Method for monitoring pile foundation construction quality and reinforcing pile foundation by electric exploring method

A technology of construction quality and electric detection, which is applied in the direction of basic structure engineering, basic structure test, material impedance, etc., can solve the problems of no major progress and inability to detect the results of concrete construction quality, so as to improve the guarantee rate and reduce the construction quality Accidents, the effect of improving the level of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

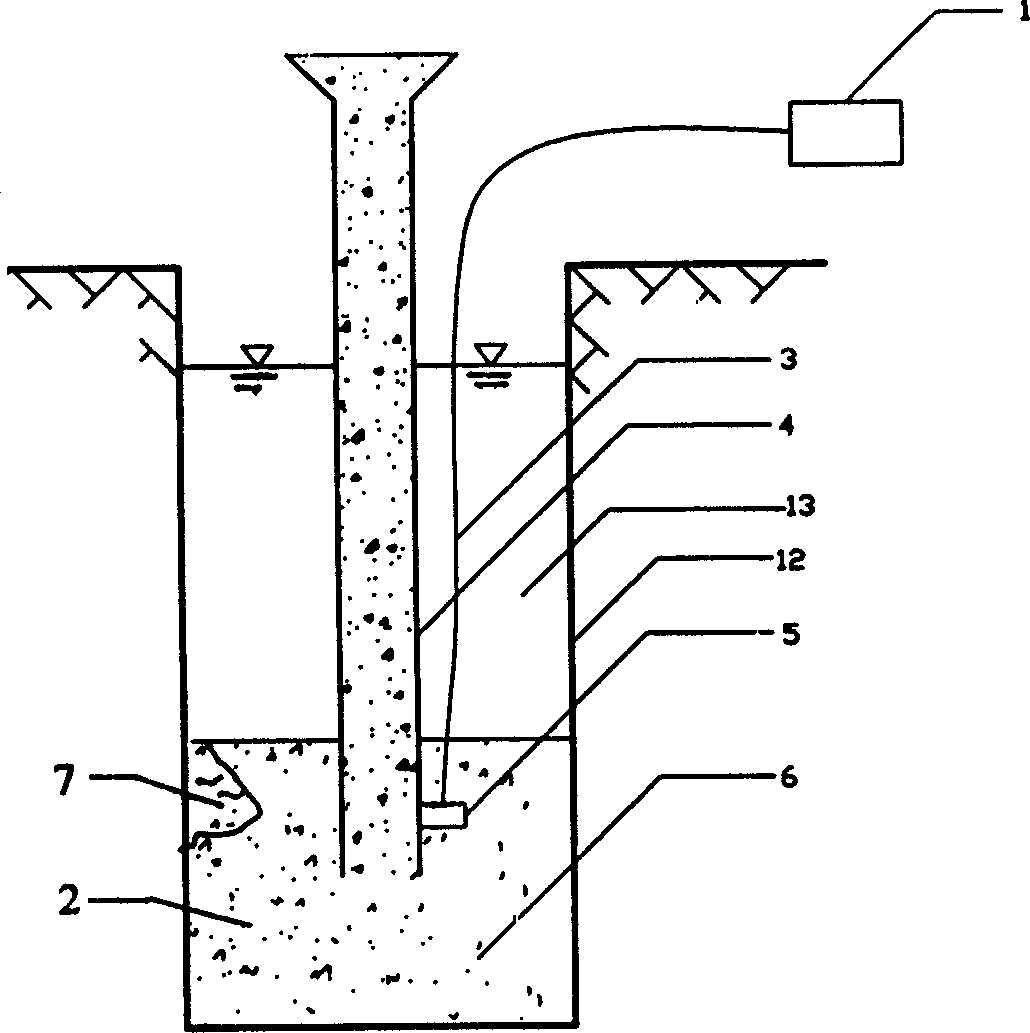

[0027] Pile foundation concrete pouring quality monitoring I

[0028] as attached figure 1 As shown, the hole 12 of the pile foundation 2 is mud 13 before concrete pouring. The electric detector 1 is connected and installed on the outer periphery of the outlet of the conduit 4 through the wire 3, and the sensor 5 made of two fixed electrodes measures the change of the voltage Vr caused by the change of the medium resistance to analyze the pouring quality of the concrete mixture 6, The state of the segregated concrete mixture 7 is judged.

[0029] 1. Calibrate the instrument according to the following requirements before testing.

[0030] 1.1 Prepare the concrete mixture according to the design requirements.

[0031] 1.2 Take the silt and mud deposited at the bottom of the pile, weigh the silt and mud with SN of 5.0%, 10.0%, 20.0%, 30.0%, 40.0%, 50.0%, and 60.0% respectively, and add them to the concrete mixing step by step and mix the segregated concrete mixture 7 in the s...

