Preparation method of visible patterns of outdoor glasses

A pattern and glasses technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of inapplicability, inability to achieve sporty and beautiful young people to express individualized thinking, and achieve safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

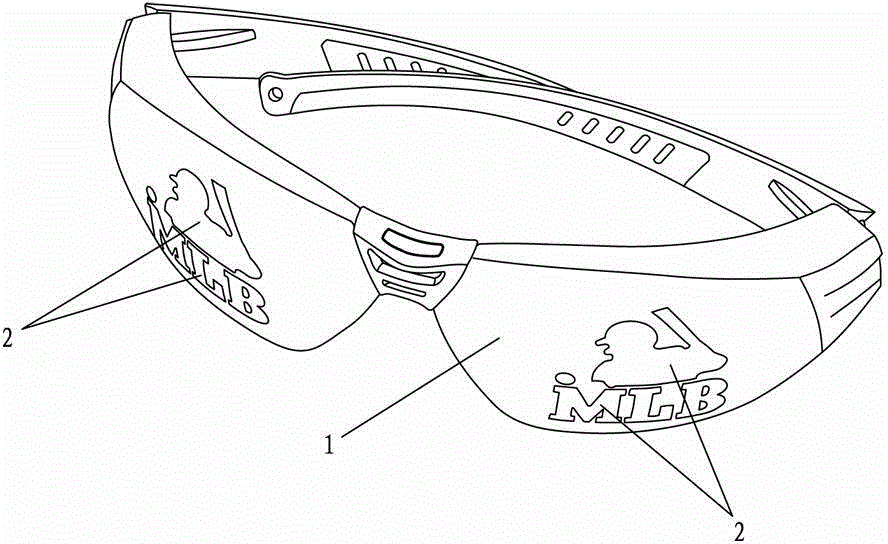

[0017] Example: see figure 1 , a kind of preparation method of outdoor glasses visible pattern, comprises the steps:

[0018] (1) Make a pattern, and print ink on the lens substrate to form a pattern;

[0019] (2) Electroplating, the surface of the lens substrate is electroplated to form a metal electroplating layer and cover the ink pattern in step (1), that is, the lens 1 with a metal electroplating layer is formed. This process is performed after the printing ink in step (1) is dry. Operation;

[0020] (3) Adhere the electroplating layer and the lens substrate with adhesive tape, pull up the tape to tear off the ink pattern and the corresponding metal electroplating layer at the same time, and the remaining metal electroplating part and the ink printing area of the lens substrate are set against each other to form a lens Visual patterns of 2.

[0021] The lens base material in the present invention is a PC lens. The color of the lens substrate used in the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com