A deep drawing forming method of a deep cylindrical part and its mold

A technology for deep cylindrical parts and forming molds, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency, achieve the effects of improving forming quality, reducing material diameter, and reducing work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

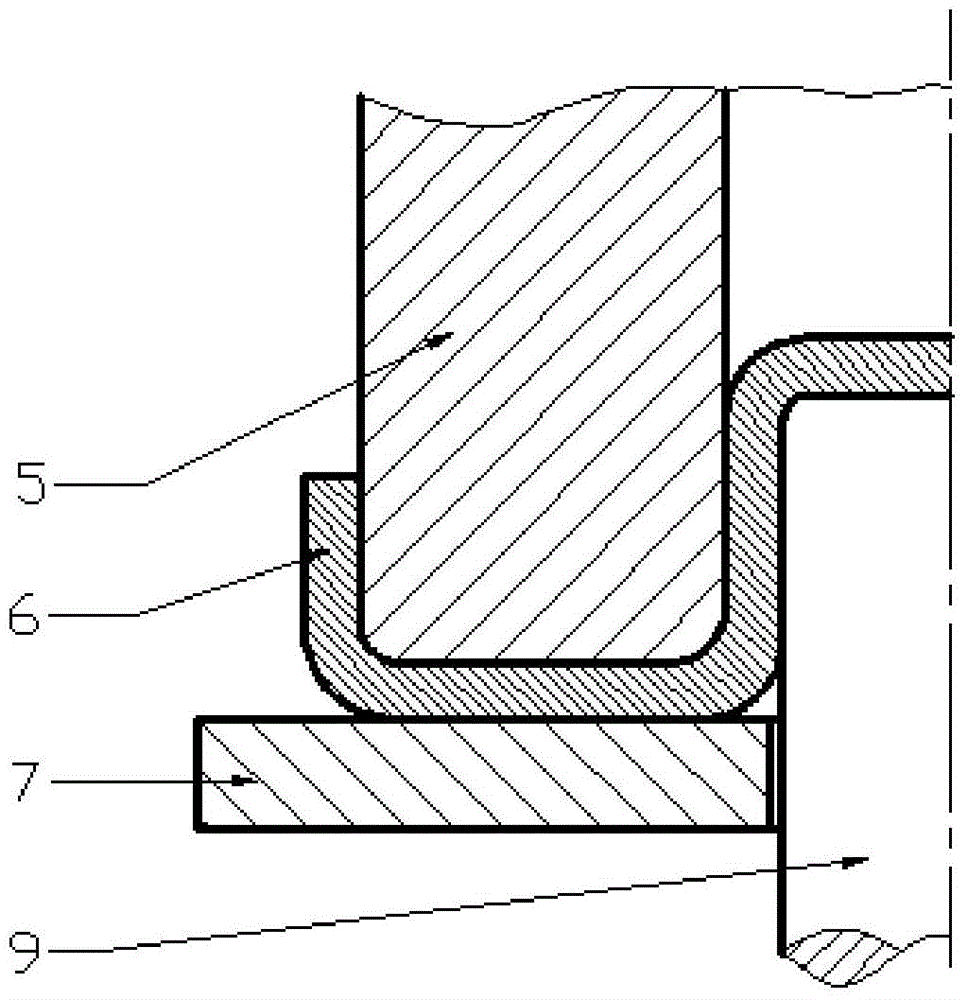

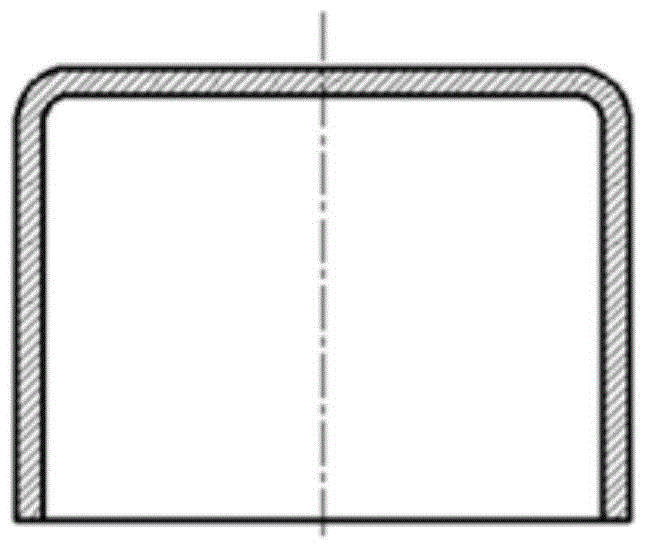

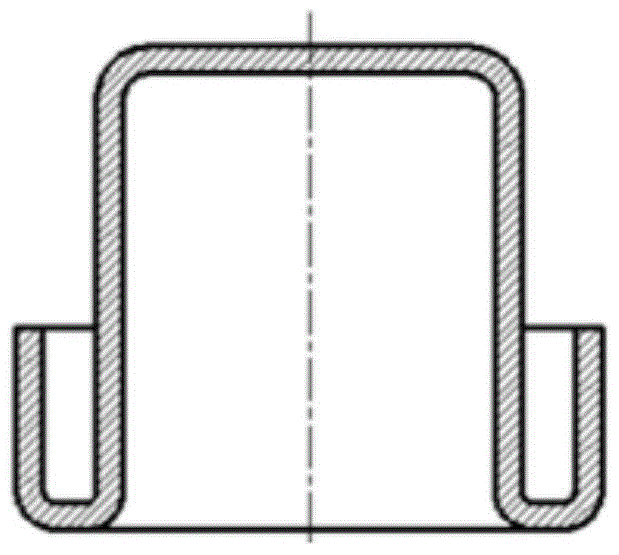

[0031] Such as Figures 1 to 5 shown. The present invention is a kind of deep-drawing forming mold for cylindrical parts, comprising a die 5, a punch 9 corresponding to the die 5, and a blank holder 7 sleeved on the punch 9; wherein, on the bottom surface of the die 5 and On the surface of the blank holder 7 corresponding to the bottom surface, there are drawn sill structures corresponding to and matched with each other.

[0032] The deep-drawing sill structure is a stepped deep-drawing sill composed of a raised stepped surface on the bottom surface of the die 5 and a corresponding concave stepped surface on the surface of the blank holder 7; During deep drawing, the stepped drawing sill presses the edge of the sheet metal, and the sheet material flows between the stepped drawing sills. Arc transition between the steps of the stepped deep-drawn sill.

[0033] The height of the stepped drawing sill is C=(0.2~0.5)t, where t is the sheet thickness of the drawing part.

[0034...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com