A 3D printing method for hollowing out the surface of a customized model

A custom model, 3D printing technology, applied in the direction of 3D modeling, digital output to printing units, instruments, etc., can solve problems such as not enough to meet user requirements, users can not customize the model operation, etc., to achieve the effect of lightweight frame structure

Active Publication Date: 2017-12-05

SHANDONG UNIV

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In view of the above reasons, some easy-to-use 3D printing-oriented model customization tools have appeared, especially in jewelry design. However, these tools either only provide very simple stylized options, or require users to use system preset models , the user cannot perform customized operations on the model specified by himself

In addition, there are various requirements for the stylized design of 3D models, and the current tools are far from enough to meet user requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

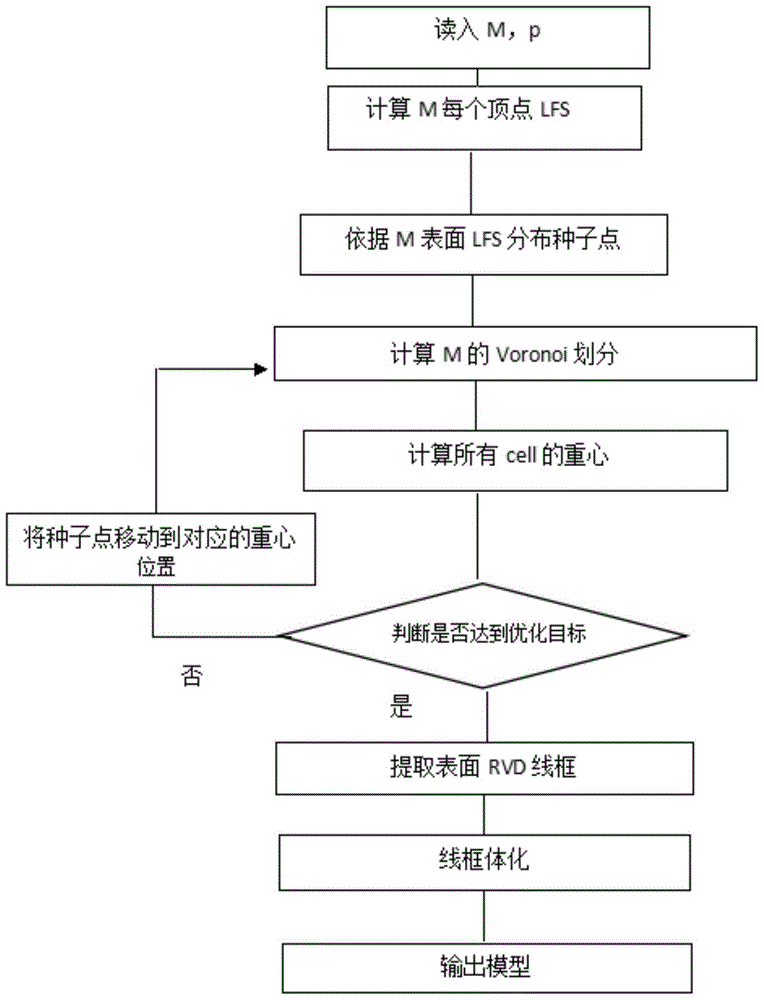

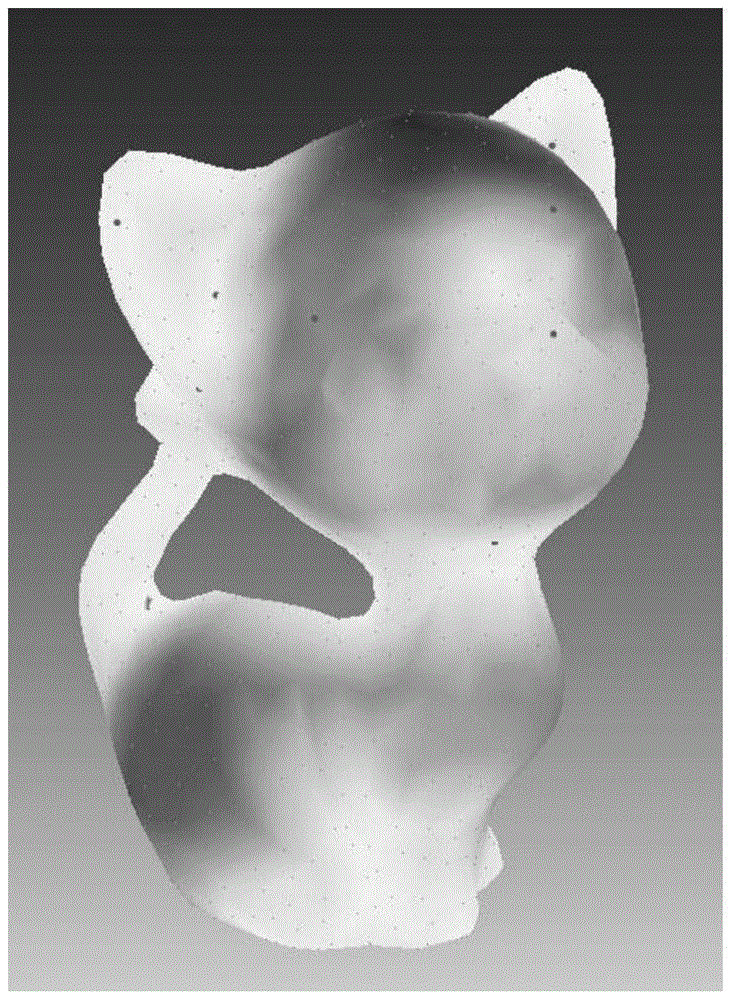

The invention discloses a 3D printing method based on a user-defined surface hollow model. The method comprises the following steps: performing normalization and grid processing on the user-defined three-dimensional model, and calculating LFS values of all apexes of the three-dimensional model; initializing a seed point number of the three-dimensional model, arranging seed points on the three-dimensional model according to the distribution of the LFS values of all of the apexes of the three-dimensional model; calculating Voronoi division of the seed points in a three-dimensional space to be intersected with the three-dimensional model to obtain a restricted Voronoi diagram RVD set; calculating whether displacement quadratic sum of all of the seed points on the three-dimensional model is smaller than a preset threshold value or not, if yes, performing the next step, and if no, optimizing positions of the seed points on the three-dimensional model by adopting a Lloyd iteration method, and returning to the former step; generating a corresponding three-dimensional model file; inputting the generated three-dimensional model file into a 3D printer, and printing the user-defined three-dimensional model through the 3D printer.

Description

A 3D printing method for hollowing out the surface of a custom model technical field The invention relates to the field of geometric model customization oriented to 3D printing, in particular to a 3D printing method based on hollowing out the surface of a customized model. Background technique In recent years, 3D printing technology has developed rapidly. With the increase of the optional range of 3D printing molding materials, the improvement of molding accuracy and speed, and the reduction of the price of various equipment, it has begun to be widely used in medical, aviation, entertainment and Various fields such as fashion have even gradually penetrated into the lives of ordinary people. 3D printing is an emerging technology in the field of rapid prototyping. It is a technology based on digital model files and using various adhesive materials to construct a three-dimensional model by layer-by-layer superposition. Compared with traditional manufacturing, 3D printing ha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): G06F3/12G06T17/00B33Y50/00

Inventor 吕琳薄志涛赵海森陈宝权

Owner SHANDONG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap