Organic microparticles

A technology of organic particles and particle shapes, applied in other chemical processes, coatings, chemical instruments and methods, etc., can solve the problems of water repellency reduction and achieve high sliding speed and excellent sliding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0434] Hereinafter, although an Example is given and this invention is demonstrated in detail, this invention is not limited to these Examples.

[0435] Hereinafter, a part or % or a ratio means a weight part or a weight % or a weight ratio unless otherwise specified.

[0436] The sequence of tests is as follows.

[0437] [Number average molecular weight (Mn), weight average molecular weight (Mw), molecular weight distribution (Mw / Mn)]

[0438] Number average molecular weight (Mn), weight average molecular weight (Mw), and molecular weight distribution (Mw / Mn) were determined by gel permeation chromatography (GPC). In GPC, tetrahydrofuran was used as a developing solution, KF-606M, KF-601, and KF-800D manufactured by Shodex were used as columns, and molecular weights and the like were calculated in terms of polystyrene.

[0439] [Measurement of Thermal Properties by Differential Scanning Calorimetry (DSC)]

[0440] The melting points of the polymers were calculated by Diffe...

Synthetic example L1~L5

[0445] A chloroform solution of the polymer (solid content concentration: 1.0%) was spin-coated on a silicon wafer substrate (research high-purity silicon wafer AS ONE2-960-55), and heated at 80° C. for 15 minutes to form a coating film. 2 μL of water was dropped on the coating film, and the static contact angle after dropping for 1 second was measured with a fully automatic contact angle meter (Drop Master 701 manufactured by Kyowa Interface Science).

