Long-distance curved jacking pipe and pipe roof construction technique

A construction technology, long-distance technology, applied in mining equipment, tunnels, earth-moving drilling and other directions, can solve problems such as difficult to complete the process, and achieve the effect of improving the level of construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

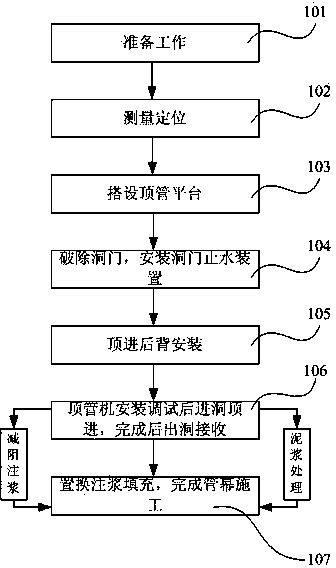

Method used

Image

Examples

Embodiment

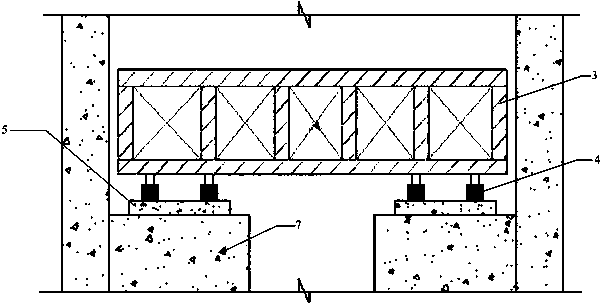

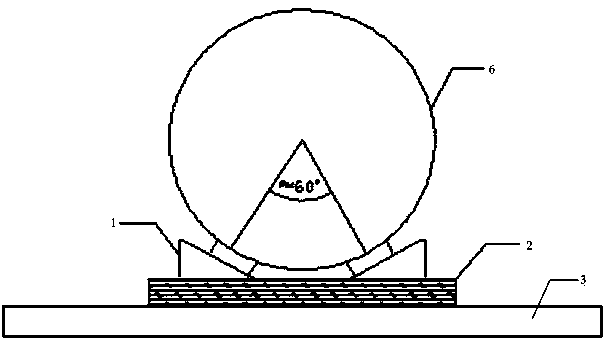

[0032] This embodiment takes the pipe curtain construction of the Gongbei Tunnel excavation section of the Hong Kong-Zhuhai-Macao Bridge Zhuhai Connection Line as an example to illustrate. The average length of the pipe curtain described in this embodiment is 257.927m / root, which is the longest in China at present, located at the radius of curvature R =885.852m~906.298m on the transitional curve and circular curve, there are 36 pipe curtains of φ1620mm (wall thickness 20mm). Such large-section pipe curtain groups are rare in China and abroad. There are two test pipe curtains, 6 in the middle plate stage, and 28 in the group pipe jacking stage. The distance between the pipe curtains is about 35.7cm, and the shortest distance between the pipe curtains and the pile foundation of the port building is 50cm. The opening angle of each section on the transition curve needs to be adjusted during the jacking process (controlled within 3mm). The opening angle between the joints is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com