Method for rapidly judging poor insulation of soft package lithium ion battery aluminium-plastic film

A lithium-ion battery and ion battery technology, which is applied in the direction of testing dielectric strength, material breakdown voltage, etc., can solve the problem of long detection period, poor insulation of aluminum-plastic film, unfavorable heat-sealing parameters or optimization and adjustment of heat-sealing equipment operating conditions, etc. problems, to achieve the effect of convenient operation, guaranteed stability, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

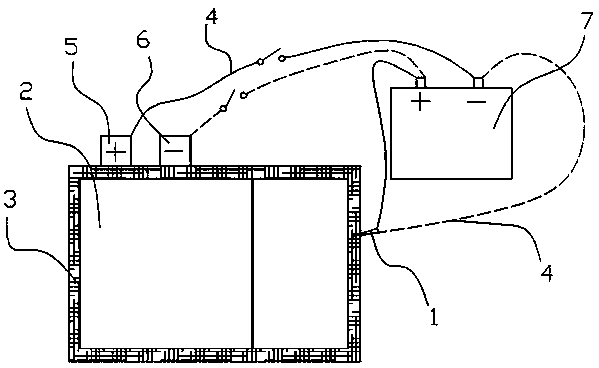

[0024] (1) Take a heat-sealed soft-pack lithium-ion battery 2. The aluminum-plastic film used to pack the soft-pack battery 2 is the aluminum-plastic film of DNP company in Japan, the model is D-EL40H. The packaged lithium-ion battery is placed at 30°C for 5 hours, and the probe 1 is pierced into any edge 3 of the soft-packed lithium-ion battery 2 (see figure 1 ), make the probe 1 contact with the aluminum layer in the aluminum-plastic film of the sealing side 3, and then connect the probe 1 and the positive ear 5 of the soft-packed lithium-ion battery to the two poles of the adjustable voltage DC power supply 7 through the wire 4, The voltage of the adjustable voltage DC power supply 7 is 400V.

[0025] (2) Turn on the power supply. If the edge 3 of the soft-pack lithium-ion battery 2 leaks, breaks down or smokes, it means that the aluminum-plastic film at this position on the edge 3 is poorly insulated. The heat-sealing parameters of the plastic film or the operating condit...

Embodiment 2

[0028] (1) Take a heat-sealed soft-packed lithium-ion battery. The aluminum-plastic film used to pack the soft-packed battery cell is the aluminum-plastic film of DNP Company in Japan, the model is D-ND405. First, heat-seal the soft-packed lithium-ion battery Place the ion battery at 45°C for 3 hours, and pierce the probe 1 into any edge 3 of the soft-pack lithium-ion battery 2 (see figure 1 ), make the probe 1 contact with the aluminum layer in the aluminum-plastic film of the sealing edge 3, and then connect the probe 1 and the negative ear 6 of the soft-packed lithium-ion battery to the two poles of the adjustable voltage DC power supply 7 through the wire 4, The voltage of the adjustable voltage DC power supply 7 is 500V.

[0029] (2) Turn on the power supply. If the edge 3 of the soft-pack lithium-ion battery 2 leaks, breaks down or smokes, it means that the aluminum-plastic film at this position on the edge 3 is poorly insulated. The heat-sealing parameters of the plast...

Embodiment 3

[0032] (1) Take a heat-sealed soft-packed lithium-ion battery. The aluminum-plastic film used to pack the soft-packed battery cell is the aluminum-plastic film of DNP company in Japan, the model is D-ND408. First, heat-seal the soft-packed lithium-ion battery. Place the ion battery at 50°C for 1 hour, and pierce the probe 1 into any edge 3 of the soft-packed lithium-ion battery 2 (see figure 1 ), make the probe 1 contact with the aluminum layer in the aluminum-plastic film of the sealing side 3, and then connect the probe 1 and the positive ear 5 of the soft-packed lithium-ion battery to the two poles of the adjustable voltage DC power supply 7 through the wire 4, The voltage of the adjustable voltage DC power supply 7 is 700V.

[0033] (2) Turn on the power supply. If the edge 3 of the soft-pack lithium-ion battery 2 leaks, breaks down or smokes, it means that the aluminum-plastic film at this position on the edge 3 is poorly insulated. The heat-sealing parameters of the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com