or straight-laid into a web; (2) spunlace pre-consolidated or spunlace reinforced ; (3) The second layer of leather fibers is cross-laid or directly formed into a network; (4) The second layer of leather fibers is selected to be placed on the upper or lower layer of the first layer of chemical fibers according to the process requirements, and then spunlace composite reinforcement, drying Dried, cut into rolls.

Embodiment 2

[0032] see figure 1 , in the embodiment of the present invention, the manufacturing process of high-tear and high-peeling recycled leather includes the following steps: (1) the first layer of chemical fibers is cross-laid or straight-laid into a web; (2) spunlace pre-consolidated or spunlace reinforced ; (3) The second layer of leather fiber is air-laid; (4) The second layer of leather fiber is placed on the upper or lower layer of the first layer of chemical fiber according to the process requirements, and then spunlace composite reinforcement, drying, and cutting into rolls.

Embodiment 3

[0034] see figure 1 , in the embodiment of the present invention, the manufacturing process of high-tear and high-peeling recycled leather includes the following steps: (1) the first layer of chemical fibers is cross-laid or straight-laid into a web; (2) spunlace pre-consolidated or spunlace reinforced ; (3) The second layer of leather fiber is wet-laid; (4) The second layer of leather fiber is placed on the upper layer or lower layer of the first layer of chemical fiber according to the process requirements, and the spunlace composite reinforcement, drying, and separation are carried out. Cut into rolls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com