A self-inflating silicone airbag air cushion

A self-inflating, silica gel technology, applied in the field of air cushions, can solve the problems of product loss of function, failure to reach consumers, slow leakage of airbags, etc., and achieve the effect of simple structure, long service life, and reduced inflatable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

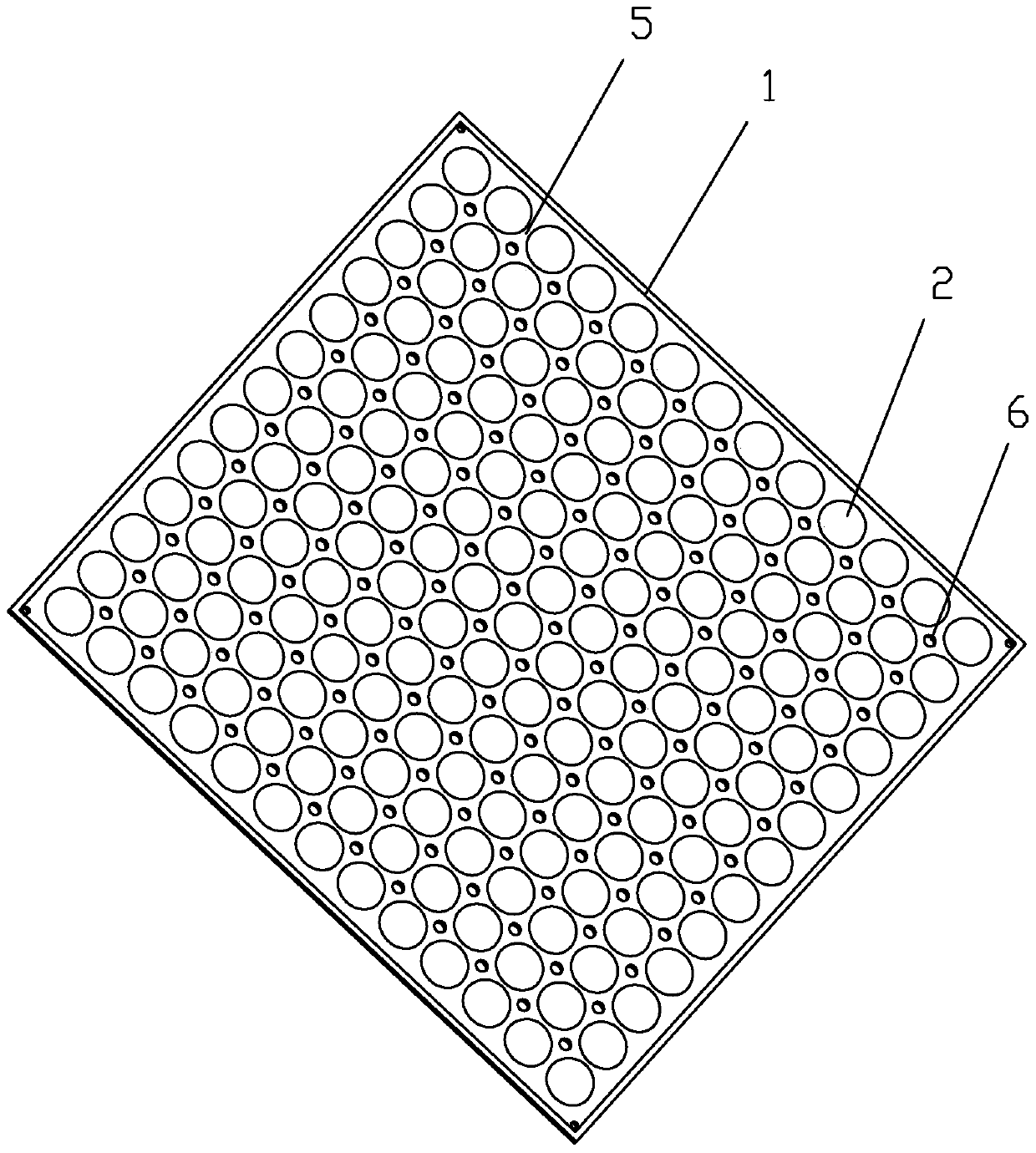

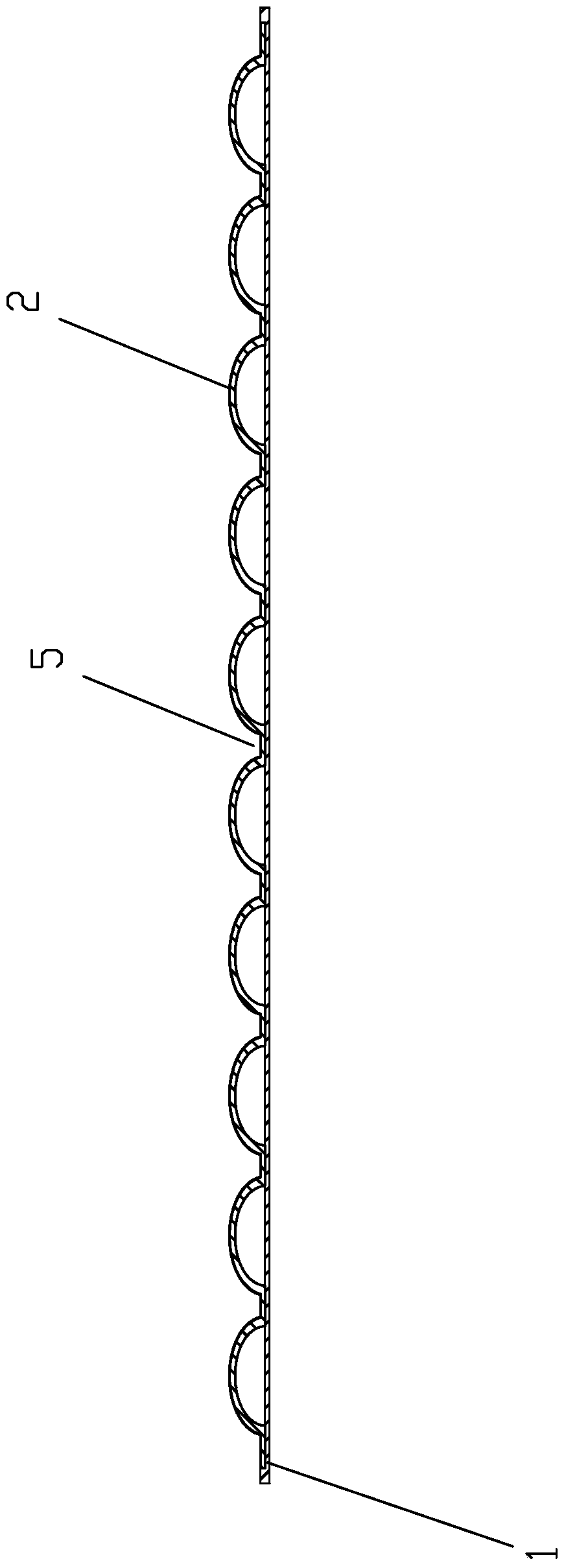

[0035] Such as Figure 1 to Figure 2As shown, a self-inflating silicone airbag air cushion includes a silicone substrate 1, and one side of the substrate 1 is provided with a number of mutually independent and raised upper silicone airbags 2, and the wall thickness of the upper silicone airbag 2 is 0.3mm~ 2 mm, a height of 3 mm to 50 mm, and a volume of 100 cubic millimeters to 300,000 cubic millimeters. The hardness of the self-inflating silicone airbag air cushion is 40 to 70 degrees Shore hardness. The substrate 1 is provided with a through hole 6 between the upper silicone airbags 2. When the self-inflatable silicone airbag air cushion is placed on the ground, the air between the air cushion and the ground can be quickly discharged from the through hole 6, so that the air cushion It is not easy to slide on the ground, especially when used in the bathroom, water enters between the air cushion and the floor through the through hole 6, squeezes out the air between the air cus...

