Small space socket head cap screw mounting and dismounting tool

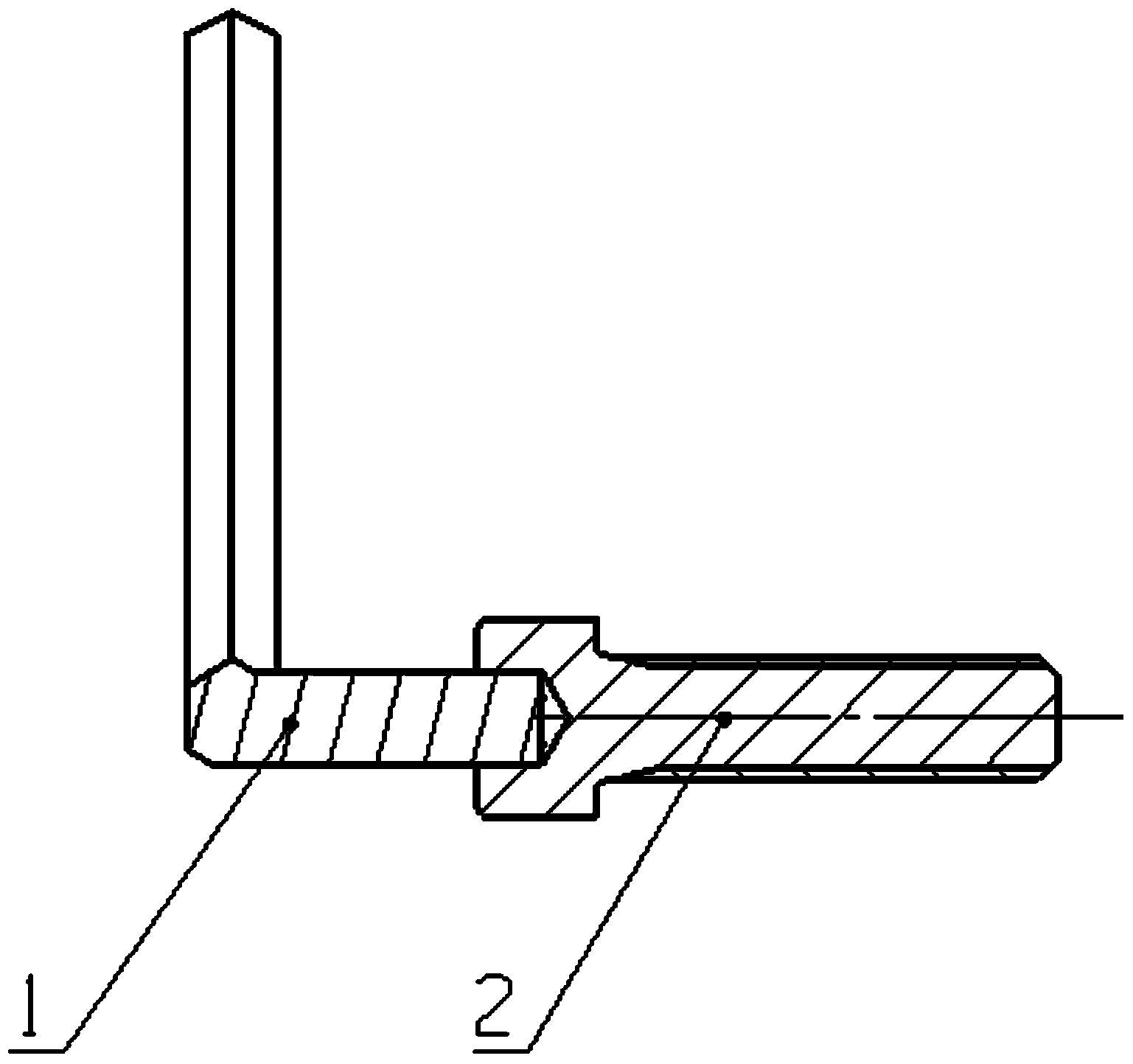

A hexagonal screw and hollow screw technology, which is applied in the manufacture of tools, screwdrivers, wrenches, etc. It can solve the problems that the hexagonal wrench 1 cannot be placed in the hexagonal screw, the screw cannot be placed accurately, and the hexagonal screw 2 cannot be fixed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

