Drawing mould

A technology for deep drawing dies and concave dies, which is applied in metal processing equipment, forming tools, manufacturing tools, etc. It can solve problems such as difficult adjustment of blank holder force, high friction force, possibility of wrinkling and cracking in deep drawing, and achieve reduction The effect of limit drawing coefficient, cost saving and plate saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

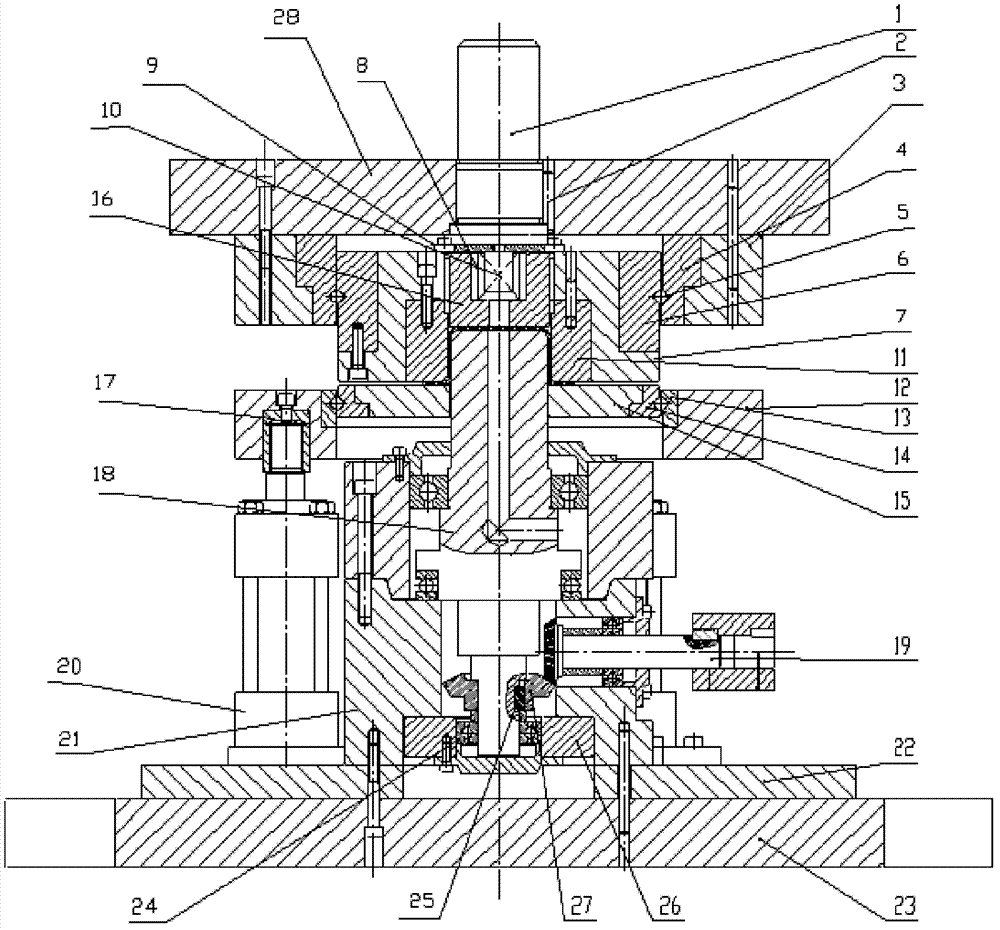

[0024] see figure 1 , when the deep drawing die is working, the punch shaft 18 is driven to rotate by a pair of bevel gears 27 and the key 25, the die 11 is lowered, and the blank holder structure is in a non-working state. When the die is close to the blank holder structure, The hydraulic pressure of the blank holder makes the sheet close to the lower turntable structure and the die 11, and then descends together. When the sheet touches the punch shaft 18, the punch shaft 18 drives the sheet to rotate, and the die 11, the upper turntable The structure and the lower turntable structure are driven by the plate to rotate together, while the die 11 and the lower turntable structure continue to descend until drawing and forming. The specific structure of the drawing die is described below:

[0025] The drawing die involved in the present invention includes a die structure, a blank holder and a punch structure.

[0026] The die structure includes: upper die seat plate 28, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com