Tunnel face blasthole charge device

A tunnel face and tunnel technology, which is applied to the field of blasthole charging devices for tunnel face faces, can solve problems such as few equipment, and achieve the effects of improving controlled blasting effect, ensuring charging coefficient, strong adaptability and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

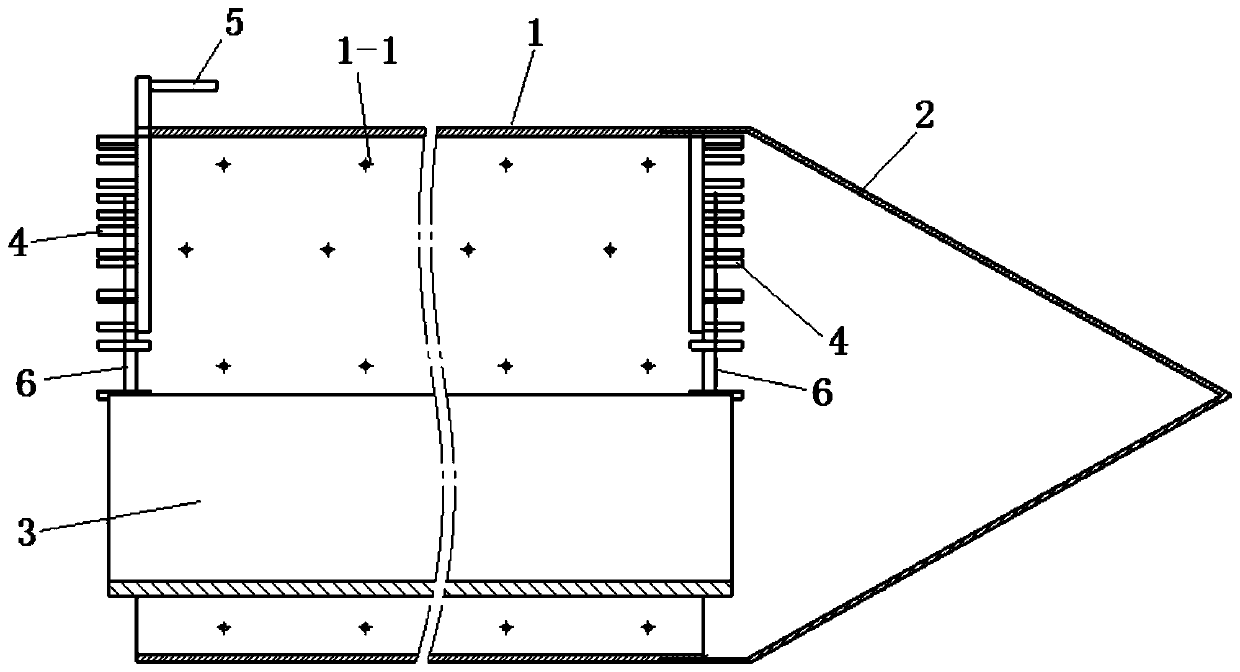

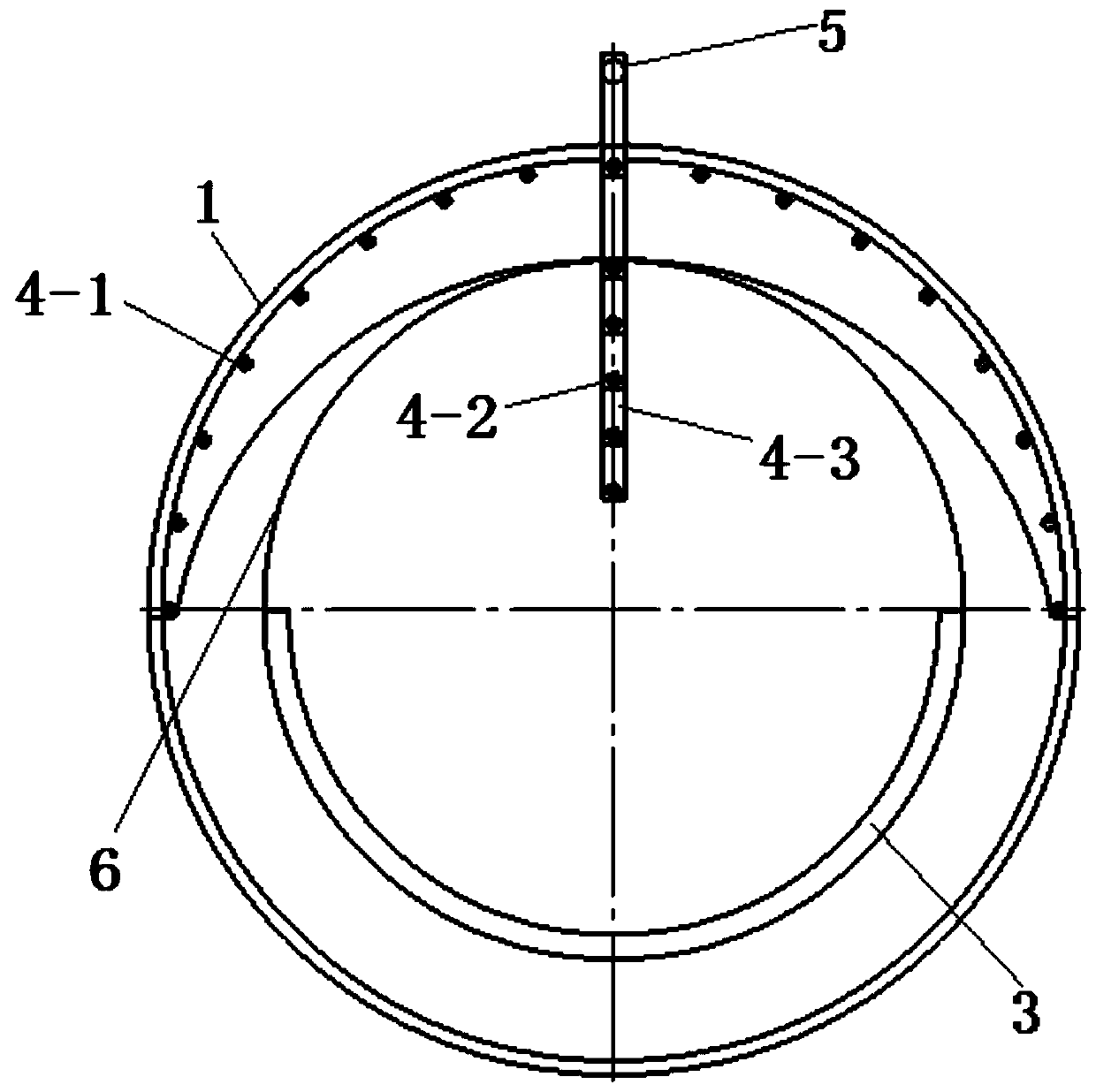

[0021] Such as figure 1 and figure 2 As shown: the charge device for the tunnel face blast hole includes a charge cartridge 1, a guide head 2, a cartridge gasket 3, a positioning piece 5, two fixing rings 6 and two adjustment structures 4; the two adjustment structures 4 are respectively located at At both ends of the cartridge 1, the adjustment structure 4 includes a jacking rod 4-3, a plurality of fixed heads 4-1 and a plurality of jacking heads 4-2, and each fixed head 4-1 is along the top half of the cartridge 1. Arranged at intervals in the circumferential direction and connected to the cartridge 1, the jacking rods 4-3 are set up and down and the upper end is connected to the upper end of the cartridge 1, and the jacking heads 4-2 are arranged at intervals in the up and down direction and connected to the jacking rods 4-3 Connection; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com