A control cabinet and humidity control method based on molecular sieve dehumidification

A humidity control and control cabinet technology, applied in humidity control, non-electric variable control, control/regulation systems, etc., can solve problems such as poor humidity control effect, accurate humidity control, and lack of understanding of the hygroscopic properties of molecular sieves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

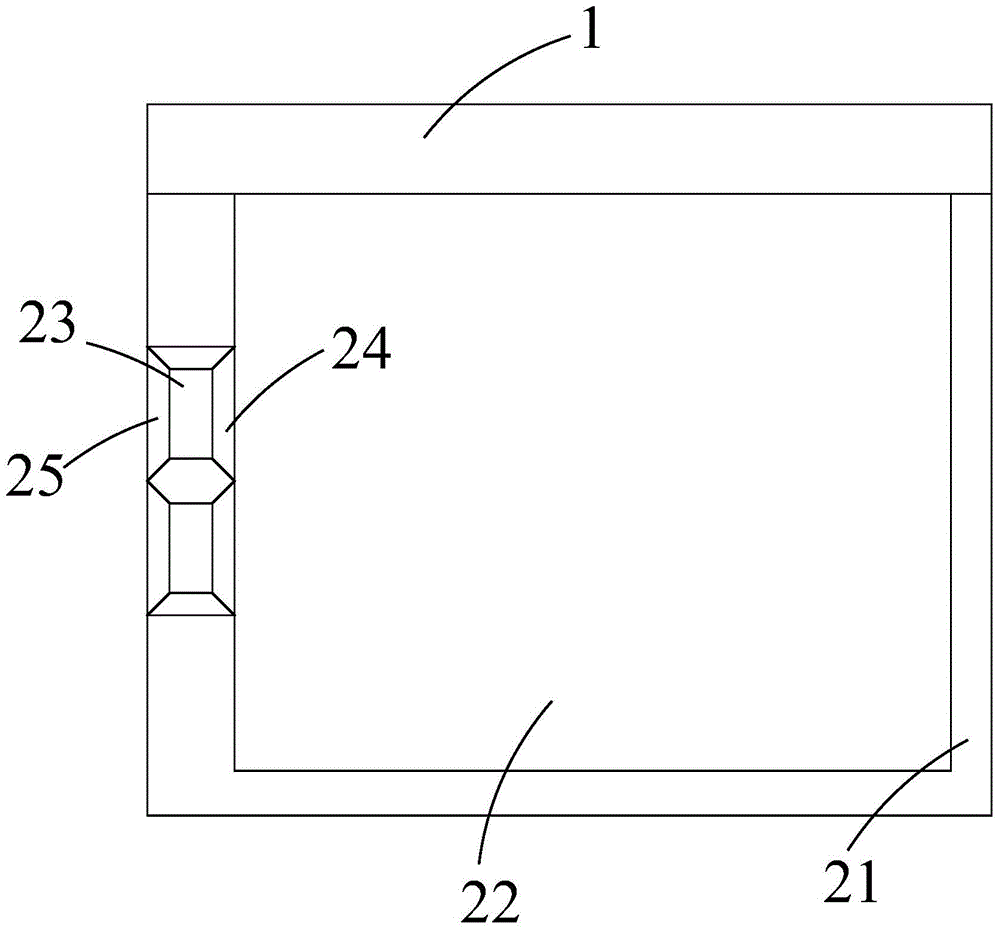

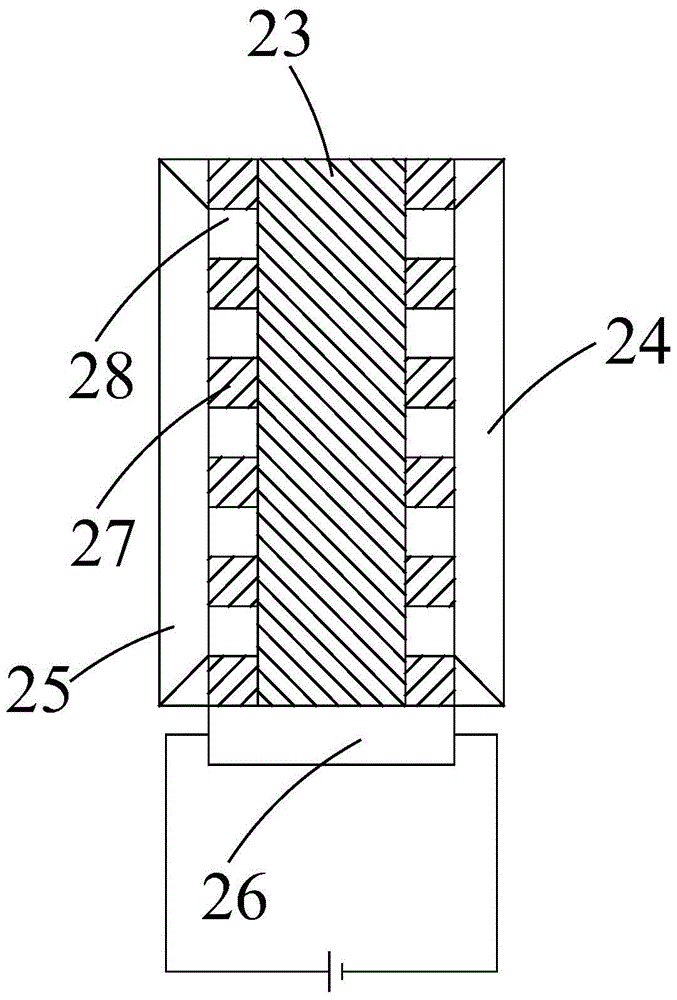

[0025] Embodiment 1, Figure 1 ~ Figure 3 A control cabinet humidity control method based on molecular sieve dehumidification is given.

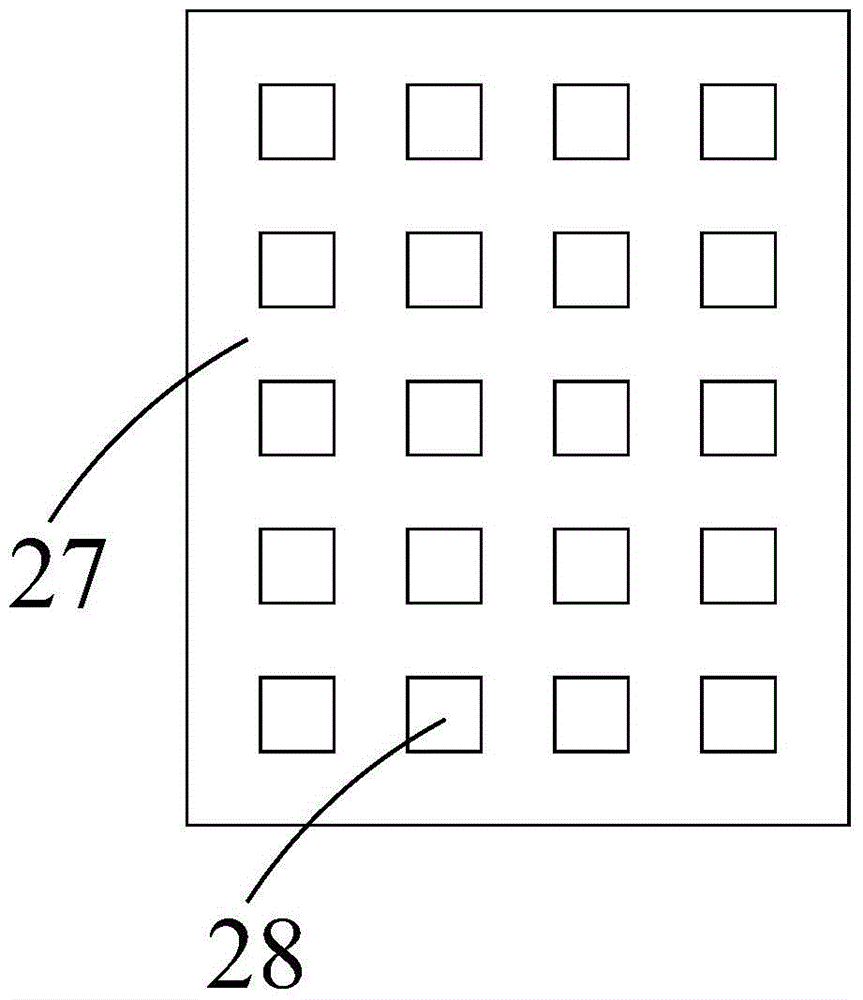

[0026] The method is implemented based on a control cabinet based on molecular sieve dehumidification, the control cabinet includes a control cabinet 1, and a storage space 22 and a dehumidification system are arranged in the control cabinet 1; the storage space 22 cooperates with the cabinet door 21 to form a closed space; the dehumidification system It includes a moisture absorption valve 24 and a moisture discharge valve 25, and a moisture absorption layer is arranged between the moisture absorption valve 24 and the moisture discharge valve 25; the moisture absorption layer includes a shell 27 made of a mesh aluminum alloy material, and a molecular sieve layer 23 is arranged inside the shell 27; One side of the casing 27 is provided with a moisture absorption valve 24, and another moisture discharge valve 25 is arranged in turn; the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com