crystallization accelerator

A technology of crystallization and accelerator, which is applied in the direction of using additives to preserve fatty substances, fat oil/fat separation, fat oil/fat production, etc. It can solve the problems of reduced crystallization promotion effect and achieve excellent crystallization promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] [Example 1] (Preparation 1 of crystallization accelerator)

[0093] The crystallization accelerator was extracted from palm fruit according to the following procedure. split palm fruit Figure 9 Four kinds of exocarp, mesocarp (pulp), endocarp and nucleolus (testa + endosperm) shown in , weighed. Each site was heated at 100° C. for 1 hour to inactivate the lipase contained therein. In order to easily extract ingredients from each part, each part is finely divided with a mixer. Each site was dispersed in 150 ml of chloroform, and extracted for 7 hours while refluxing at 90°C. After extraction, cool at room temperature, and naturally filter (filter paper: No. 2, manufactured by Advantec) insoluble matter such as fibers, skins, and shells. After filtration, chloroform was removed by an evaporator to obtain 4 kinds of extracted oils and fats. Table 1 shows the weight of each part before extraction and the weight of the extracted oil.

[0094] [Table 1]

[0095]

...

Embodiment 2

[0106] [Example 2] (Preparation II of crystallization accelerator)

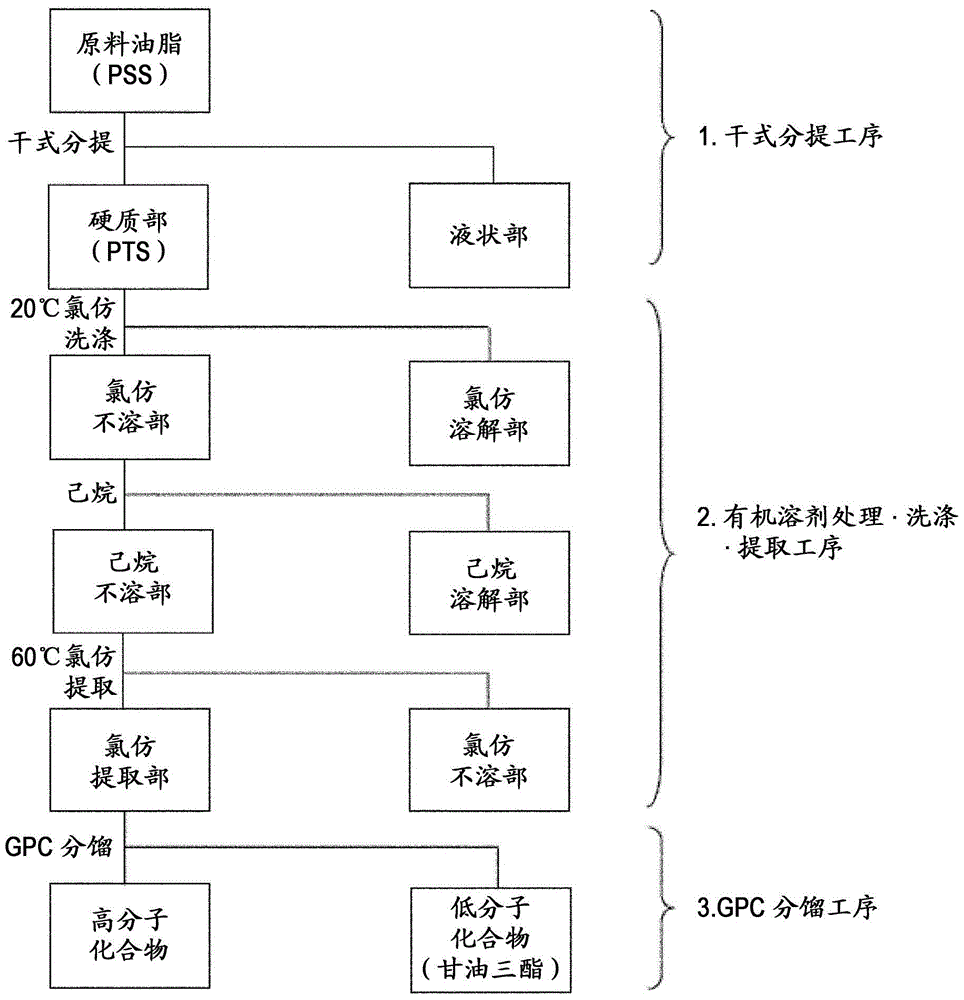

[0107] Implementation of palm oil figure 1 The dry fractionation step and the organic solvent washing and extraction step shown prepare a crystallization accelerator.

