Wet tensile rewinding equipment

A technology for rewinding and equipment, applied in the field of monofilament rewinding equipment, can solve problems such as hidden safety hazards, damage to finished monofilament and traction drawing dies, easy generation of friction and high temperature, etc., and achieve improvement and reduction of tensile strength indicators. The pulling force of each pass, the effect of satisfying the repair circle diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

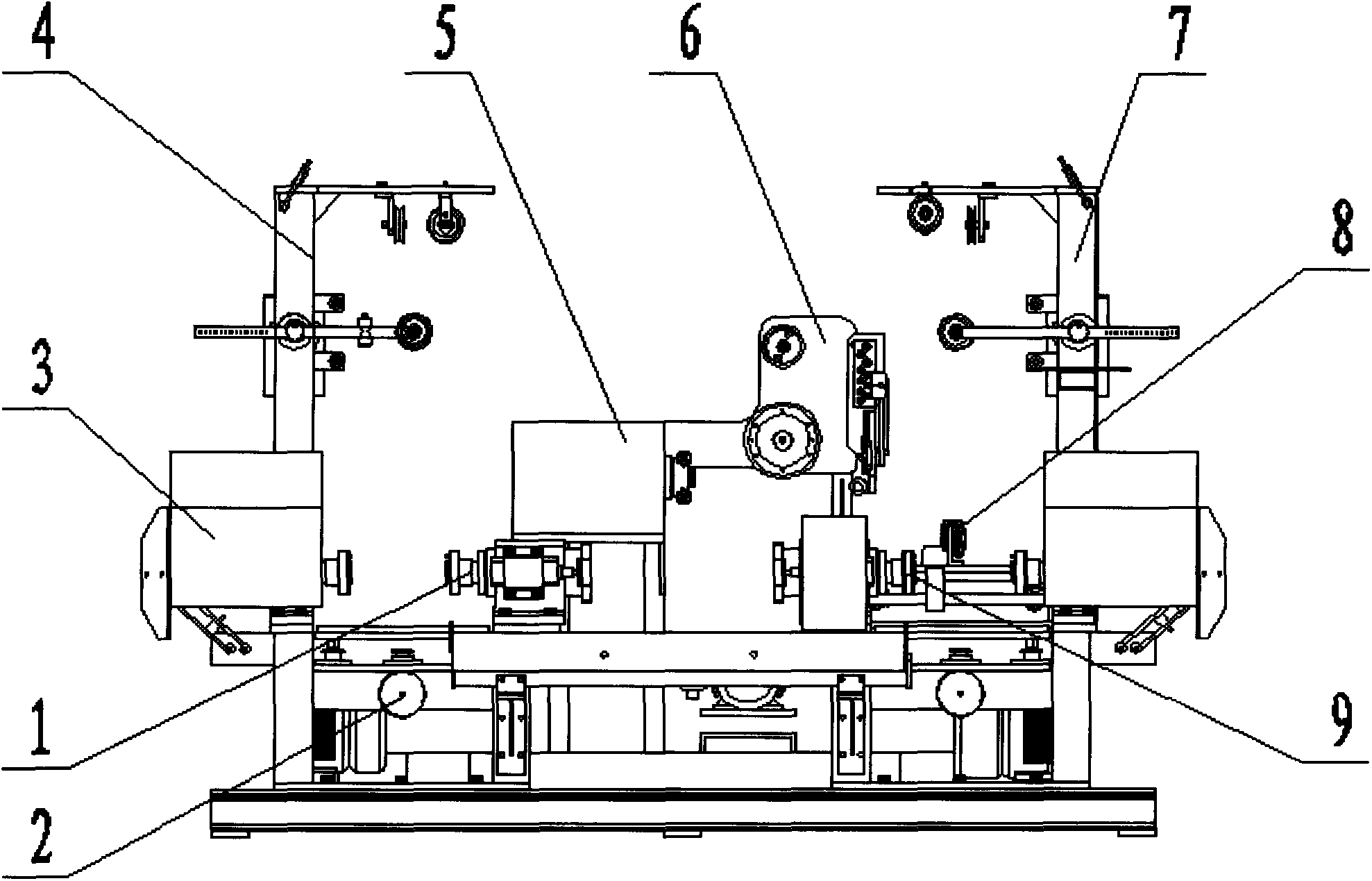

[0011] figure 1 As shown, a wet drawing and rewinding equipment includes a pay-off mechanism 1, a lifting mechanism 2, a protective door mechanism 3, a pay-off tension mechanism 4, a lubricating pool 5, a pulling mechanism 6, a take-up tension mechanism 7, and a cable guide 8 and take-up mechanism 9. The pay-off mechanism 1 and the take-up mechanism 9 are respectively supported on the lifting mechanism 2; the pay-off mechanism 1 and the take-up mechanism 9 are connected with a protective door mechanism 3; the protective door mechanism 3 is connected with the pay-off mechanism 1, the take-up mechanism 9 and Traction and drawing mechanism 6; both the pay-off mechanism 1 and the take-up mechanism 9 are equipped with a cable guide 8, and the take-off mechanism 1 passes through the pay-off tension mechanism 4, the lubrication pool 5, the traction and pull mechanism 6, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com