Sequential relays capable of controlling multiple loads

A relay and multi-load technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of single control, single function, and obsolete structure, and achieve the effect of reducing production costs and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

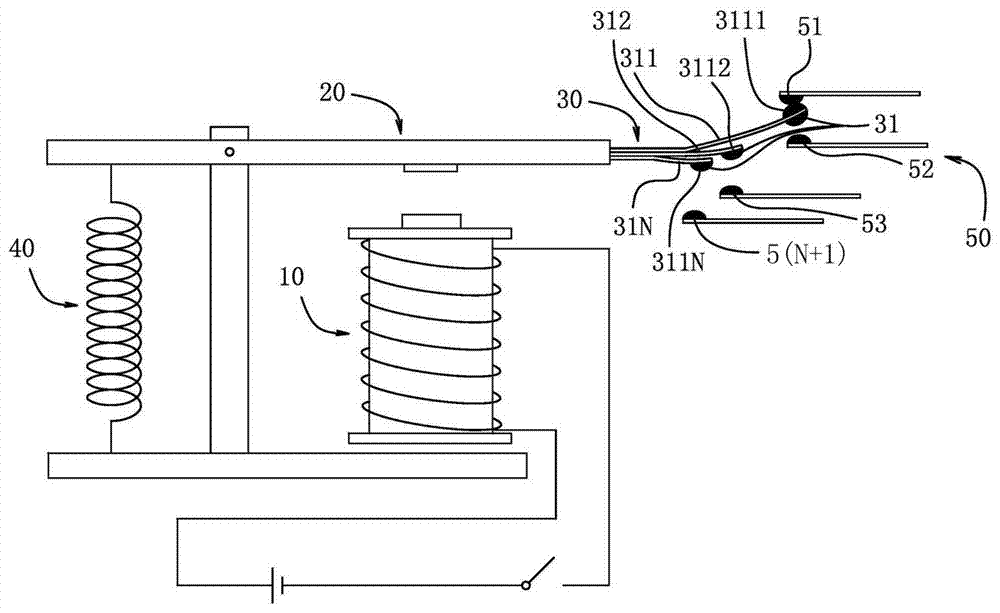

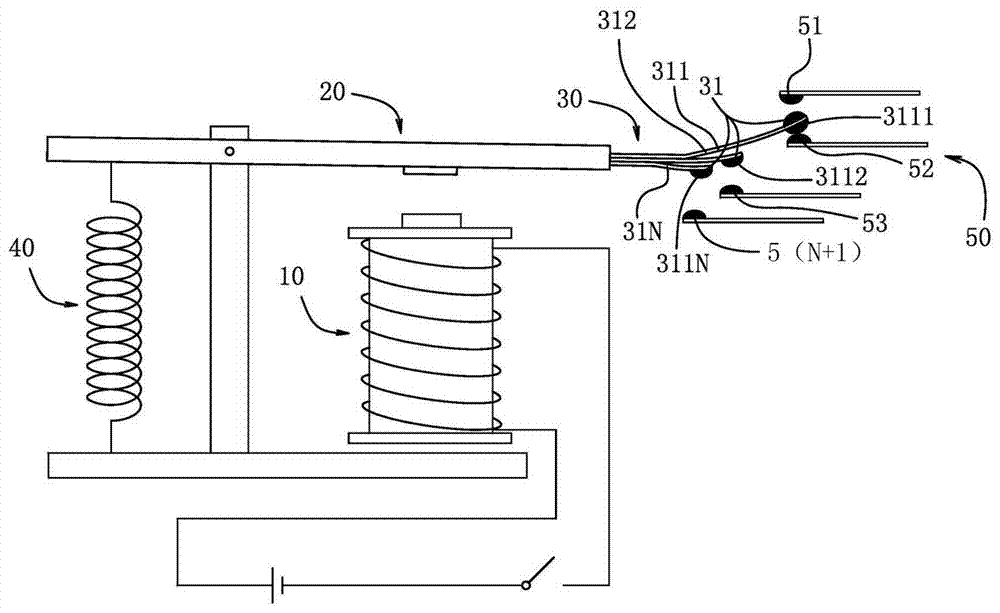

[0018] refer to Figure 1 to Figure 6 , the multi-load controllable sequential relay of the present invention includes an electromagnet 10, an armature 20, a spring 40, a movable contact 31 and a static contact 50, and each component forms an electromagnetic relay.