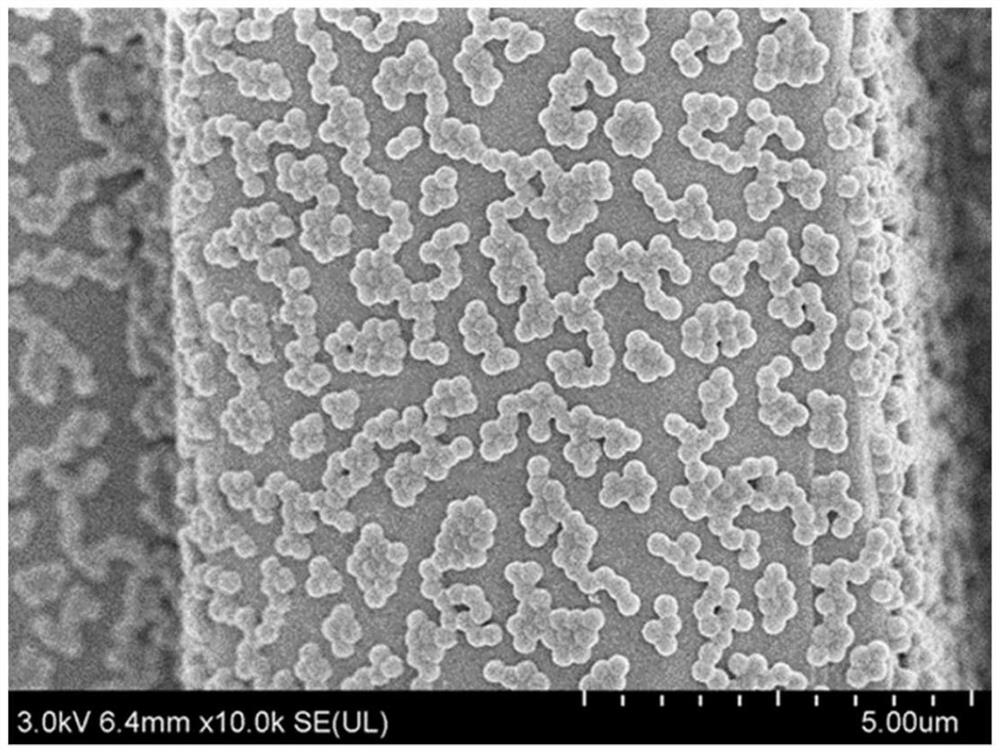

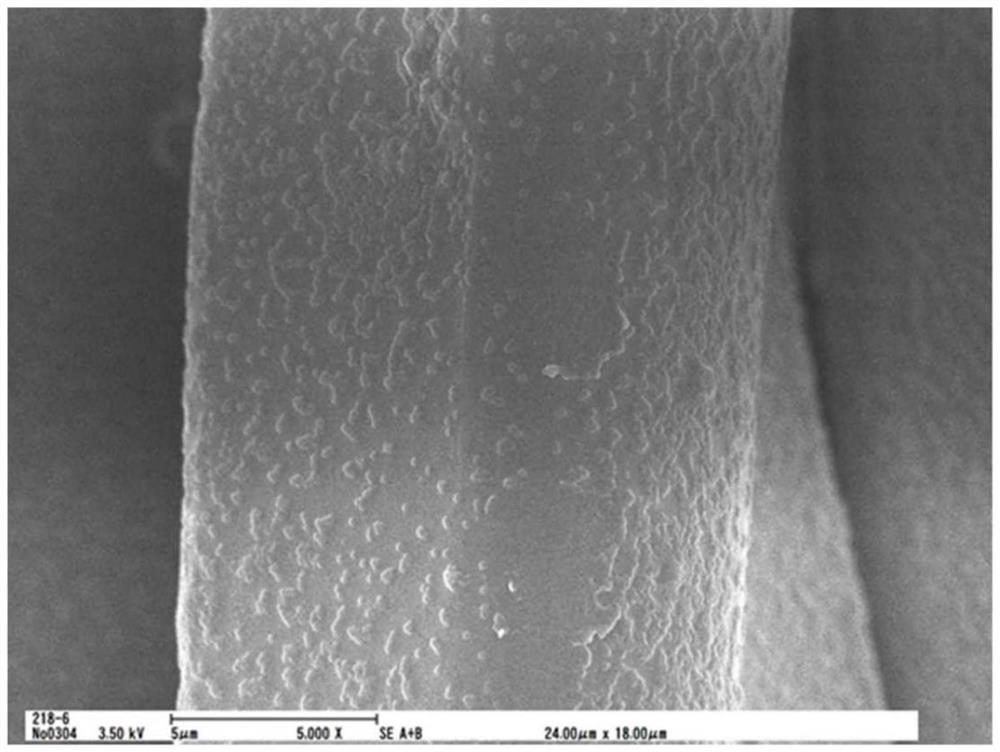

[0446] (organic particles)

[0447] The contact angle of the organic microparticles is measured as follows: drop-coat the aqueous dispersion of the organic microparticles on a glass substrate (made of soda-lime glass on slide glass), heat at 150° C. for 3 minutes, and prepare a substrate with the organic microparticles attached thereto. 2 μL of water was dropped on the glass substrate containing the organic fine particles, and the static contact angle after dropping for 1 second was measured with a fully automatic contact angl...

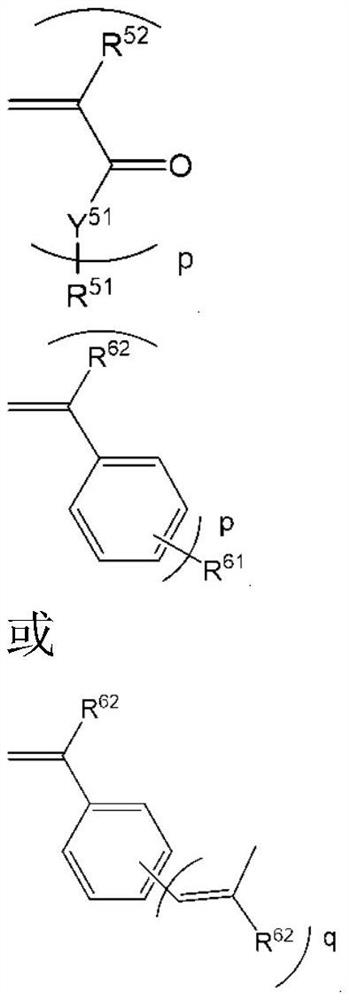

Synthetic example 2~44

[0522]Except having used the monomer shown in Table 1 as a monomer, the procedure similar to the synthesis example 1 was repeated. The results are shown in Table 1. In Synthesis Examples 25 to 28, in addition to the monomers shown in the table, a cationic emulsifier (lauryltrimethylammonium chloride) was added in a predetermined amount shown in the table with respect to the total amount of monomers, followed by polymerization. In Synthesis Example 29, in addition to the monomers shown in the table, 0.5% of a cationic emulsifier (lauryltrimethylammonium chloride) and polyethylene glycol monooleyl ether were added to the total amount of monomers. polymerization. The aqueous dispersion of the organic microparticles synthesized in Synthesis Example 13 was cast onto a glass substrate, air-dried, and then left to stand in an environment of -30° C. for 2 days. Then, when the substrate was taken out in an environment of 25° C., frost adhered to the glass, but no frost was observed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com