Device for locking high-speed bearing

A technology of high-speed bearings and lock nuts, which is applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., which can solve the problems of reduced service life and safety performance, inconvenient maintenance, and reduced shaft torsional performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are used to illustrate specific applications of the present invention, but the present invention is not limited thereto.

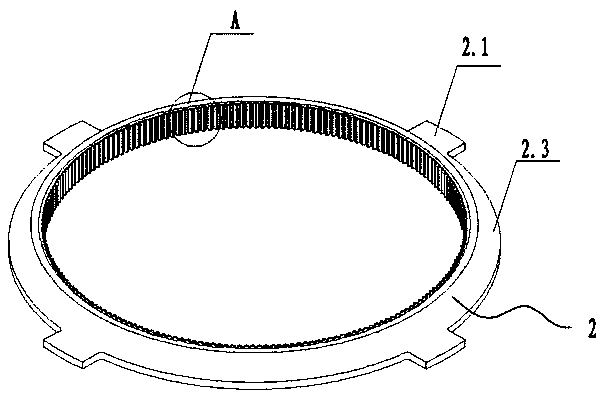

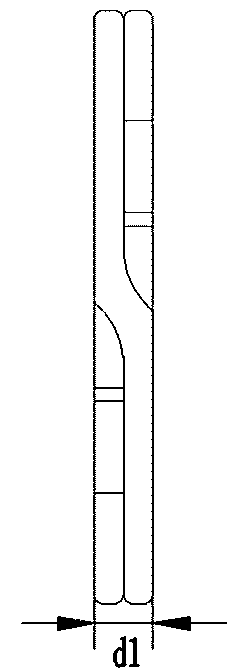

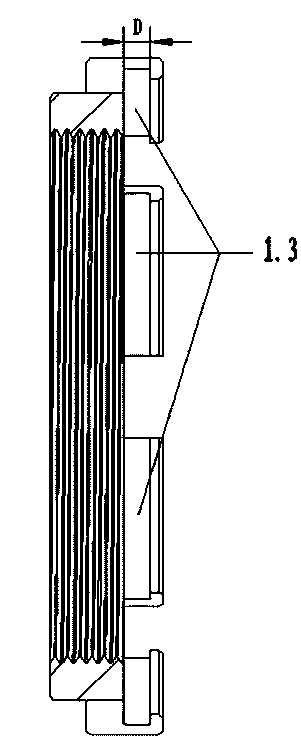

[0023] As shown in the drawings: a device for high-speed bearing locking, a device for high-speed bearing locking, characterized in that the device includes a lock nut 1, a stop washer 2 and a circlip 3; The lock nut 1 includes a body 1.1, the inner wall of the body is provided with an internal thread for screwing in with the external thread on the shaft 4 on which the high-speed bearing is installed, and the external thread on the shaft 4 is provided with several parallel to the axis. The first anti-loosening tooth 4.1; the outer peripheral wall of the body 1.1 is provided with a plurality of radially outward and axially outward protrusions 1.2 evenly distributed, and the inner wall of the axially outward part of the protrusion 1.2 is provided with a In the groove 1.3 for accommodating the circlip; the outer peripheral wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com