Method of controlling power balance among multiple driving points of sealing-tape machine

A technology of power balance and control method, which is applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc. It can solve the problems of large manual labor, reduced production efficiency, and short service life of belt conveyors, and achieves the goal of manual labor. Small, overcoming the effect of large amount of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

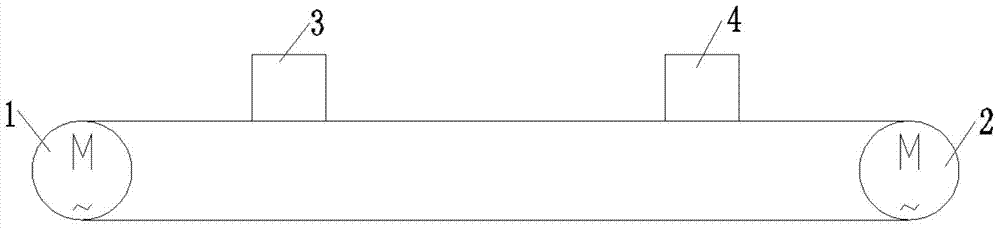

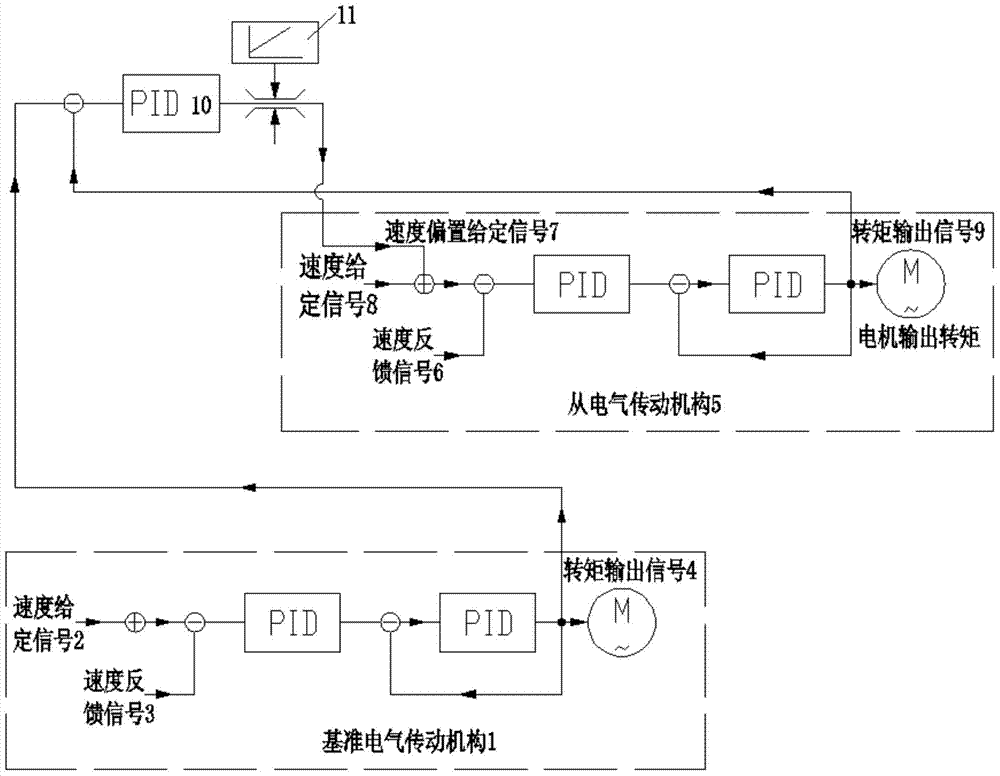

[0038] In order to solve the defects in the prior art, according to the embodiment of the present invention, such as figure 2 As shown, a control method for the power balance of multiple driving points of the tape machine is provided. During the operation process, the power balance of the tape machine at each driving point is guaranteed. The most important thing is that it can effectively solve the problem of motor stall and failure to start during the process of parking and restarting. The problem.

[0039] Technical scheme of the present invention comprises the following steps:

[0040] ⑴ Select the reference motor: select a certain motor as the reference motor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com