Embodiment 2

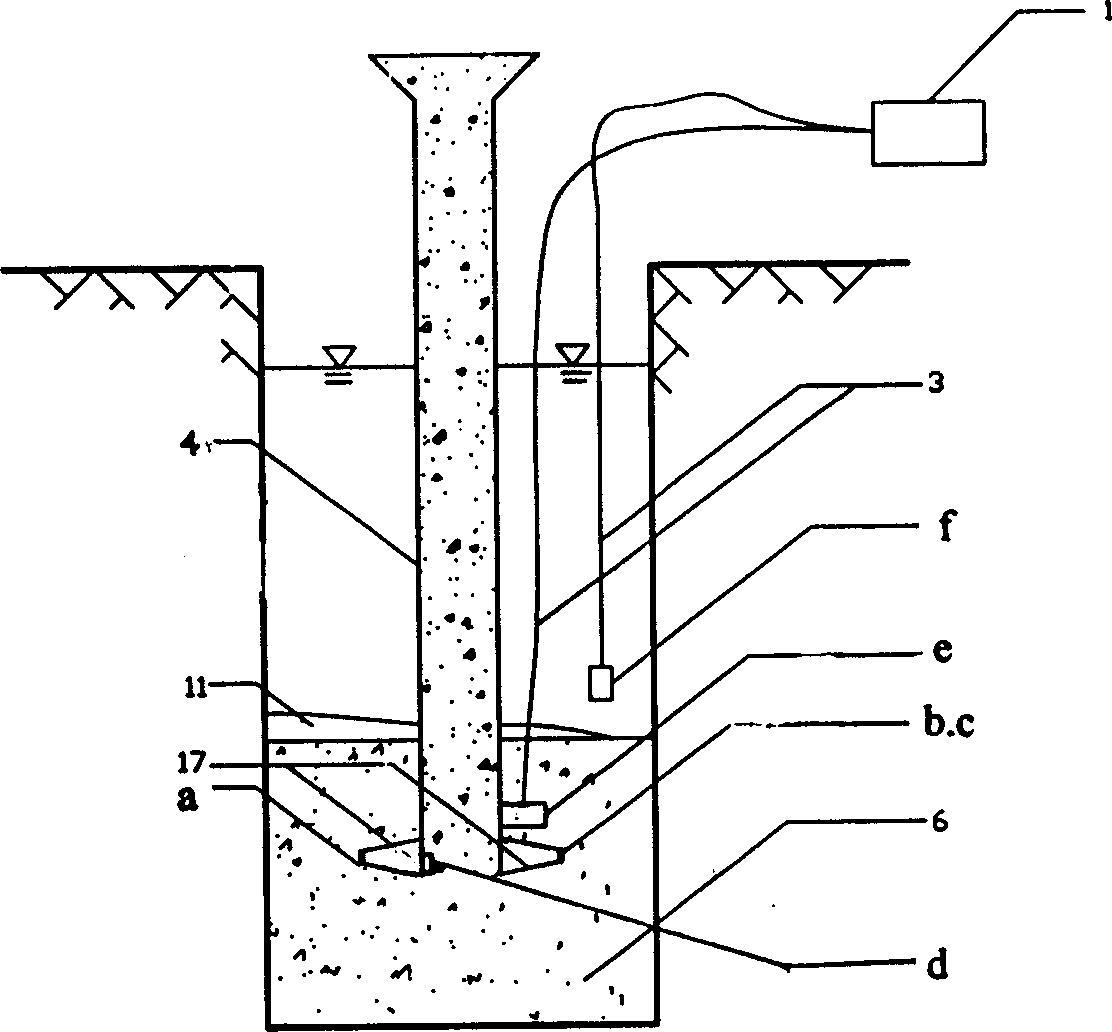

[0062] Pile foundation concrete pouring quality monitoring II

[0063] as attached figure 2 As shown, three sensors a, b, and c are evenly fixed and installed on the outer periphery of the outlet of the conduit 4 through the positioning member 17, and the nature of the concrete defect is defined according to the following method:

[0064] 1. The Vri of the three measuring points of a, b, and c are not less than Vrd, which means concrete segregation.

[0065] 2. If Vri is less than Vrd within any two measuring points of a, b, and c, it is a constriction.

[0066] 3. If the Vri of the three measuring points a, b, and c are all less than Vrd, the pile is broken.

[0067] The size of the aforementioned concrete defects is determined by the plane positions and elevations of the three sensors.

[0068] A sensor d is fixedly installed on the inner wall of the outlet of the conduit 4, and the channel d is selected to be displayed when the ball is sheared, so as to observe whether ...

