A carbon-silicon composite material and its preparation method and preparation system

A composite material and preparation system technology, applied in the field of carbon-silicon composite material and its preparation, can solve the problems of narrow application range, short action time, poor improvement effect, etc., and achieve lower production cost, easy large-scale production, good affinity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

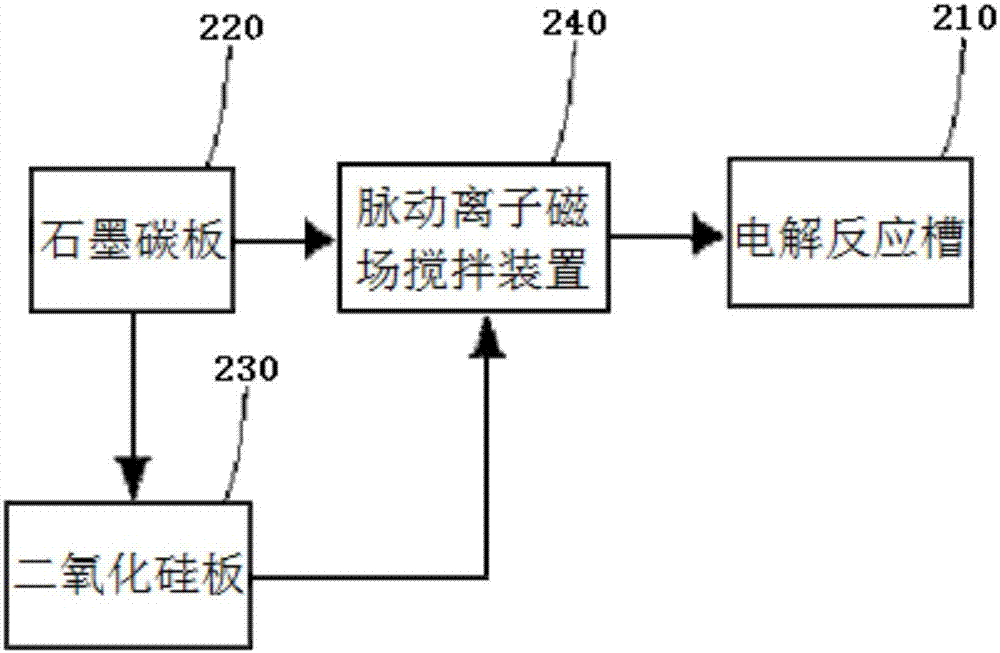

[0029] refer to figure 1 , the specific preparation method of the carbon-silicon composite material is as follows:

[0030] 1) First select graphite carbon with a purity of 99.9%, and use a calcined static pressure process to make a graphite carbon plate 220. The calcined static pressure process can achieve the best value for the purity and hardness of graphite, thereby producing the smallest particle size and the highest purity Highest carbon nanoparticle;

[0031] 2) Select silicon dioxide powder with a particle size range of 1-50nm to make a silicon dioxide plate 230;

[0032] 3) Place the graphite carbon plate 220 and the silicon dioxide plate 230 in the electrolytic reaction tank 210, connect the pulsating ion magnetic field stirring device 240 with a copper wire in series, and after adding pure water, feed the pulsating direct current into the electrolytic reaction tank 210 , to control its pulsating DC current 40A, voltage 12V;

[0033] 4) After the pH value in the e...

Embodiment 2

[0035] The carbon powder produced according to the preparation method of Example 1 is sent to Shanghai Institute of Metrology and Testing Technology, East China National Metrology and Testing Center, and China Shanghai Testing Center for testing as a sample. The scanning electron microscope used is Nova NanoSEM 450. The X-ray energy spectrometer is 51-XMX1154, and the sample composition test results of the carbon powder are expressed as follows in terms of mass percentage: C, 95.3%, O, 3.4%, P, 0.4%, S, 0.2%, Cl, 0.2%, K , 0.6%.

Embodiment 3

[0037] The carbon solution produced according to the preparation method of Example 1 is sent to Shanghai Institute of Metrology and Testing Technology, East China National Metrology and Testing Center, and China Shanghai Testing Center for testing as a sample. The scanning electron microscope used is Nova NanoSEM 450. The X-ray energy spectrometer is 51-XMX1154, and the chemical composition of the carbon solution is represented by mass percent: C, 41.0%, O, 51.8%, Na, 2.4%, Mg, 1.1%, Si, 0.3%, S, 1.0 %, Cl, 1.4%, Ca, 1.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com