Craft disc bracket and manufacturing method thereof

A production method and technology, applied in the field of craft plate brackets and their production, can solve the problems that the display of craft plates cannot achieve good results and have single functions, and achieve the effect of diverse and beautiful shapes and artistic value of the brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

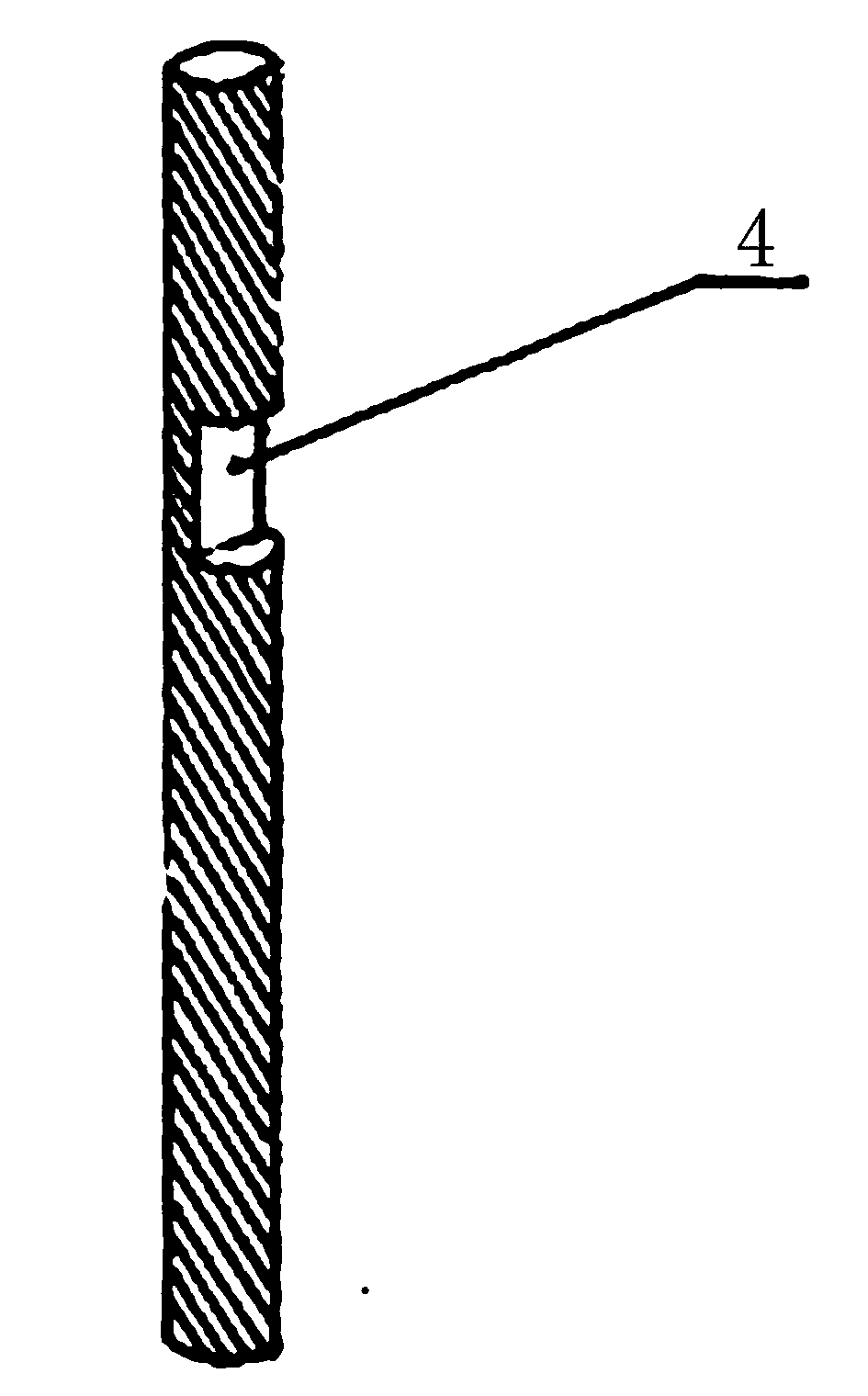

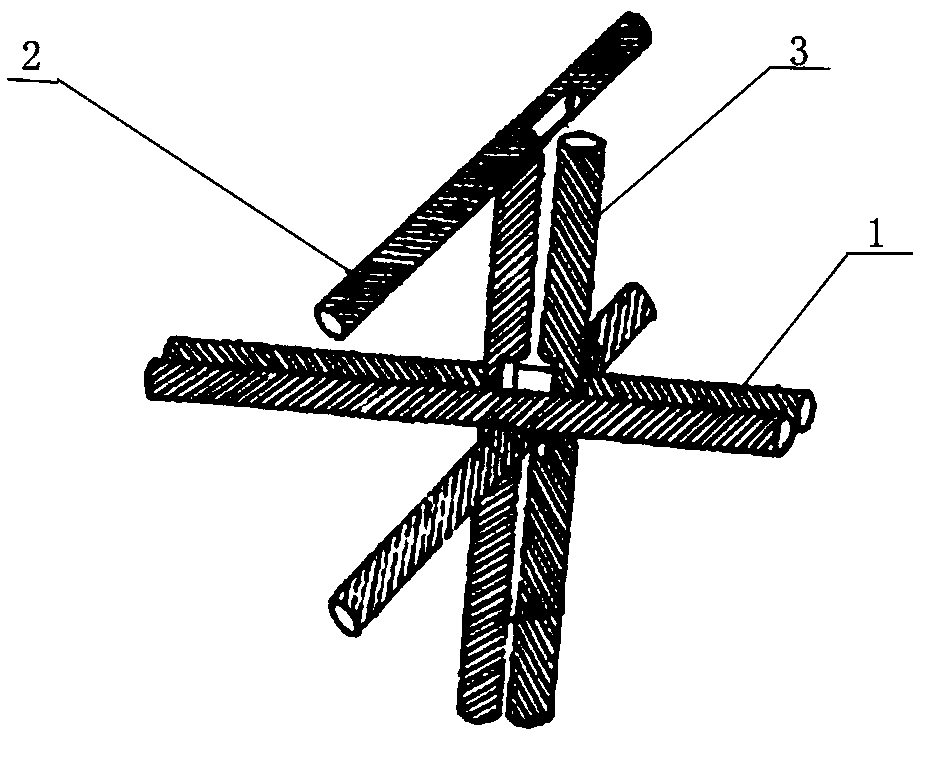

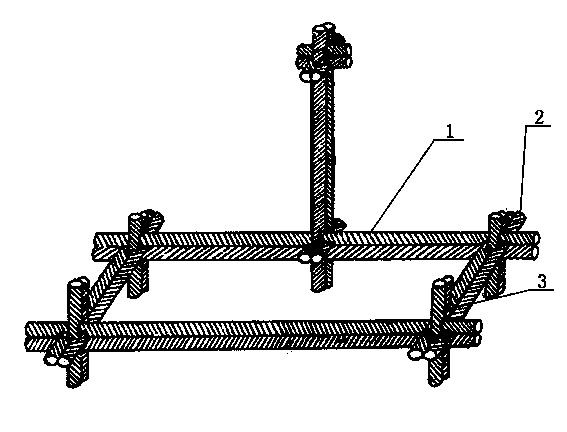

[0013] Such as image 3 As shown, the present embodiment is a kind of craft plate bracket, wherein: comprises the wooden column that has tenon 4, and described wooden column has twenty-four, and described twenty-four wooden column is made up of six long wooden columns 1 , four middle wooden columns 2, and fourteen short wooden columns 3; two long wooden columns 1 in the 24 wooden columns and one end of the two middle wooden columns 2 are vertically intersected, and pass through each wooden column The tenon 4 on the top is stuck, and then stuck by the tenon 4 on the two short wooden columns 3, the other ends of the two middle wooden columns 2 are vertically crossed with the ends of the other two long wooden columns 1, and passed through The tenon 4 on each wooden column is stuck, and then stuck by the tenon 4 on the two short wooden columns 3, and so on, enclosing a rectangular shape, and one end of the last two long wooden columns 1 is vertical through the tenon 4 The cross i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap