A construction method for a tunnel constructed from two halves of rectangular pipe joints with outer chamfers

A construction method and technology of rectangular pipes, which are used in tunnels, earth-moving drilling, mining equipment, etc., can solve the problem that the circular shield section has a high utilization rate of rectangular sections, cannot fully meet the needs of use, and the jacking distance cannot be too long. and other problems, to achieve the effect of high section utilization rate, long advancing distance, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

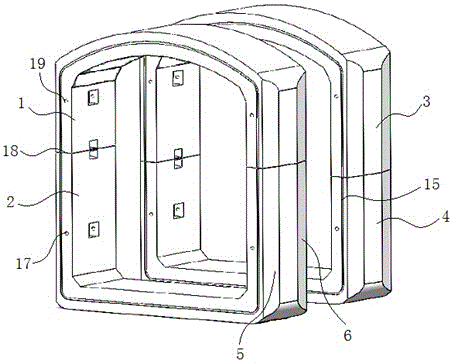

[0023] Such as figure 1 As shown, a tunnel is composed of two halves of rectangular pipe sections with outer chamfers. One of the two halves of rectangular pipe sections is connected by a small upper pipe section 1 and a large lower pipe section 2 to form a ring of rectangular pipe sections. One is that the large upper pipe joint 3 and the small lower pipe joint 4 are connected to form a ring of rectangular pipe joints; there are first chamfers 5 and second chamfers 6 on both sides of each ring of rectangular pipe joints. A plurality of rectangular pipe joints arranged alternately by these two kinds of pipe joints are connected together to form a tunnel. The top of the tunnel is arched, and a sealing ring 15 is arranged between two adjacent rings of rectangular pipe joints.

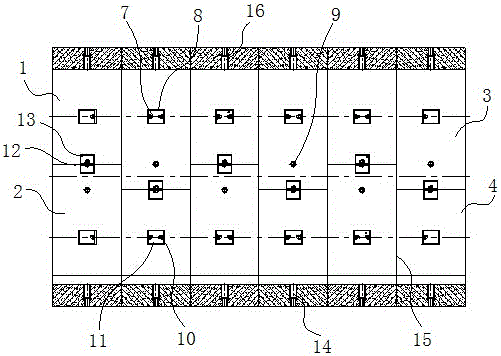

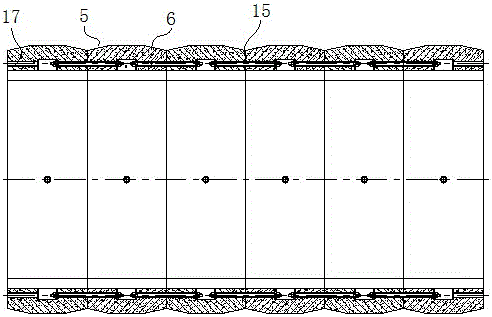

[0024] Such as figure 2 with image 3 As shown, the adjacent small upper pipe joint 1 and the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com