Tunnel excavation three-dimensional model experiment loading device

A technology of loading device and three-dimensional model, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of difficult simulation of tunnel section excavation sequence and support methods, complicated loading process, and unsatisfactory experimental results, and achieves restraint ability. Strong, high experimental efficiency and economic benefits, the effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

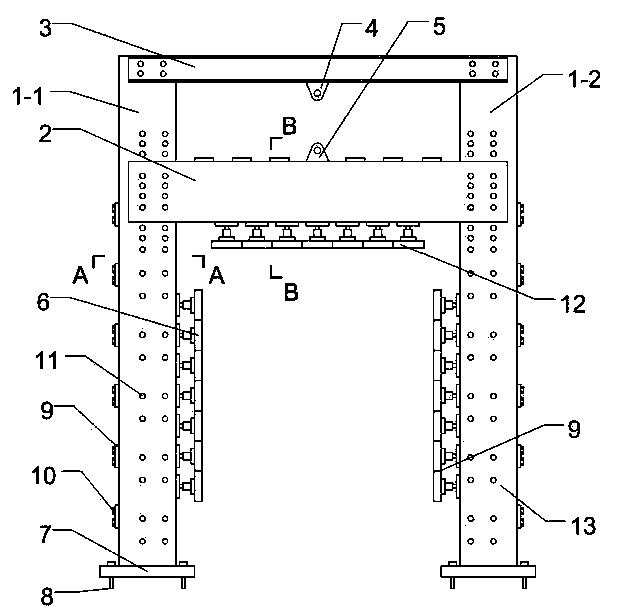

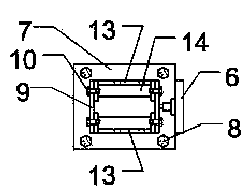

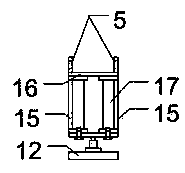

[0026] refer to Figure 1-8 , a loading device for tunnel excavation three-dimensional model experiments, comprising a loading frame, a front baffle at the front of the loading frame, and a rear baffle at the back of the loading frame, the loading frame includes a frame column, a moving beam 2 and an upper beam 3 , the moving crossbeam 2 and the upper crossbeam 3 are respectively perpendicular to the frame column, and the frame column includes a vertically arranged first frame column 1-1 and a second frame column 1-2, and the first frame column 1-1 and the second frame column A number of lateral hydraulic cylinders 6 are symmetrically installed on the inner surface of the column 1-2, and the bottoms of the first frame column 1-1 and the second frame column 1-2 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com