Humidifier

A technology for humidifiers and heating tanks, which is applied in air humidification systems, heating methods, lighting and heating equipment, etc. It can solve the problems of water shortage in heating tanks, equipment failures, dry heating of heating rods, etc., and achieve the effect of preventing dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

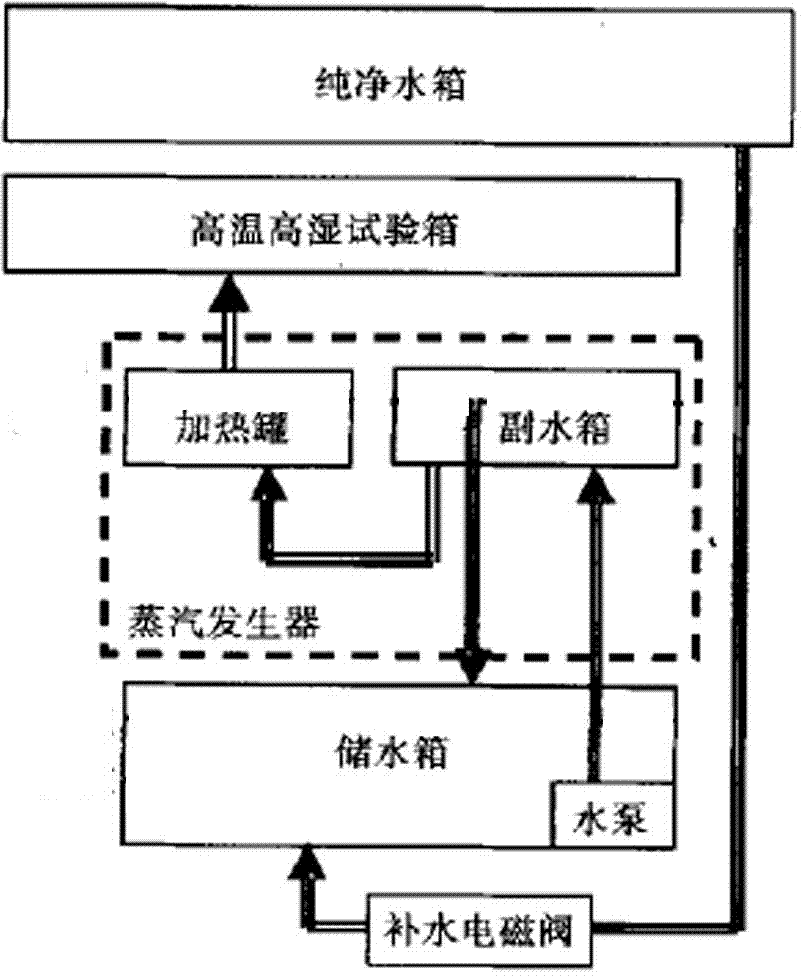

[0014] A humidifier is composed of a pure water tank, a steam generator, a high-temperature and high-humidity test chamber, a water storage tank, and a water replenishment solenoid valve; wherein, the pure water tank is connected to the water storage tank through a water replenishment solenoid valve, and the water storage tank is connected to the steam generator and the high-temperature and high-humidity test chamber. The boxes are connected sequentially.

[0015] The steam generator generates steam through the electric heating rod to maintain the high humidity environment in the test chamber. The steam generator includes a heating tank and an auxiliary water tank, the electric heating rod is installed in the heating tank, and the heating tank is connected with the test chamber through the air outlet. The bottom of the heating tank and the auxiliary water tank are connected by pipes to ensure that the liquid levels in the heating tank and the auxiliary water tank are consisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com