Front pillar structure of vehicles and vehicle

A column and automobile technology, applied in the direction of upper structure, upper structure sub-assembly, vehicle parts, etc., can solve problems such as structural deformation of hinges and stoppers, deformation and locking of doors, failure to meet safety requirements, etc., to improve strength, The effect of high security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

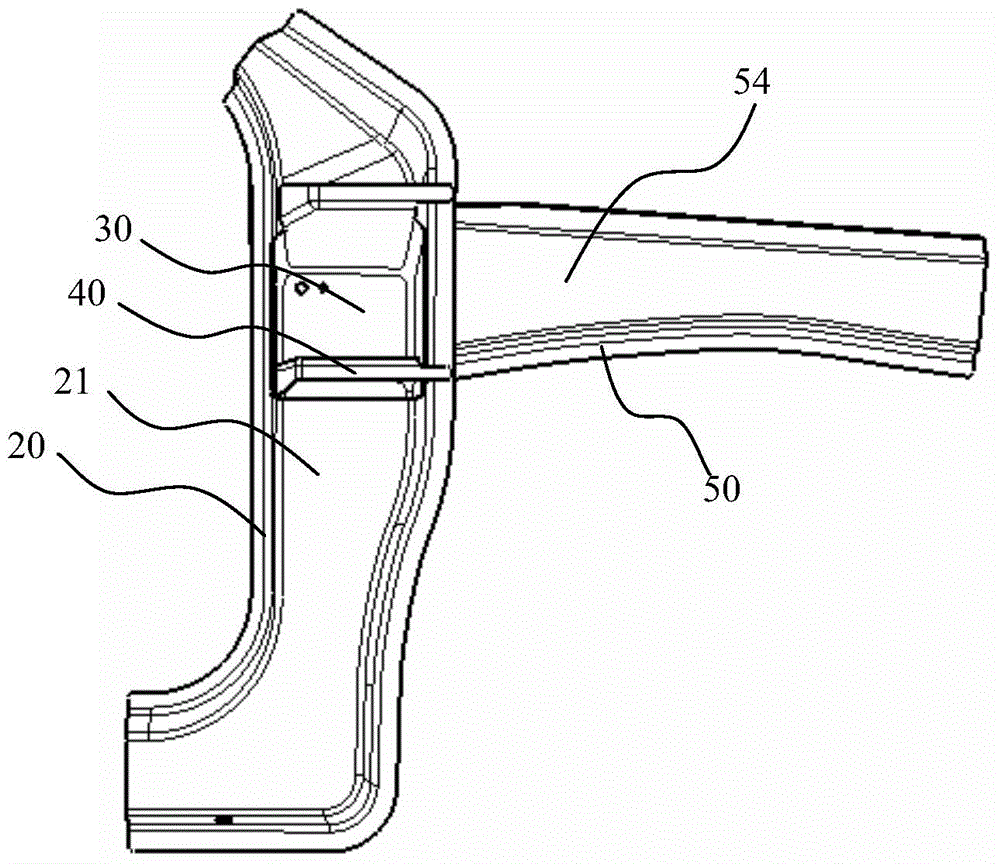

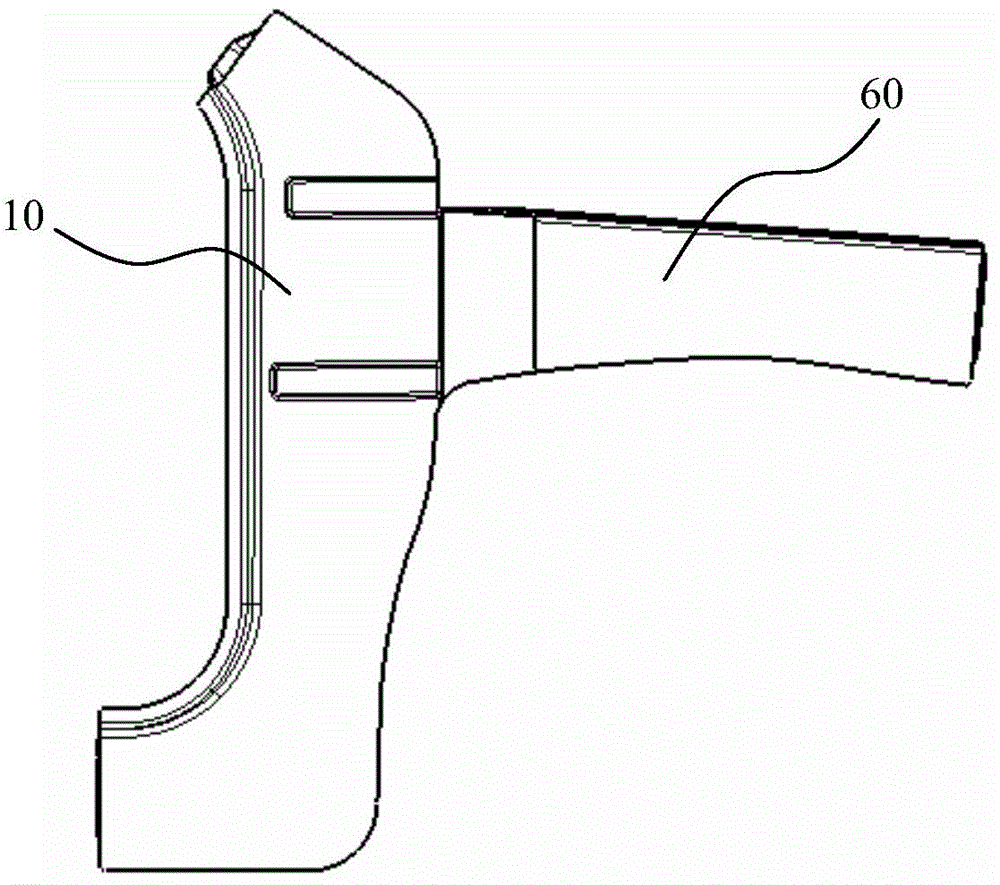

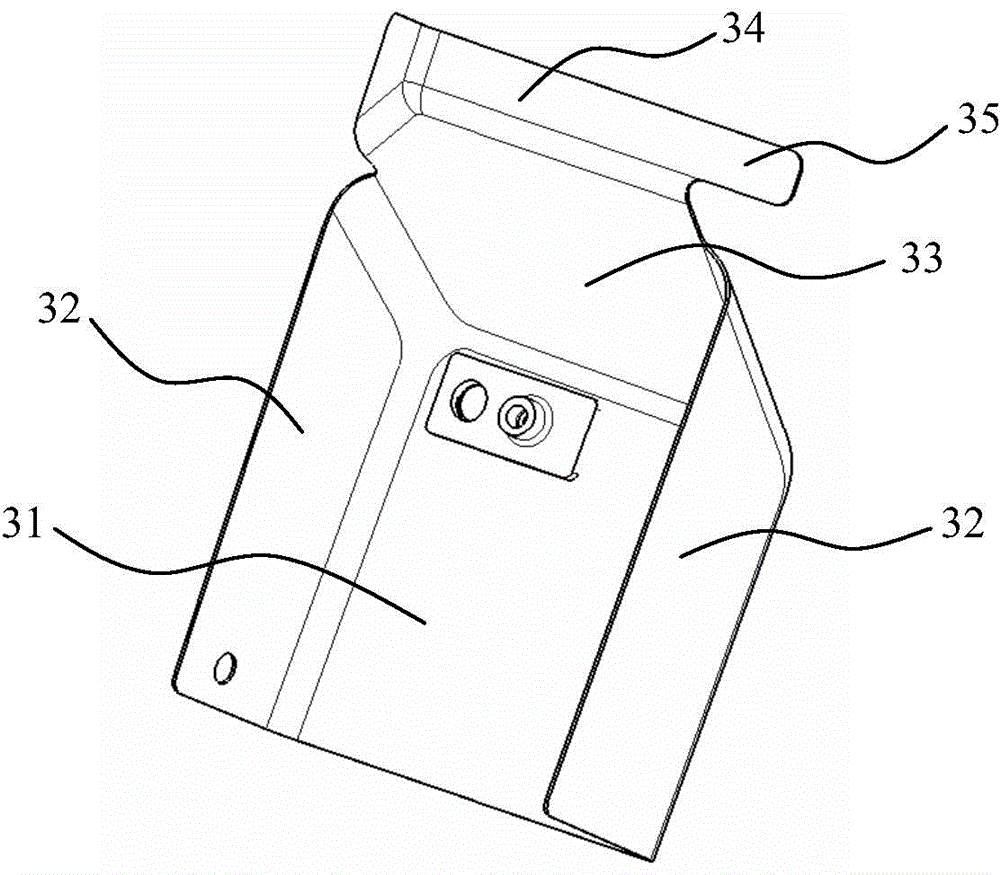

[0024] Such as figure 1 and figure 2 As shown, the front pillar structure of the automobile in this embodiment includes a front pillar mechanism, a part reinforcement mechanism and a roof side beam mechanism. The front pillar mechanism includes a front pillar inner panel 10 and a front pillar reinforcement plate 20 fixedly connected with the front pillar inner panel 10 , and the front pillar mechanism has a first cavity 21 . The part strengthening mechanism is fixed inside the first chamber 21 . The roof sill mechanism includes a roof sill outer panel 50 , which is fixedly connected to the front pillar mechanism, and is characterized in that the component reinforcement mechanism corresponds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com