Embodiment 2

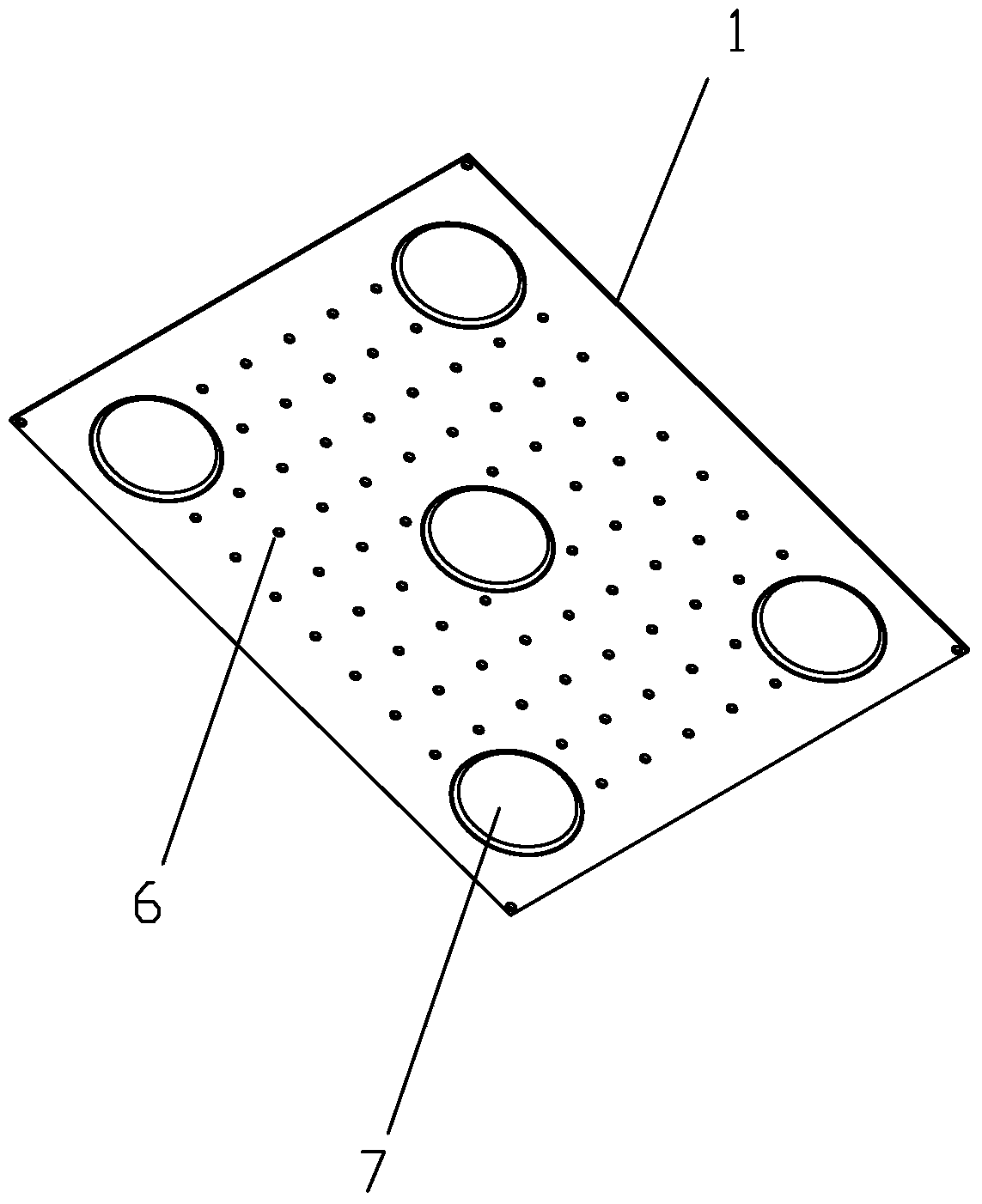

[0037] Such as Figure 3 to Figure 4 As shown, the difference between embodiment 2 and embodiment 1 is:

[0038] The base plate 1 is provided with a suction cup 7 for absorbing the self-inflating silicone airbag air cushion onto the supporting surface. When in use, the air cushion is pressed against the support surface such as the ground to discharge the air in the suction cup 7. Due to the elastic recovery of the air cushion, a vacuum is formed in the suction cup 7, so that the air cushion is firmly connected with the support surface such as the ground and is not easy to move.

Embodiment 3

[0040] Such as Figure 5 to Figure 7 As shown, the difference between embodiment 3 and embodiment 1 is:

[0041] The other side of the substrate 1 is provided with a plurality of lower silicone airbags 3 that are independent of each other and protrude and communicate with the upper silicone airbag 2. The wall thickness of the lower silicone airbags 3 is 0.3 mm to 2 mm, and the height is 3 mm to 50 mm. , the volume is 100 cubic millimeters to 300000 cubic millimeters, the upper layer airflow channel 5 is formed between each upper layer silicone airbag 2, and the lower layer airflow channel 4 communicating with the upper layer airflow channel 5 through the through hole 6 is formed between each lower layer silicone airbag 3, so Described lower layer silica gel air bag 3 is hemisphere, or other shapes such as cube. When the human body is just pressed onto the air cushion, both the upper silicone airbag 2 and the lower silicone airbag 3 are compressed and deformed. During the defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com