Floor structure for outdoor basketball sport

A floor and basketball technology, which is applied to building structures, floors, buildings, etc., can solve the problems of non-recyclable, short service life, human body and environment damage, etc., and achieve the effect of prolonging service life, long service life and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

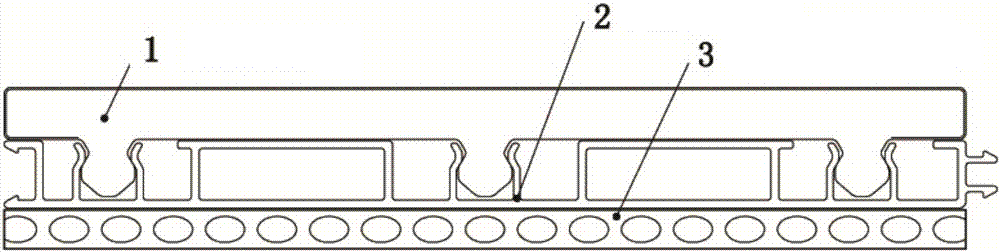

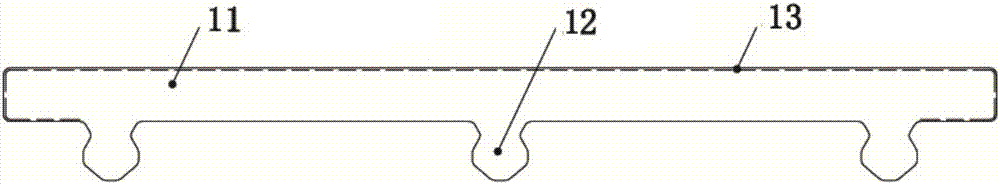

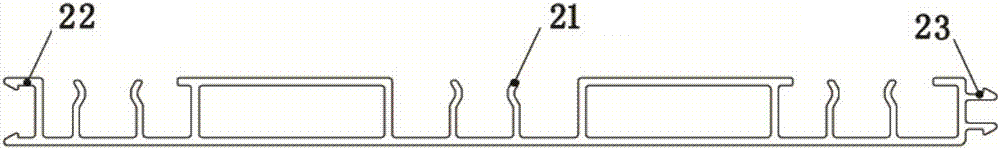

[0029] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the floor structure used for outdoor basketball of the present invention, including: a composite plastic layer 1, a metal skeleton layer 2 and a closed-cell foam buffer layer 3, the composite plastic layer 1 is located at the uppermost layer, and the metal skeleton Layer 2 is connected to the lower side of the composite plastic layer, the closed-cell foam buffer layer 3 is connected to the lower side of the metal skeleton layer 2, and the surface Shore hardness of the composite plastic layer 1 is greater than 65. The outdoor basketball floor structure of the present invention has the comfort, safety and mobility of an indoor basketba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com