Cartridge mechanical seal device for corrosion-resistant pump

A technology of mechanical sealing device and corrosion-resistant pump, which is applied to components, mechanical equipment, pumps, etc. of pumping devices for elastic fluids, to achieve wide adaptability, reliable operation, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

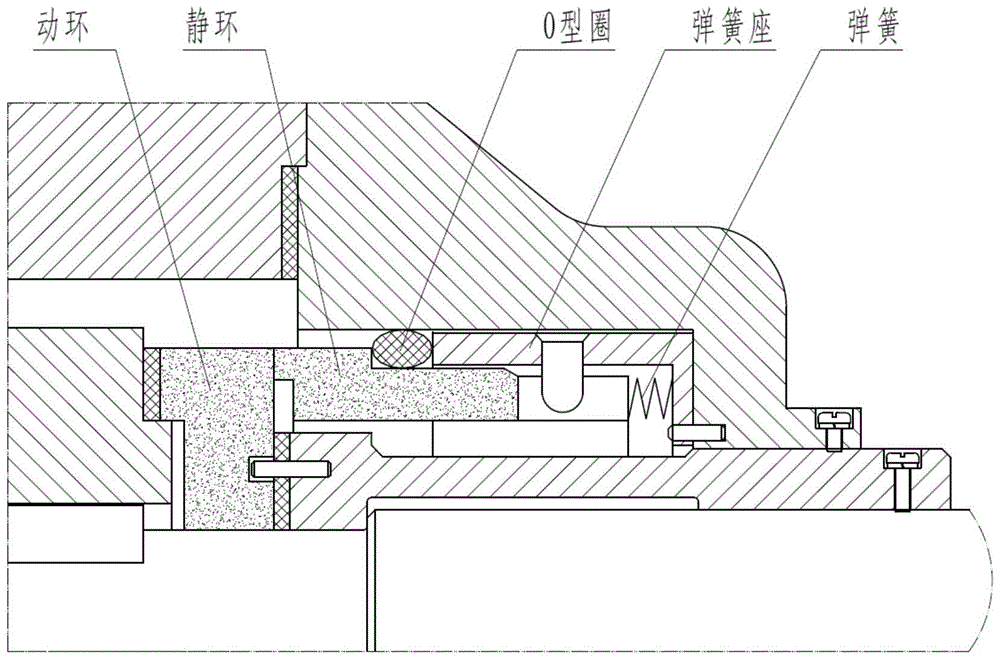

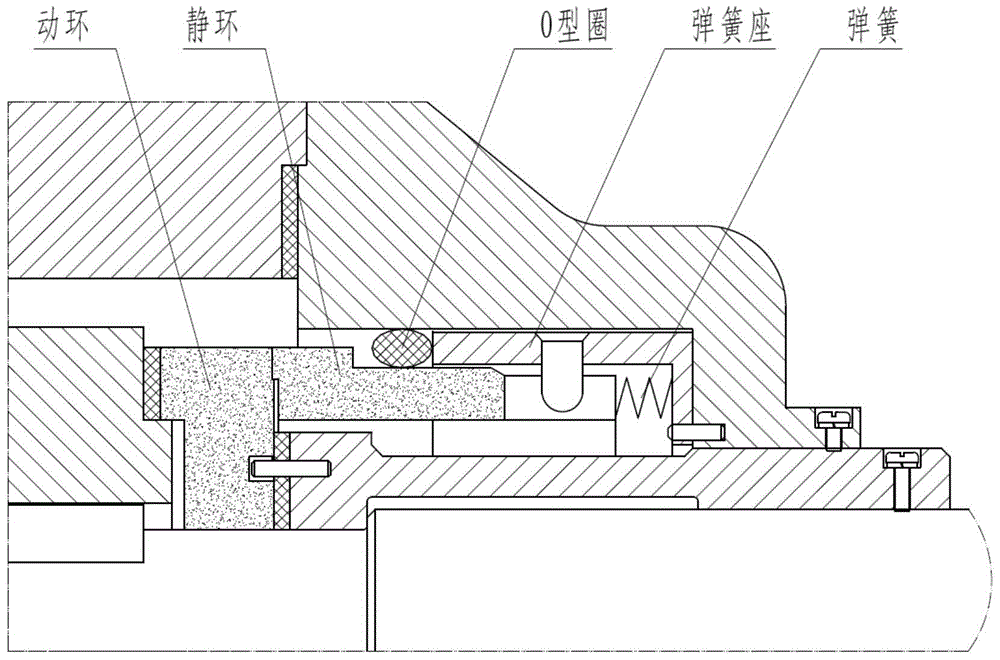

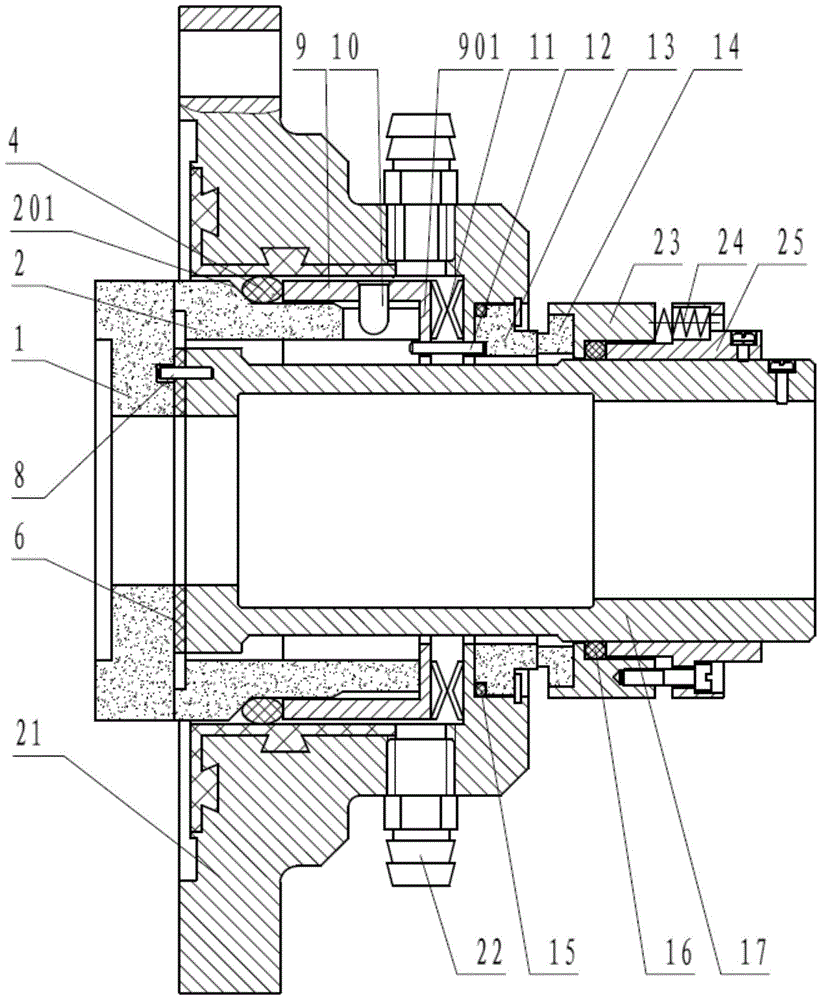

[0026] see image 3 , the corrosion-resistant pump cartridge mechanical seal device disclosed in the present invention is composed of a shaft sleeve 17, a gland 21, a medium end seal located inside the gland, and an atmospheric end water seal located outside the gland, wherein, The surface of the trumpet-shaped inner cavity of the gland 21 is lined with corrosion-resistant fluoroplastics; one end of the shaft sleeve 17 is coaxially installed in the inner cavity of the gland (21), and the medium end seal is sleeved, and the other The headgear is provided with the air end water seal, and is provided with two threaded holes on the outer peripheral surface for fixing screws on the pump shaft.

[0027] The medium end seal includes a moving ring 1, a static ring 2, a sliding sealing ring 4, a moving ring transmission pin 8, a spring seat 9 and a wave plate spring 11, wherein the moving ring 1 is fixed on the shaft sleeve 17 by the moving ring transmission pin On the end face of one...

Embodiment 2

[0035] see Figure 5 ~ Figure 6 The difference between the cartridge mechanical seal device for corrosion-resistant pumps described in this embodiment and Embodiment 1 is that the mouth of the inner cavity of the gland 21 expands radially outward to form a radially expanded portion, and the radially The surface of the expansion part is provided with an annular groove; the medium end seal also includes an anti-lock ring seal 3 and an anti-lock seal ring 7; wherein, the anti-lock seal ring 3 is embedded in the mouth of the inner cavity of the gland 21 In the radial expansion part, the sliding sealing ring 4 is covered therein, and the anti-lock sealing ring 7 is arranged in the annular groove, and the gap between the anti-lock sealing ring 3 and the surface of the inner cavity of the gland 21 is adjusted. seal.

[0036] The anti-lock sealing ring 3 is made of high-purity SiC industrial ceramics, and the material of the anti-lock sealing ring 7 is fluororubber.

[0037] The str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com