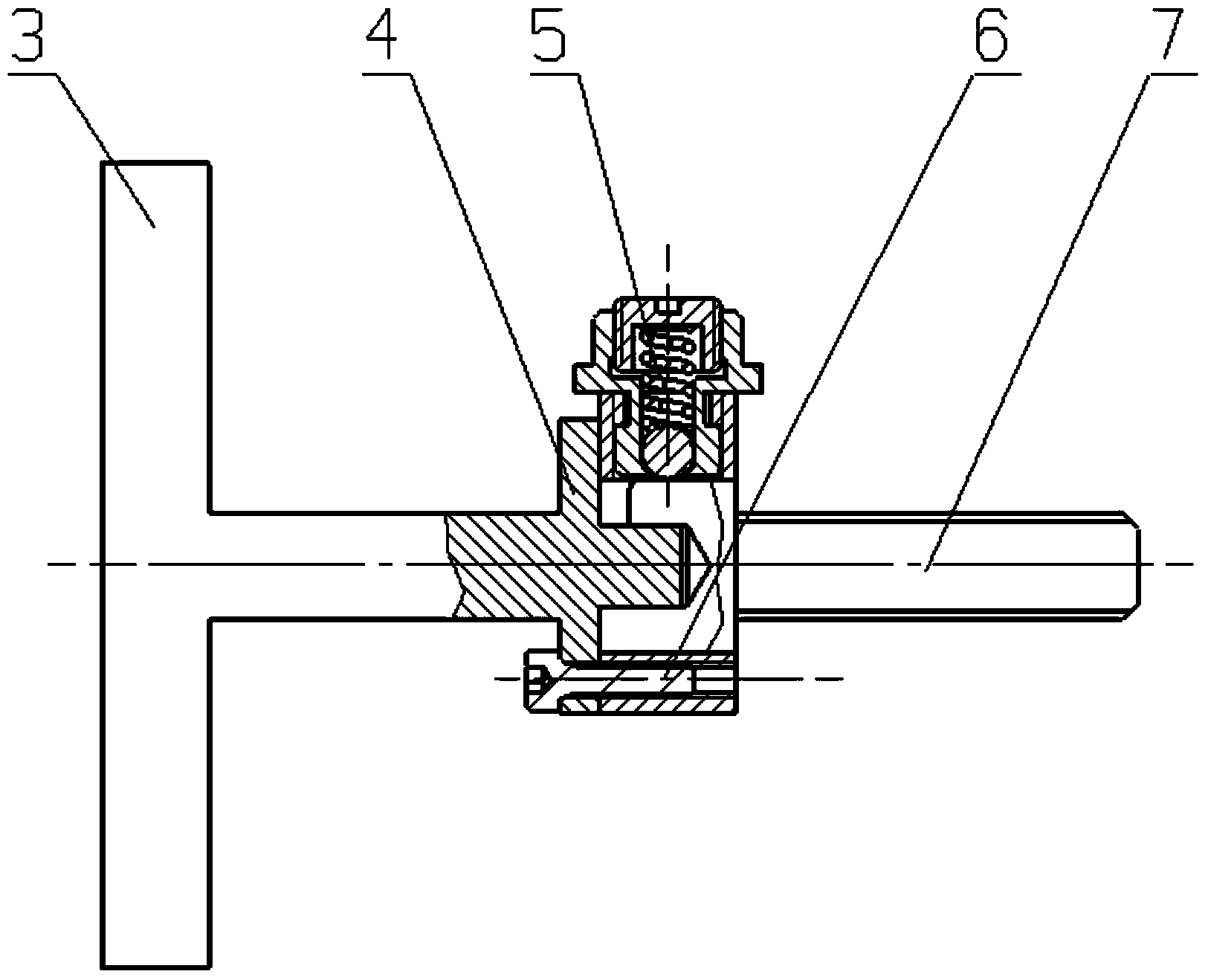

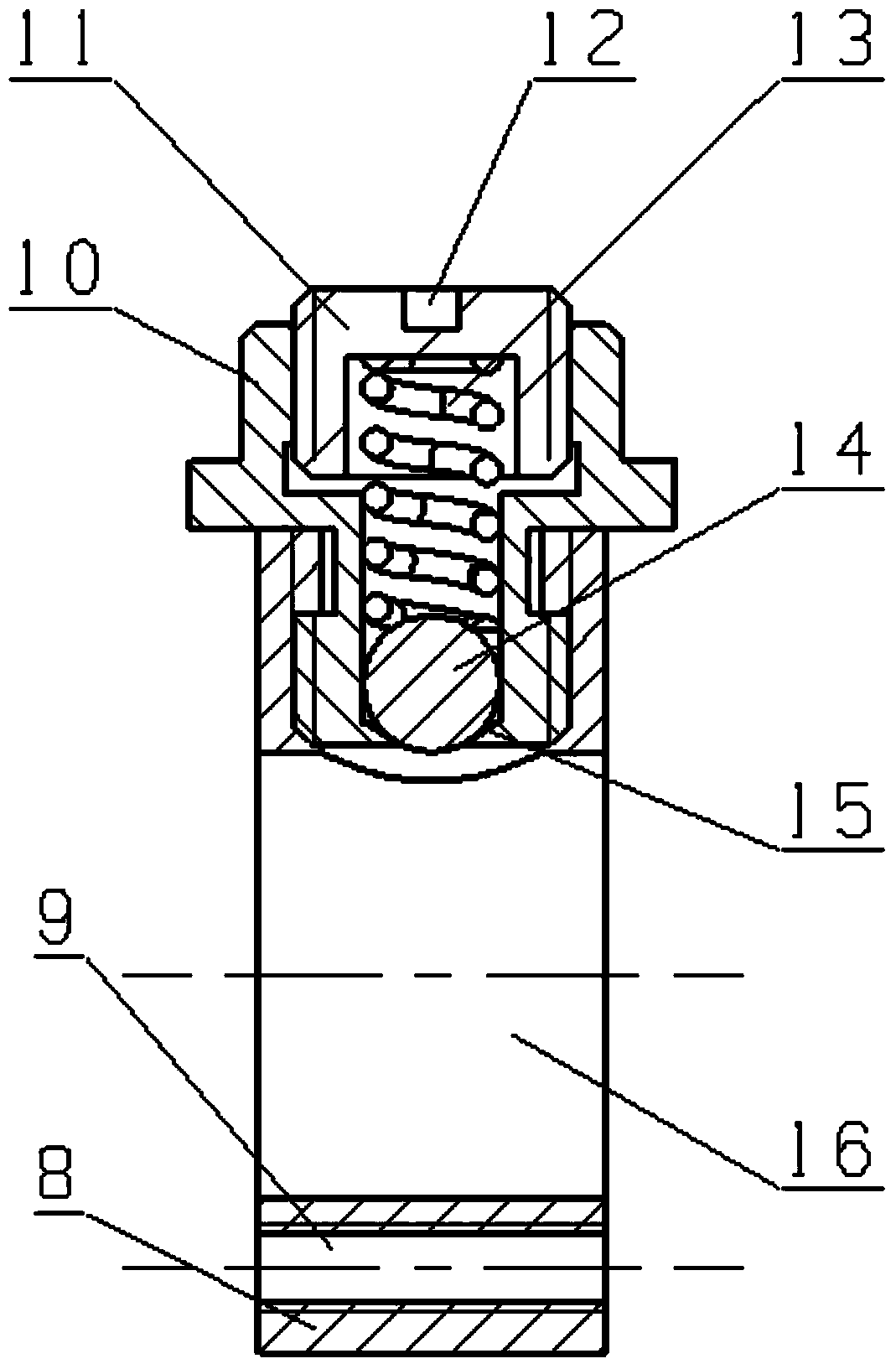

[0013] The invention according to figure 2 , image 3 The structure shown is implemented. Wherein including long bar hex wrench 3, screw 6, hexagon socket screw 7, fixed ring 8, hollow screw rod 10, hollow nut 11, steel ball 14 material adopts Q235; Spring 13 material adopts 65Mn.

[0014] The elastic compression fixing device 5 is fixed together with the head connection plate 4 on the long rod Allen wrench 3 by the threaded hole 9 on the fixing ring 8; the hollow screw rod 10 is fixed on the fixing ring 8 by threaded connection, Steel ball 14 is loaded into the hollow screw 10, and a 120° cone angle is processed at the bottom of the hollow hole of the hollow screw 10, and the steel ball 14 falls on the 120° cone angle hole 15 on the hollow screw 10, and the 120° cone angle hole 15 The diameter is less than the diameter of steel ball 14, can make steel ball 14 expose a part at the bottom of hollow screw rod 10, can not make steel ball 14 fall out again; Pack into spring 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com