A distance fixed pad

A technology for fixing pads and moving distances, which is applied in the direction of gaskets, connecting components, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

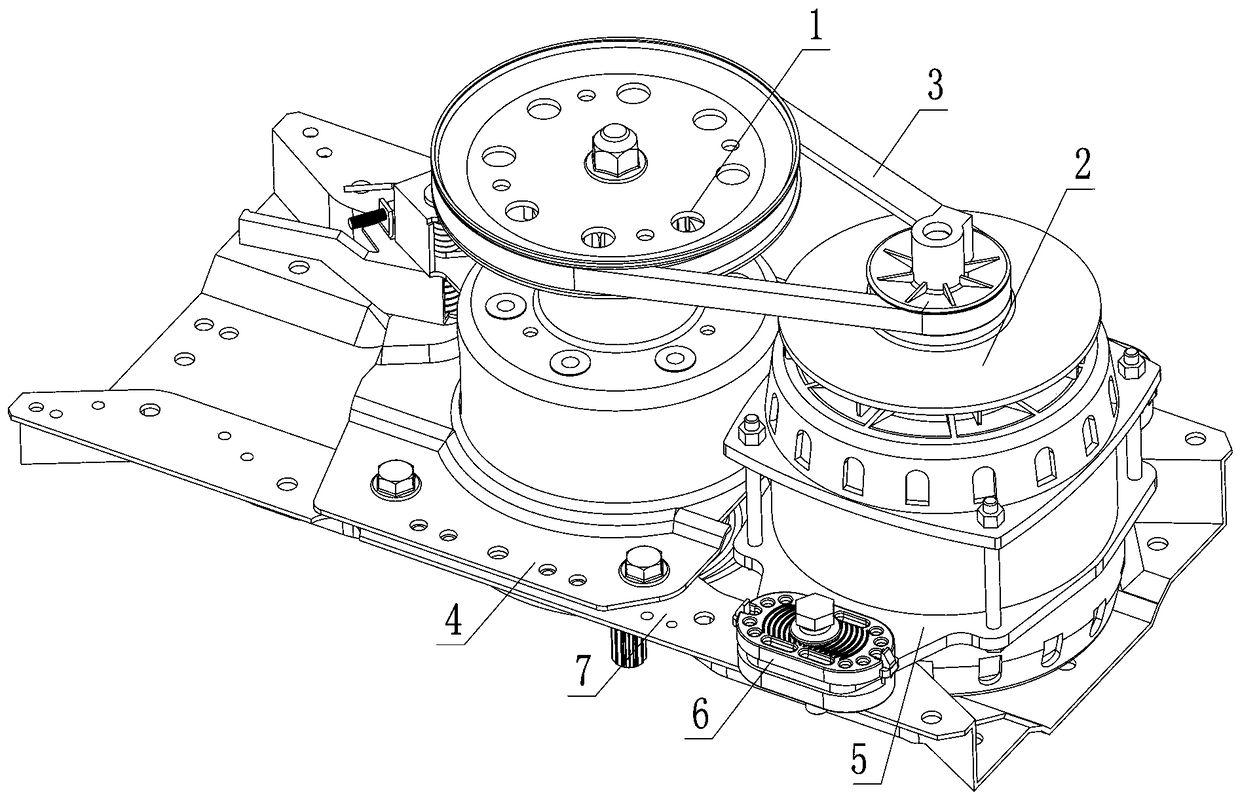

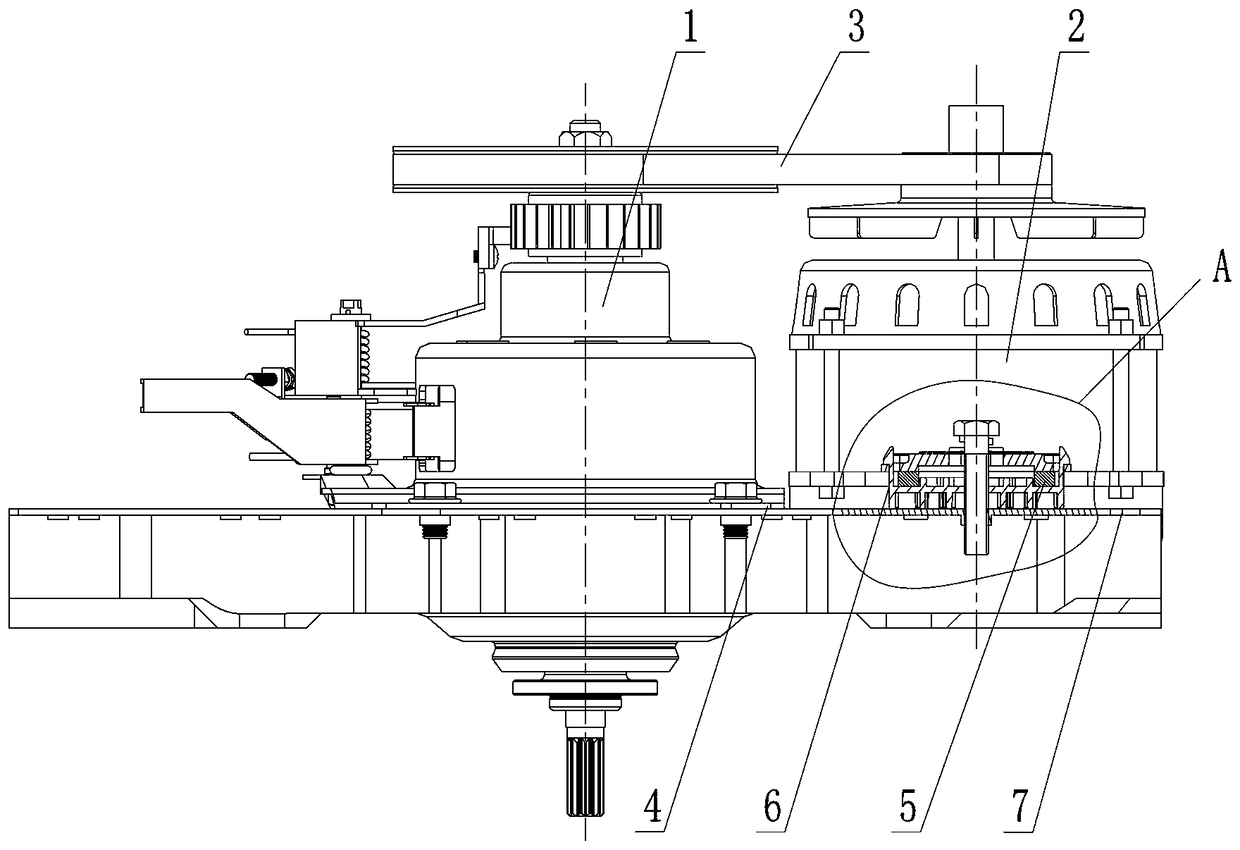

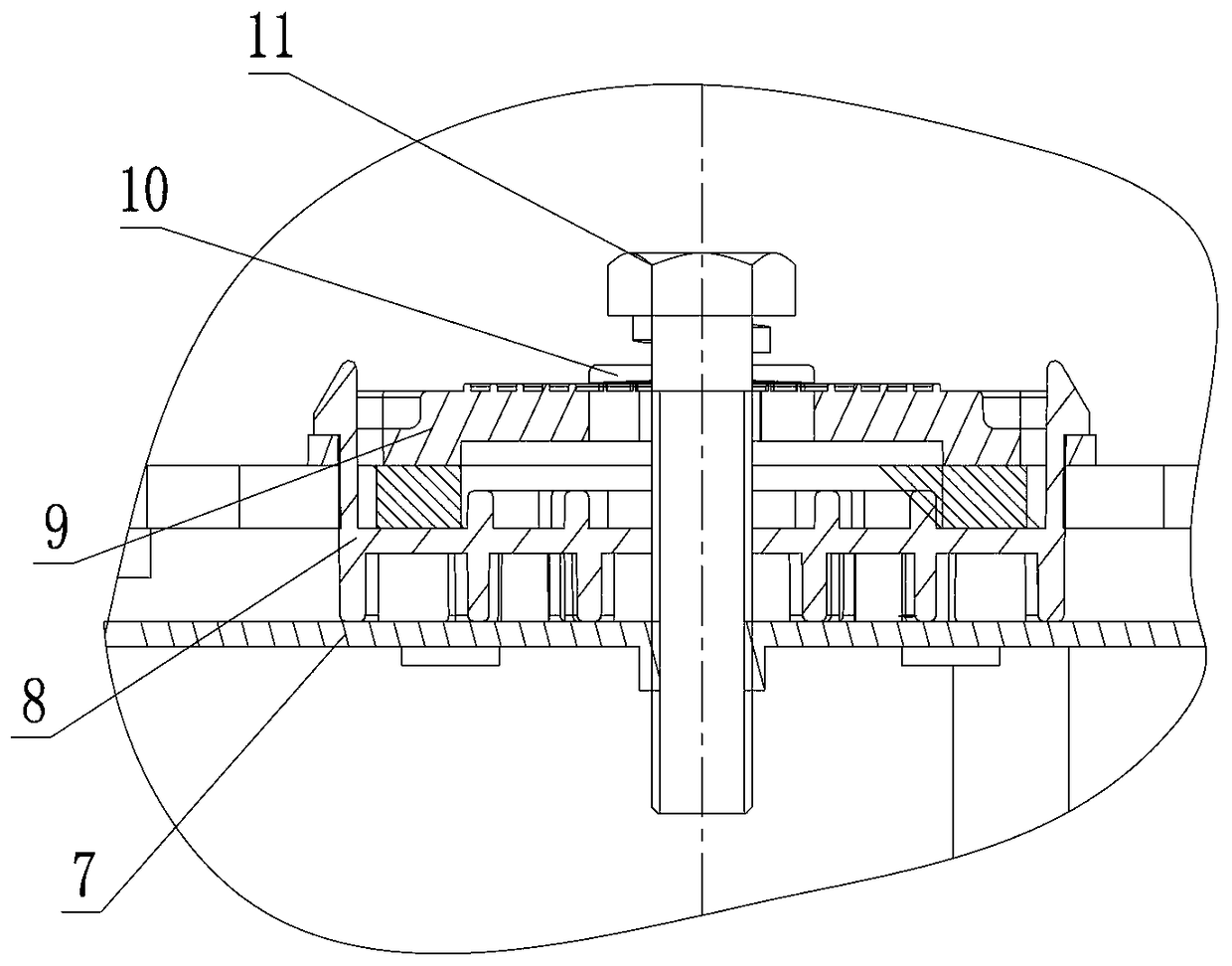

[0036] A moving distance fixing pad 6 according to the present invention is used for fixedly connecting the first connecting piece and the second connecting piece, and the moving distance fixing pad 6 includes a pair of upper and lower fixing pads 9, 8 and a staggered tooth washer 10 , the upper and lower fixed pads 9, 8 and the staggered tooth washers 10 are provided with through holes for the bolts 11 to pass through, and at least the upper fixed pads 9 and the staggered tooth washers 10 are provided with a raised structure with an anti-loosening function 16.

[0037] The relative position requirements of the first connecting piece and the second connecting piece remain unchanged during work, and the raised structure on the upper fixed pad 9 and the raised structure on the staggered tooth washer 10 are interlocked to prevent loosening and misalignment caused by high-frequency vibration during work. Ensure that the relative positions of the first connecting part and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com