[0108] 1. Dry fractionation process

[0109] In the dry fractionation of IV12 palm superstearin (manufactured by MEWAHOLEO INDUSTRIES SDN. BHD., hereinafter referred to as PSS), a 10 kg-scale fractionation test device (Laboratory scale pilot fractionation, DeSmet Corporation) was used. First, after 9.02kg of PSS was completely dissolved at 70°C, the water temperature was slowly lowered to 60°C to precipitate crystals. During the crystallization, 2 ml of the slurry was sampled and added to a glass tube, and the SFC of the slurry was measured with the aforementioned NMR analyzer.

[0110] When the SFC of the slurry reaches 0.5%, the slurry is sent to a laboratory filter, pressurized to 15 bar for filtration, and 371 g of the hard part (PTS) a...

Embodiment 3~6

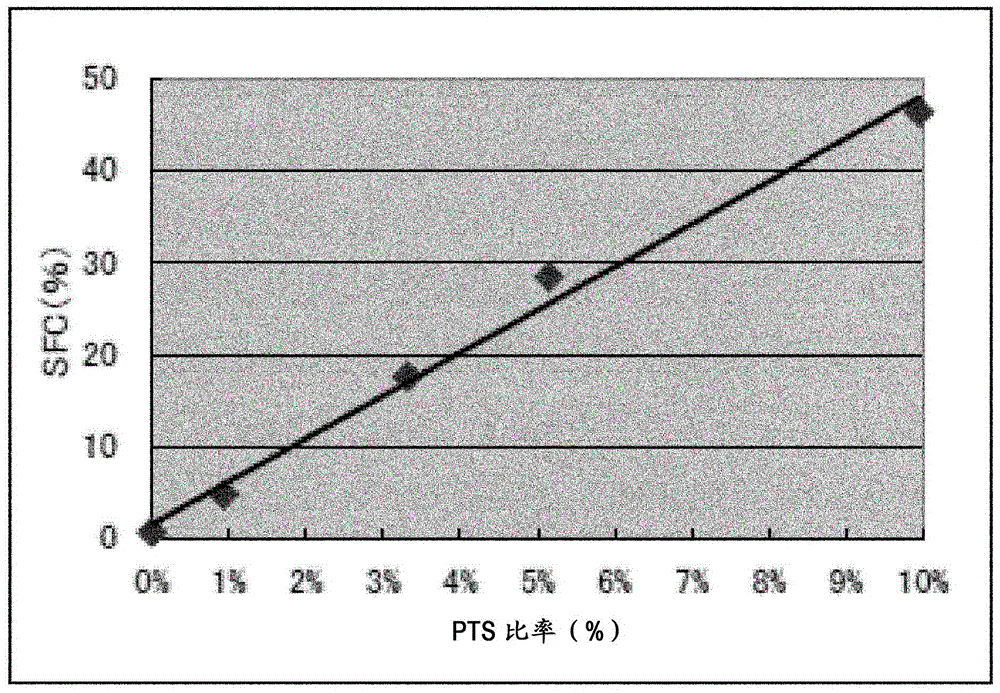

[0127] [Examples 3 to 6] (Measurement of the crystallization rate of the crystallization accelerator)

[0128] The crystallization accelerator activity (hereinafter, sometimes referred to as "activity") of the crystallization accelerator composed of PTS obtained in the dry fractionation step of Example 2 was measured. Specifically, the crystallization rate (SFC at 40° C. for 20 minutes) of an oil and fat composition in which PTS was blended with a base oil was measured. The base oil used was decolorized and deodorized PSS (manufactured by IV15MEWAHOLEO INDUSTRIES SDN.BHD.) of a different batch from the PSS used in Example 2 (hereinafter referred to as "PSS essence") in order to reduce polymer compounds. product"), and Grease B was used. The PSS refined product was adjusted so that the SFC of the oil composition (comparative example 1) in which the PSS refined product and fat B were blended in a ratio of 60:40 at 40° C. for 20 minutes was 0 to 5%. The compositions of PTS, PSS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap