Grinder grinding wheel protection cover

A protective cover, grinding wheel technology, applied in grinding/polishing equipment, grinding/polishing safety devices, metal processing equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

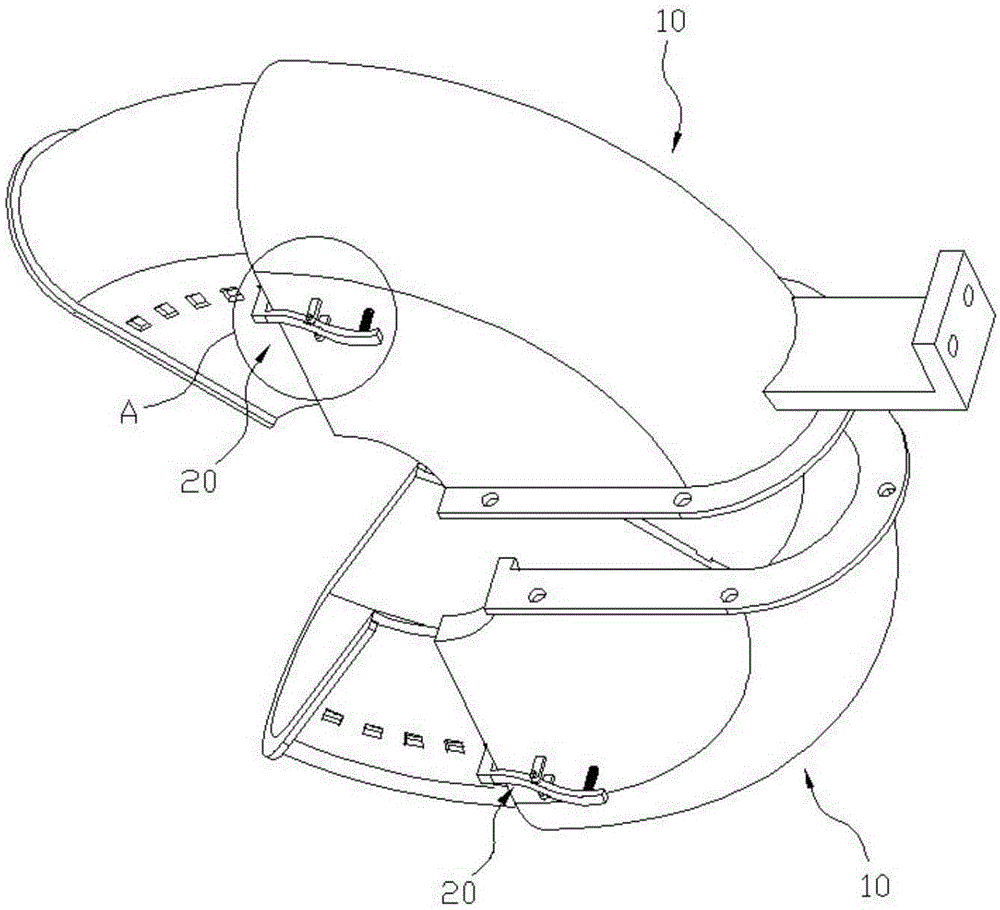

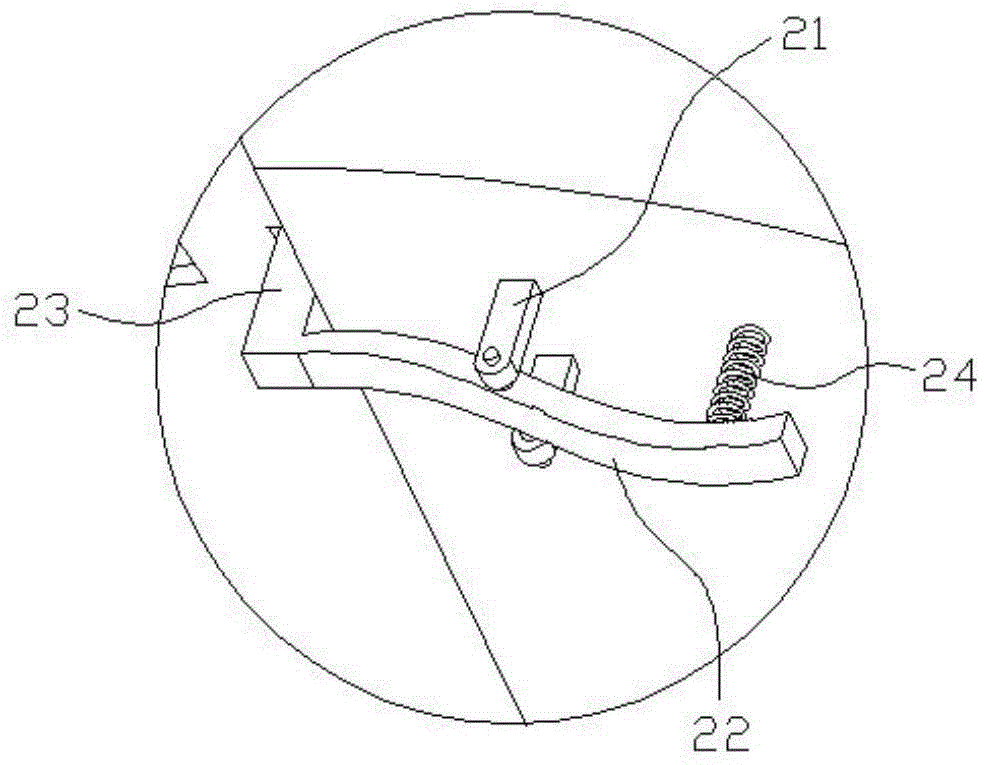

[0026] Such as figure 1 As shown, a grinding wheel guard for a grinding machine includes two casings 10 and a locking device 20 installed on the casings.

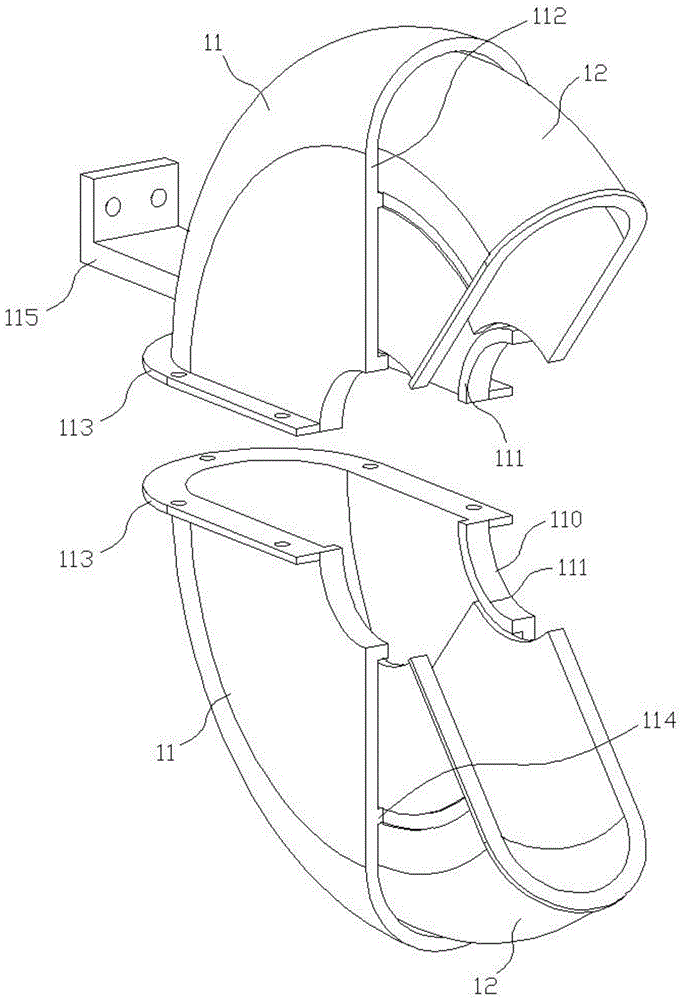

[0027] combine image 3 , Figure 4 , Figure 5 As shown, the housing 10 includes an outer shell 11 and an inner shell 12 .

[0028] combine image 3 , Figure 4 , Figure 5 As shown, the above-mentioned housing 11 is fan-shaped, the central angle of the fan-shaped housing 11 is 90 degrees, and the cross-section of the housing 11 is arched. The outer shell 11 includes a cavity for accommodating the inner shell 12 , and an arc-shaped edge 110 at a central corner of the outer shell 11 is provided with an arc-shaped flange 111 protruding toward the cavity. The straight edge of the housing 11 is provided with a connecting flange 113 . A guide block 114 is provided on the inner wall of the housing 11 . The outer surface of the outer shell 11 of one of the two shells 10 is provided with a connecting portion 115 connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com