A kind of soft state billet cutting method and its cutting device

A cutting device and blank technology, applied in the field of mechanical design and manufacturing, cutting machine design and manufacturing, can solve the problems of not being able to meet the requirements of the cross-section of the catalyst, not being able to guarantee micro-cracking, affecting production efficiency, etc., to achieve control of visible cracks And hidden cracks, meet the cutting requirements of small deformation, improve the effect of effective service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

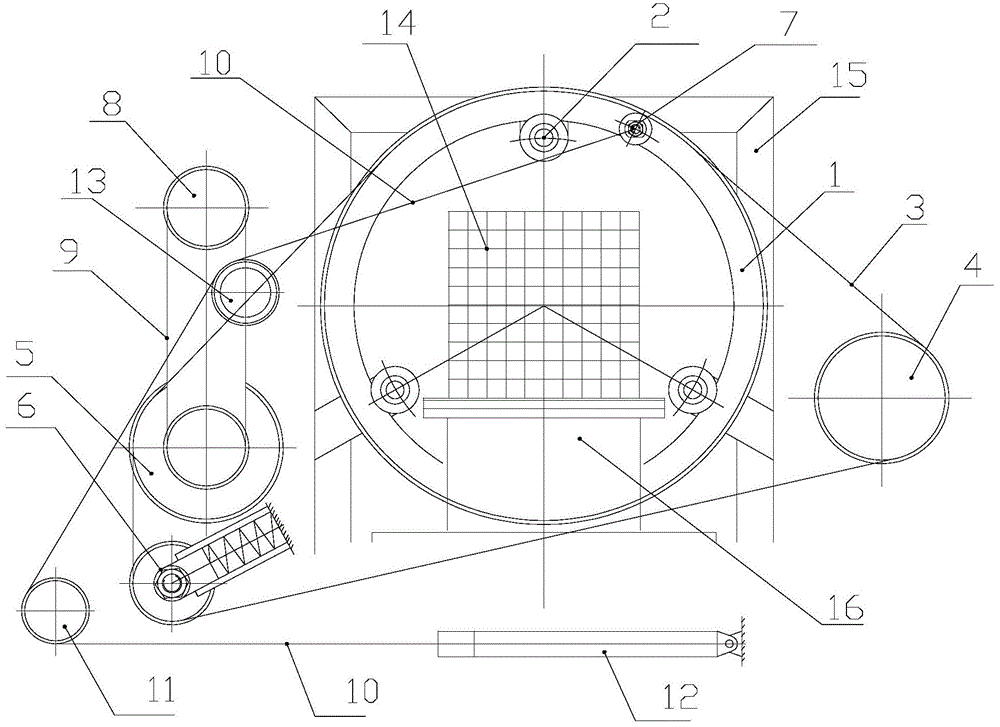

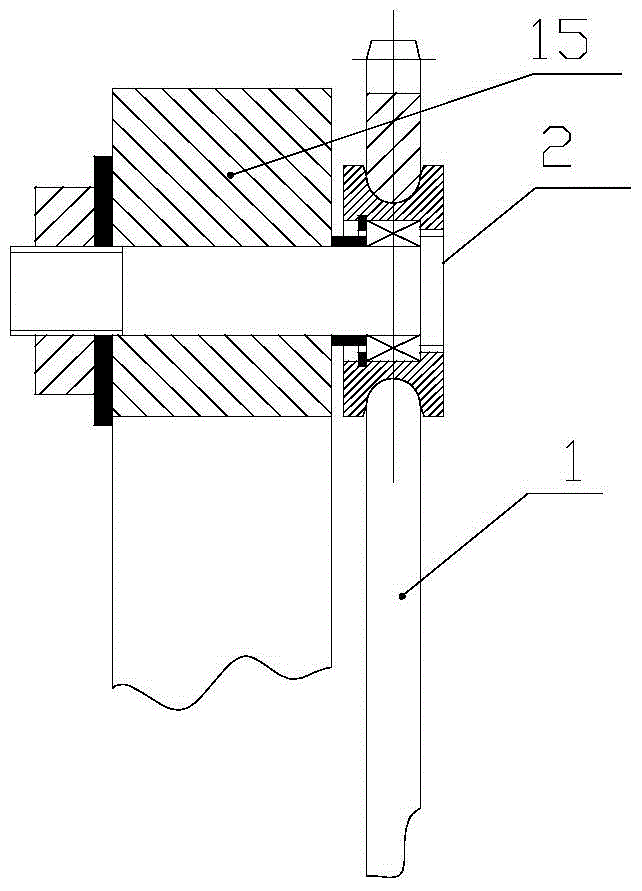

[0032] combine Figure 1 to Figure 8 .

[0033] The soft blank cutting device, as shown in the figure, includes a blank bracket 16 and a wire cutter 10; it also includes a wire cutter driving device, and the wire cutter driving device is used to drive the soft blank 14 on the wire cutter 10 to cut the blank bracket 16, When cutting, keep the steel wire knife 10 and the horizontal plane at an inclination greater than zero, and drive the steel wire knife 10 to move vertically downward and move along the tension direction of the steel wire knife 10; it also includes a steel wire constant tension device, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com