Width Control Method of Wedge Blank Based on Fixed Width Side Press

A technology of width control and side pressing machine, which is applied in rolling mill control devices, manufacturing tools, metal rolling, etc., to achieve the effects of reducing width fluctuations, improving stability and yield, and large reduction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

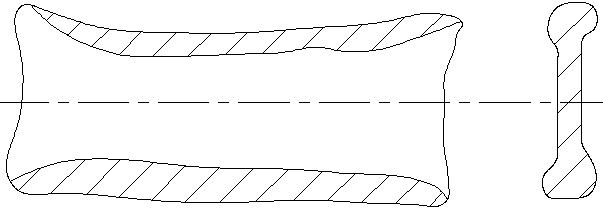

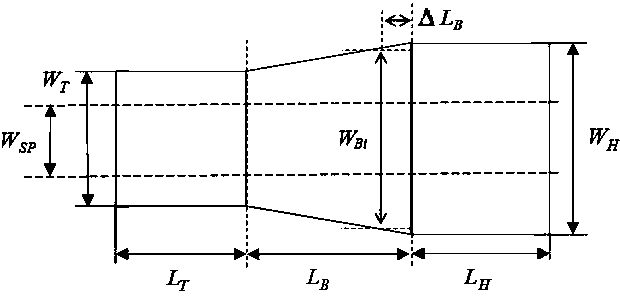

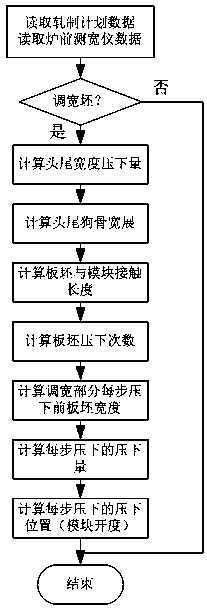

[0068] Such as image 3 As shown, a wedge-shaped blank width control method based on a fixed-width side press machine takes the slab with unequal head and tail width as the wedge-shaped blank, and sets the target width of the slab to be processed; the shape of the wedge-shaped blank to be processed is as follows figure 2 shown, where W H is the width of the equal width section of the head, W T is the width of the equal-width segment at the tail, W SP is the target width, L H is the length of the equal width section of the head, L T is the length of equal width segment at the tail, L B It is the length of the width adjustment section in the middle; the size parameters of the above-mentioned wedge-shaped billet are issued by the host computer or measured by the width measuring instrument in front of the furnace;

[0069] After the slab to be processed is determined to be a wedge-shaped slab from the obtained slab size parameters, follow the steps below:

[0070] S1: Divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com