Two-color tube processing equipment

A technology for processing equipment and two-color tubes, which is applied to tubular items, other household appliances, household appliances, etc., and can solve the problems that pipes cannot be found by eye observation, pipes are opaque, and the quality of pipes varies greatly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

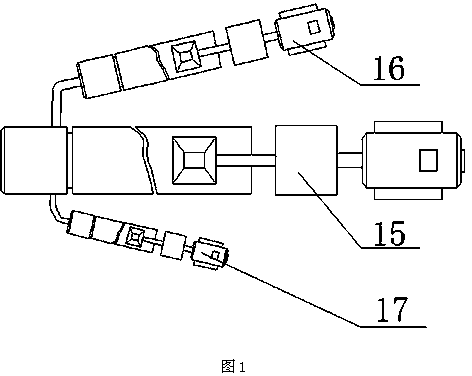

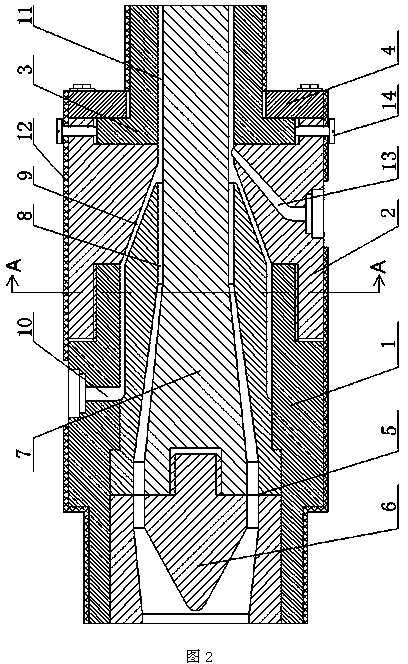

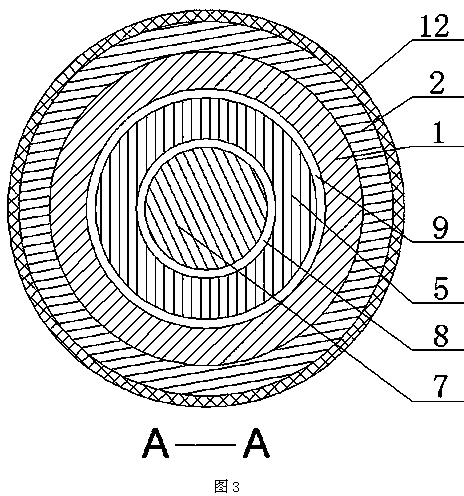

[0014] Embodiment of the present invention: a two-color tube processing equipment, such as attached Figure 1-4 As shown, the equipment includes an inner pipe extruder 15, and an outer pipe extruder 16 is provided on one side of the inner pipe extruder 15. The head end of the outer pipe extruder 16 is connected to the The outer layer glue feeding channel 10 of the head of the inner layer pipe extruder 15 is connected to the outer layer. The raw material is directly injected into the head of the inner pipe extruder 15 from its head part. The head of the inner pipe extruder 15 includes a cylindrical first part 1 of the head, the first part 1 of the head is connected with the second part 2 of the cylindrical head, and the other part of the second part 2 of the head is connected. One end face is in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com