[0019] Such as Figure 1 ~ Figure 3 As shown, the gist of the present invention is that a plurality of conductive elastic pieces with movable contacts and static contacts corresponding to the movable contacts are arranged at one end of the armature 20 . The plurality of conductive elastic pieces 30 include a first conductive elastic piece 311 to an Nth conductive elastic piece 31N, and the number of conductive elastic pieces is determined according to the load to be controlled by the timing relay. exist Figure 1 ~ Figure 3 In the illustrated embodiment, a first conductive elastic piece 311 and a second conductive elastic piece 312 are provided at one end of the armature 20, and the first conductive elastic piec...

Embodiment 2

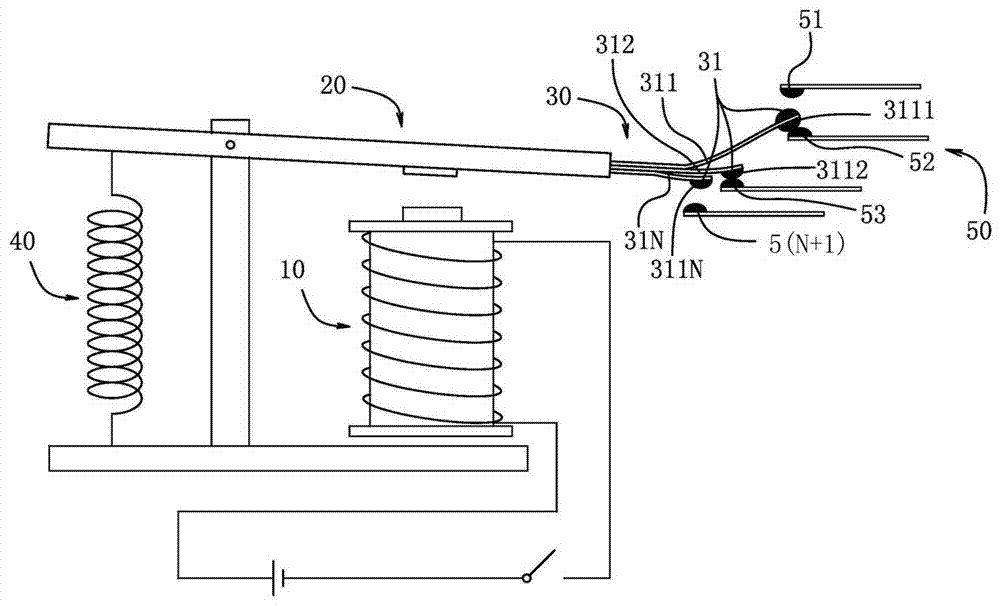

[0022] Its basic structure is the same as that of Embodiment 1, the difference is that the plurality of conductive elastic pieces 30 are dislocated in the horizontal direction, one end of which is fixedly connected to the armature 20, and the other end extends forward. Such as Figure 4 ~ Figure 6 As shown, the plurality of conductive elastic pieces 30 include the first conductive elastic piece 311 to the Nth conductive elastic piece 31N, and the plurality of conductive elastic pieces 30 are arranged at the front end of the armature 20 in a horizontal direction, that is, the plurality of conductive elastic pieces 30 are horizontally The directions are dislocated at a certain angle, and the lengths of the multiple conductive elastic pieces 30 can be the same or different. The plurality of static contacts 50 are respectively arranged below the corresponding movable contacts 31 of the respective conductive elastic pieces. The working process of the sequential relay is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com