Temperature control system for mixed air heating and control method thereof

A temperature control system and control method technology, applied in the direction of combustion control, combustion method, lighting and heating equipment, etc., can solve the problems of low precision, unstable oven temperature control, blank in the field of ultra-high temperature oven temperature control, etc., to achieve reduction Small production cost, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with the accompanying drawings and specific embodiments.

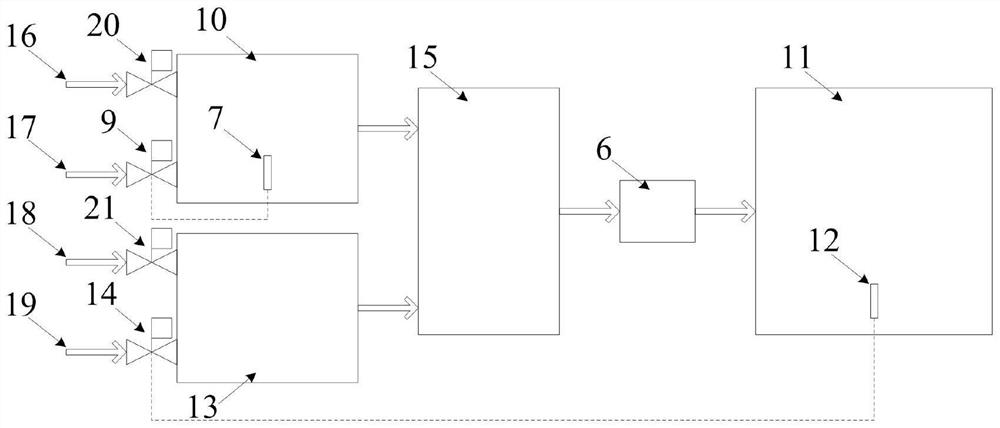

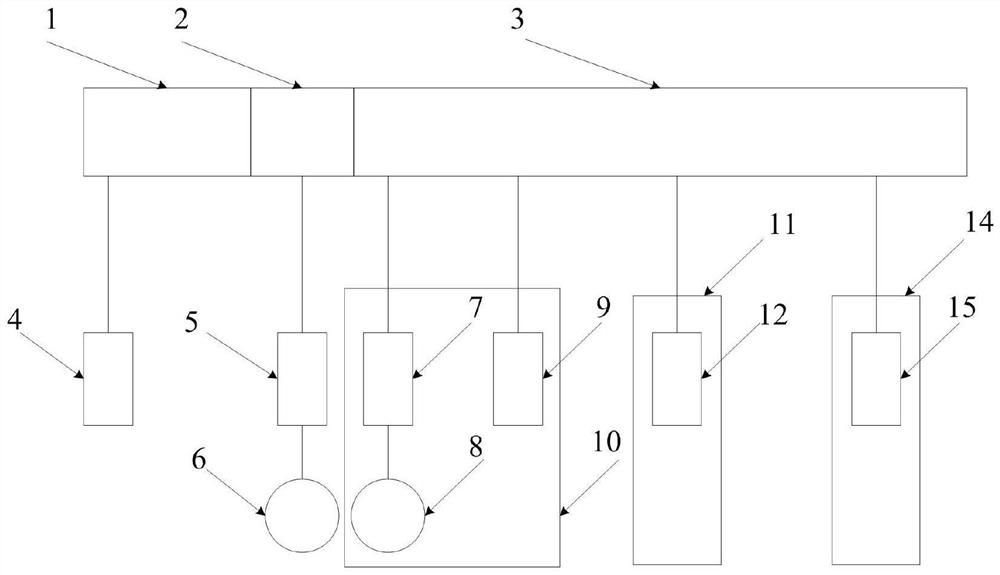

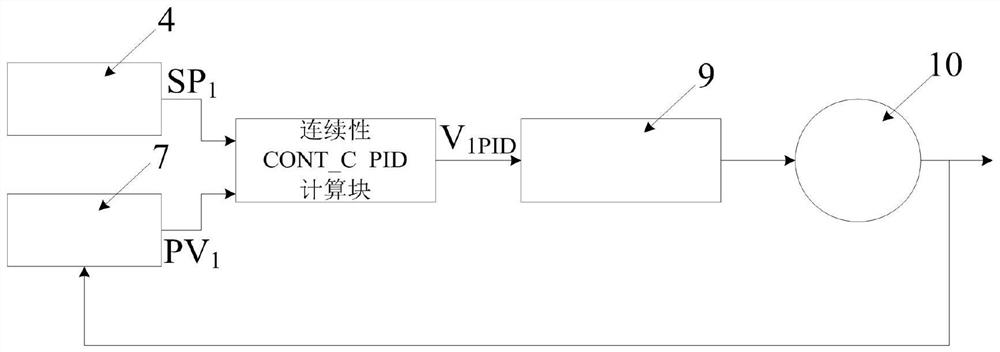

[0040] The present invention is a temperature control system for mixed air heating, such as Figure 1 、 2 Shown, comprising a power supply module 1, power module 1 sequentially with the CPU module 2 (CPU module 2 is a CPU module of the PLC), analog input and output module 3 is connected to the rail installed in the distribution cabinet, CPU module 2 controls the cold air electric valve 9 and the natural gas electric valve 14 through the analog input and output module 3, the cold air electric valve 9 controls the size of the cold air entering the primary mixing box 10, the natural gas electric valve 14 controls the amount of natural gas inlet into the combustion furnace 13, Primary mixing box 10 is equipped with a mixing box PT100 thermocouple 7, a mixing box PT100 thermocouple 7 will be the actual temperature in the box through the primary mixing box t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com