Embodiment 3

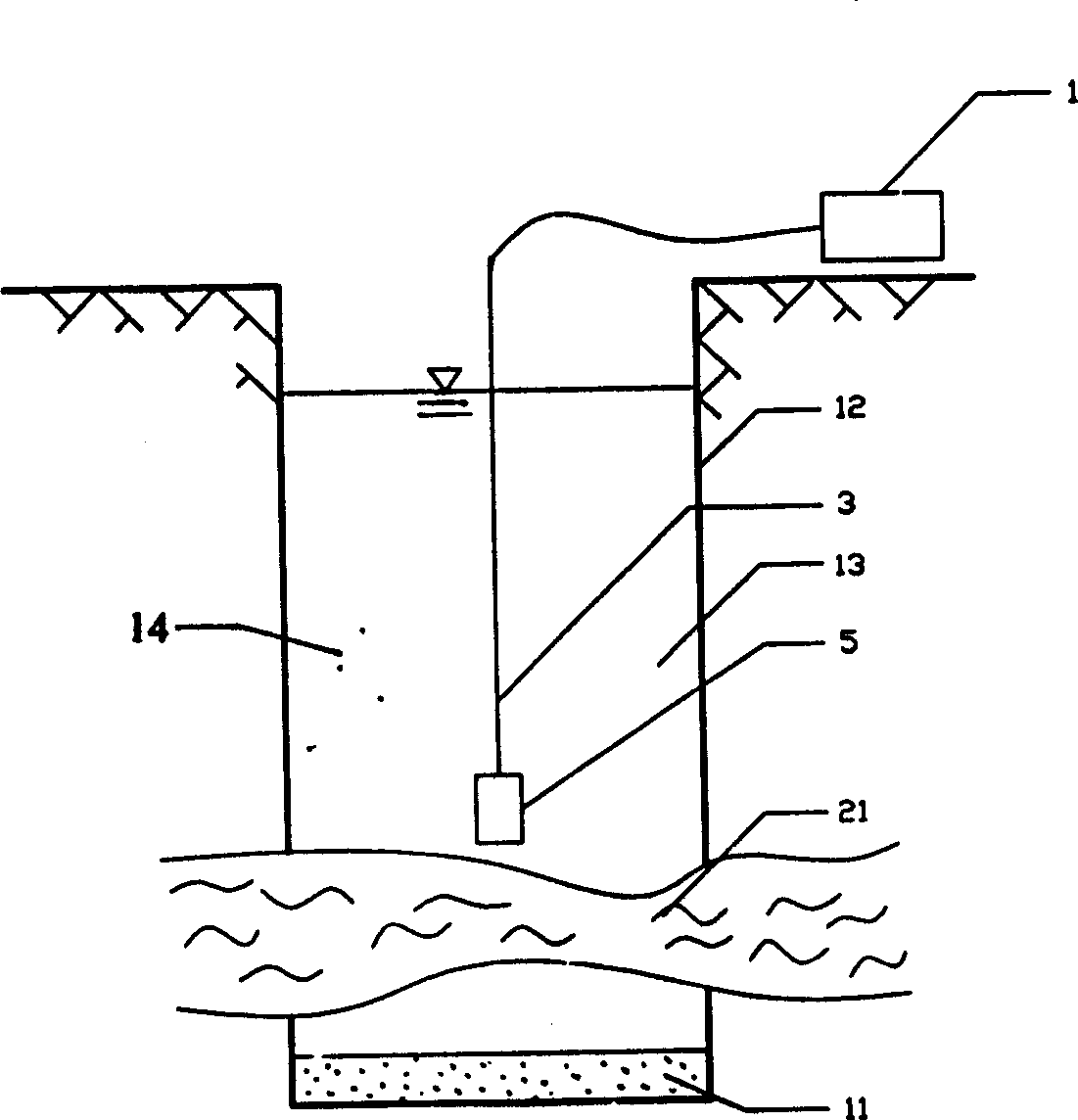

[0072] Clean hole quality inspection

[0073] as attached image 3 As shown, the electric probe 1 puts the sensor 5 into the mud 13 of the hole 12 through the wire 3, measures the content of the sand 14 in the mud 13 and judges the thickness and state of the pile bottom sediment 11, and the detection implementation steps are as follows:

[0074] 1. Use the cleared mud to pass through a sieve with a diameter of about 0.074mm, and take no less than 4000g of pure mud after sieving as the mud with a sand content of 0 for future use. No additional water or other chemical substances should be added during the preparation process to ensure that the pure mud has the same physical and chemical properties as the mud used for engineering piles except for the sand content.

[0075] 2. Take out the sediment outside the pile when cleaning the hole, wash off the mud in the sand with water, dry (dry) and pass through a sieve with an aperture of about 1.5mm, and take 4000g of sand for later u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com