Automatic green soybean husking machine

A sheller and automatic technology, applied in the fields of application, food processing, food science, etc., can solve the problems of easily injured grains, immature technology, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

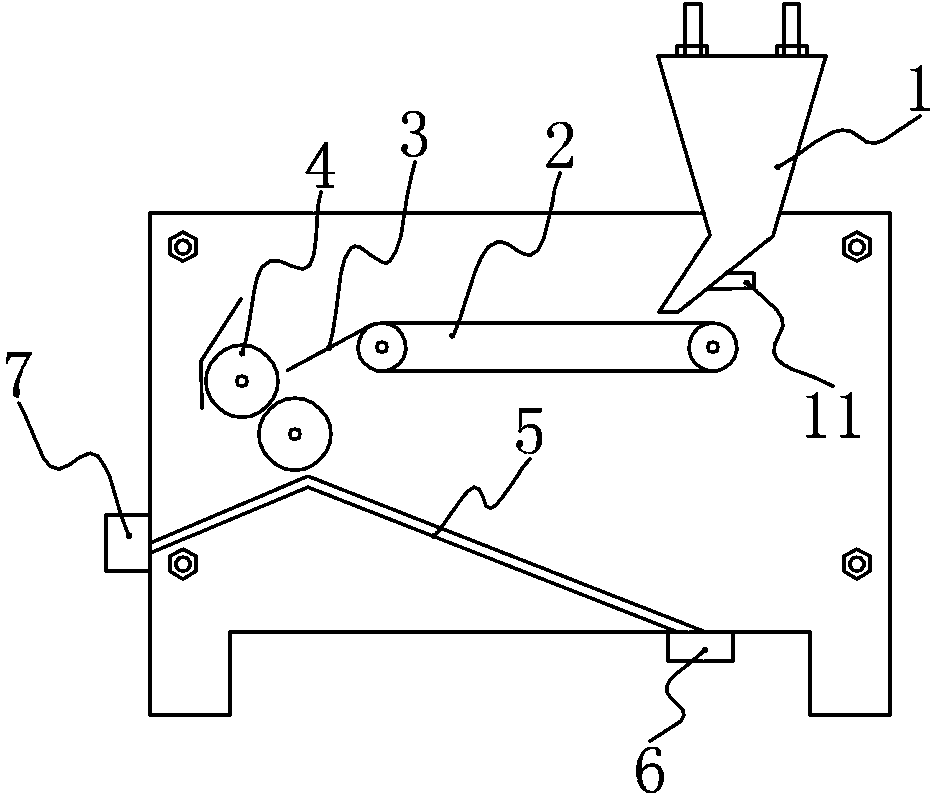

[0012] Such as figure 1 As shown, the edamame automatic peeling machine of the present invention is mainly composed of a hopper 1, a conveying mechanism 2, a material guide plate 3, a roll 4 and a bean and shell separation guide plate 5. Put the edamame pods into the hopper 1, and open and close the gate 11 below the hopper 1, so that the edamame pods are scattered and evenly dropped on the conveyor belt, and the conveyor belt sends the edamame pods to the guide plate 3, and the guide plate 3 The included angle with the horizontal plane is 60°, and slides down through the material guide plate 3 and is drawn into the roll 4. Since the two rollers 4 rotate in opposite directions, and there is a certain gap between the two rollers 4, a part of the edamame pods can be clamped and squeezed by the rollers, so that the bean grains are released from the bean shells, and the bean shells are drawn in by the rolls 4. , so that the bean grains and bean shells are separated. In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com