Diesel engine particulate filter regeneration system and methods

A technology of engine system and diesel engine, which is applied in the direction of engine components, combustion engine, engine control, etc., can solve problems such as exhaust restriction, and achieve the effects of improved control, improved torque control and engine emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

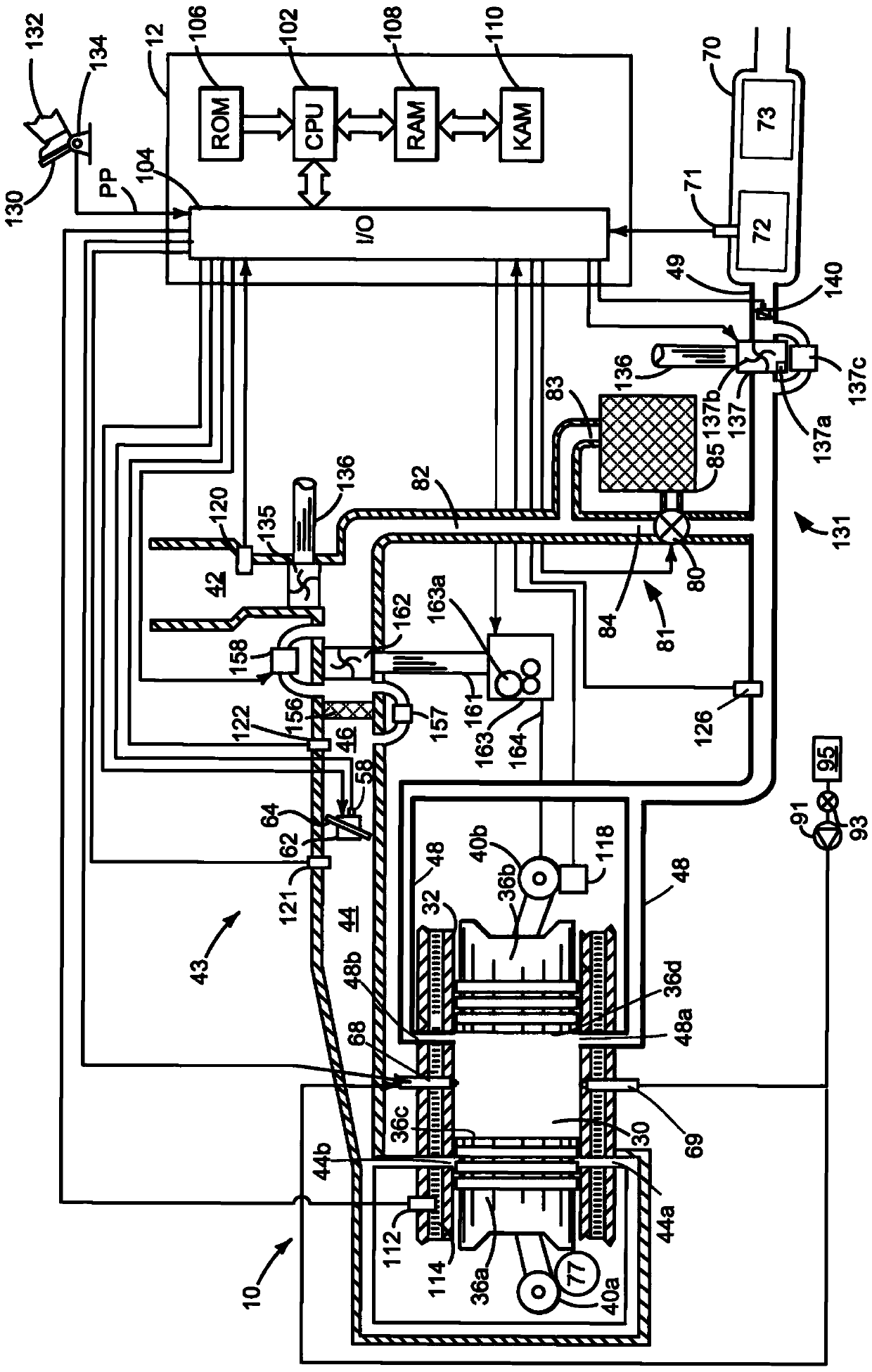

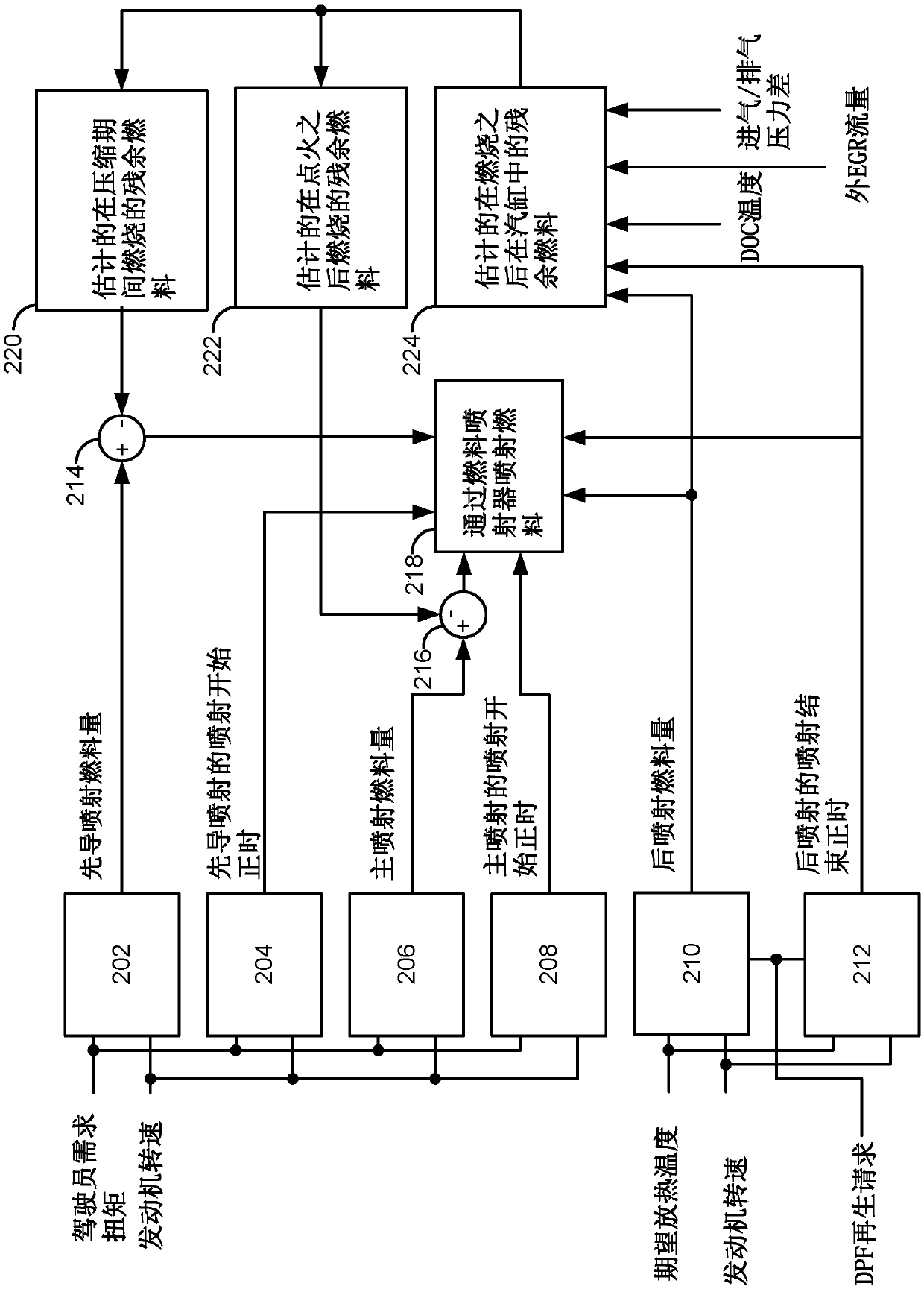

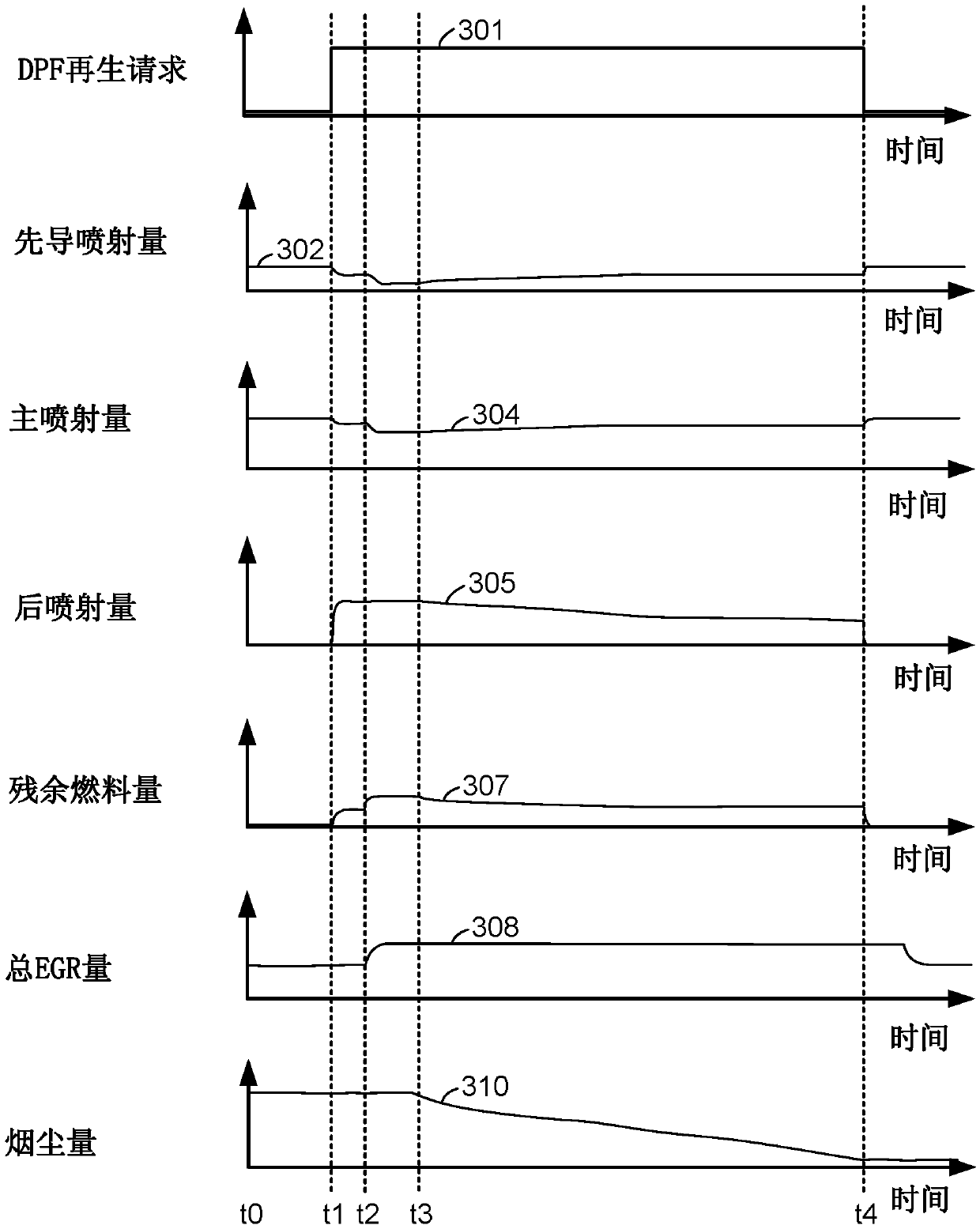

[0012] The present invention relates to controlling the fuel supplied to a diesel engine. figure 1 An example of a supercharged two-stroke diesel engine is shown, but the methods described herein are equally applicable to four-stroke diesel engines. and, figure 1 The diesel engine in is an opposed-piston engine, but the methods described herein can also be applied to two-stroke engines that contain a single piston per engine cylinder. figure 2 A block diagram showing the manner in which fuel injection is adjusted. The fuel injection sequence for a diesel engine is in image 3 is shown in . A method for supplying fuel to a diesel engine in Figure 4 is shown in .

[0013] refer to figure 1 , containing multiple cylinders (one of which is in figure 1 An opposed-piston internal combustion engine 10 shown in ) is controlled by an electronic engine controller 12 . The controller 12 receives from figure 1 signals from various sensors and utilizes based on the received sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com