Universal supporting and fixing device for ball type parts

A technology for fixing devices and parts, applied in the directions of packaging, transportation and packaging, external frames, etc., can solve the problems of increasing use and production costs, and cannot be used universally, and achieves strong adaptability and practicability, and is convenient for large-scale production and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

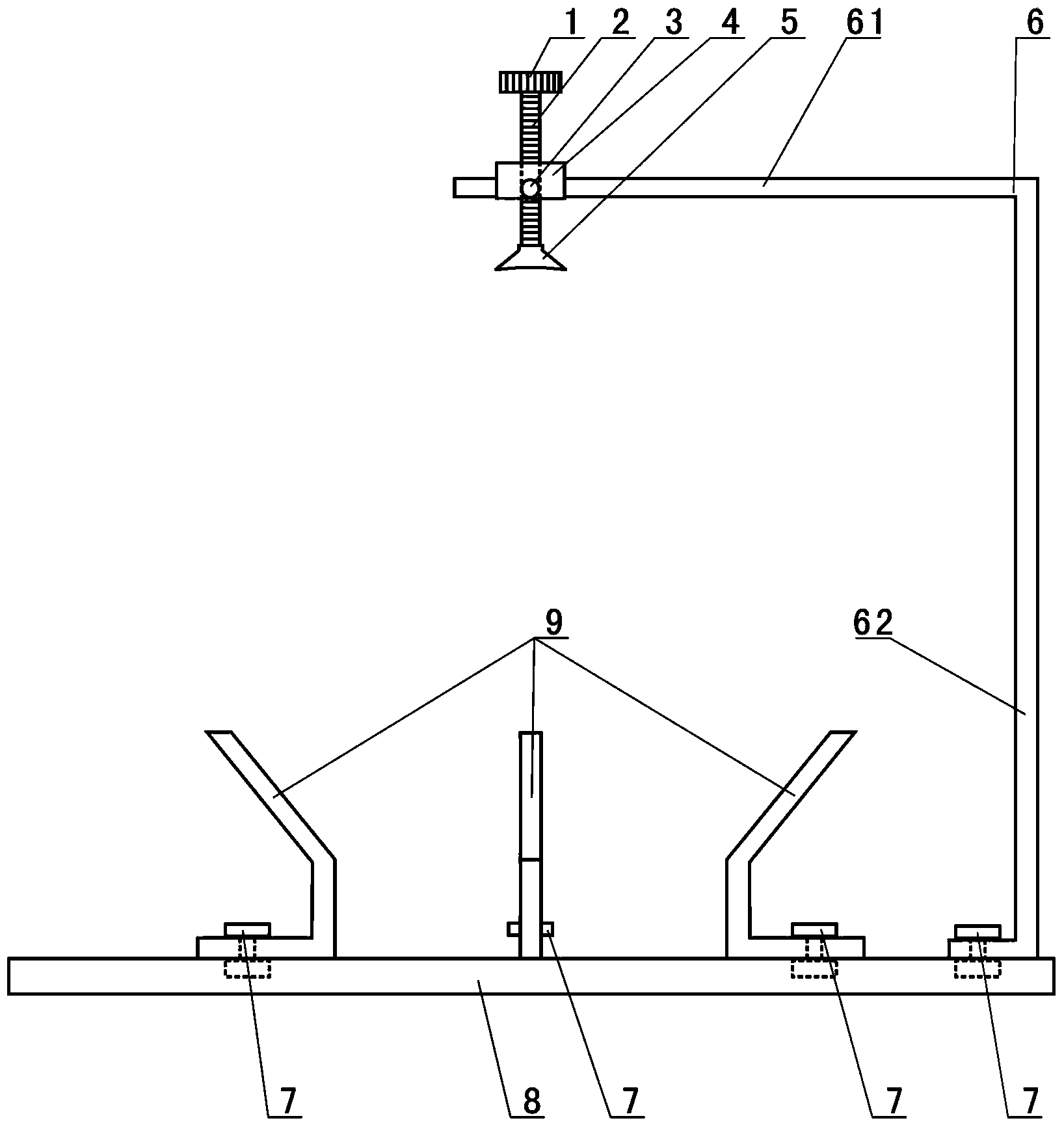

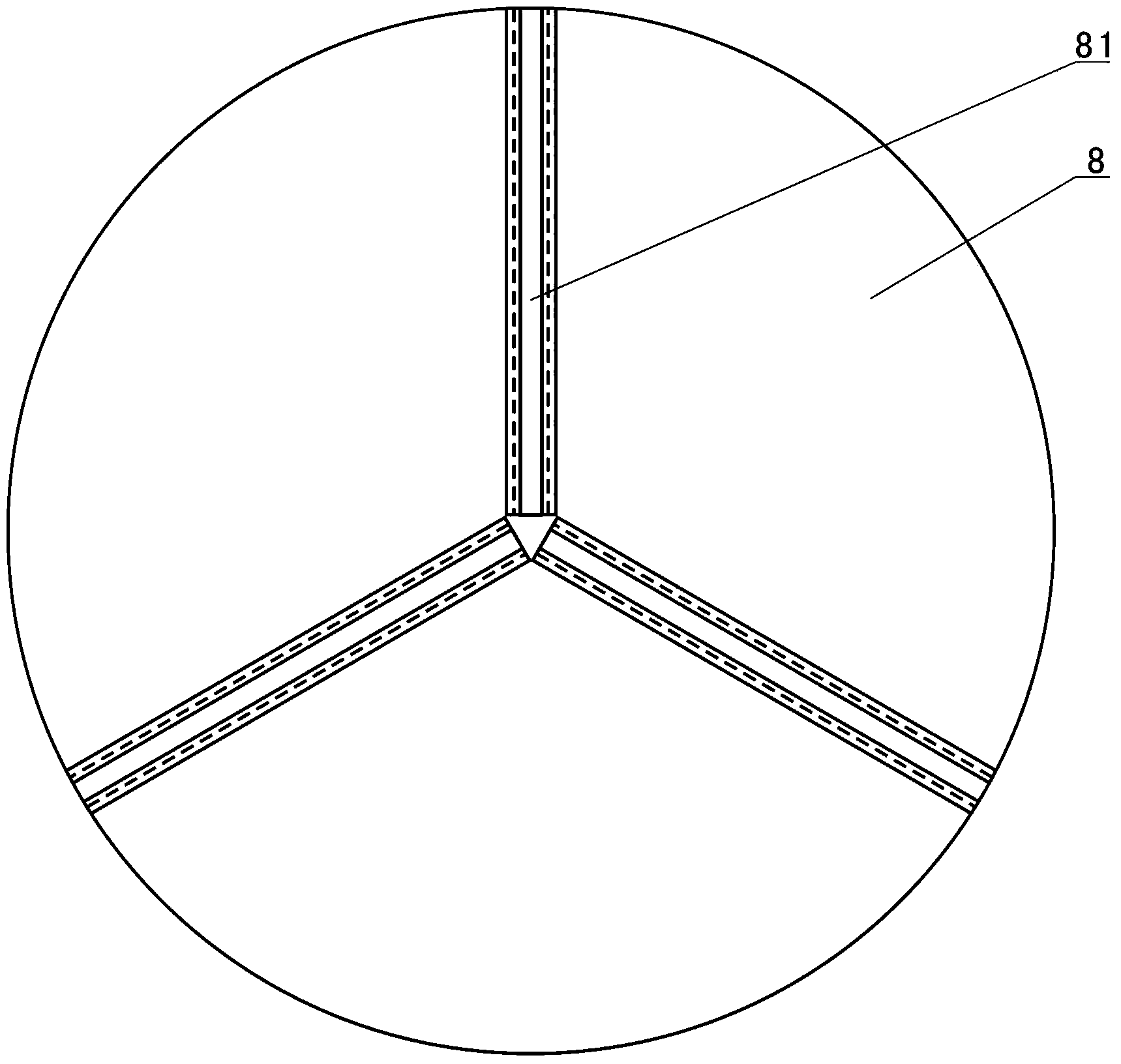

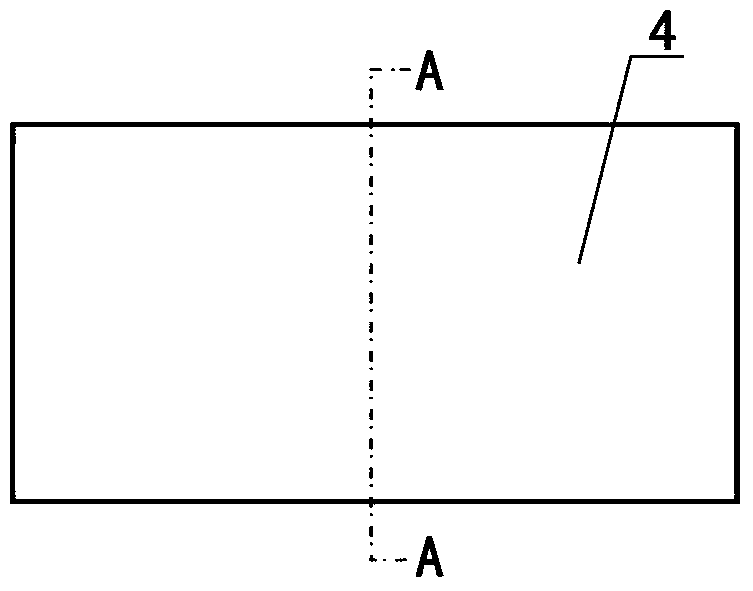

[0022] like Figure 1-Figure 5 As shown, the general support and fixing device for ball parts of the present invention includes a base 8, a lower support 9, an upper support 6, a connector 4, a pressing bar 2 and a briquetting block 5, and the upper surface of the base 8 is provided with three radial The cross-section is a "T"-shaped strip chute 81, the central axes of the three strip chute 81 intersect at a center of a circle (a virtual center) and are evenly distributed around the center of the circle, and the upper parts of the three lower supports 9 have an inclined surface , the slope faces the center surrounded by a plurality of lower supports 9 (being a virtual center) and the slope approaches the edge of the base 8 gradually from bottom to top, and the lower section of the lower support 9 is "L" shaped, and the "L" The horizontal part of the shape is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com