Separation method of difluoroethanol-water azeotrope

A difluoroethanol, water azeotrope technology, applied in the chemical industry, can solve the problems of large pollution, impact on human health, only purity, etc., and achieve the effect of small pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

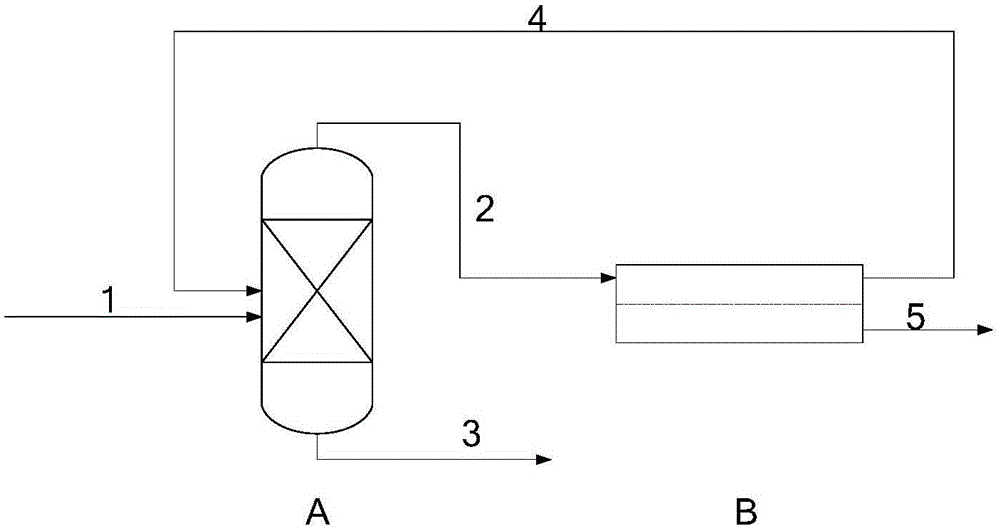

[0028] A mixture of 80% by mass of difluoroethanol and 20% by mass of water is fed from the middle of rectification tower A at a temperature of 80°C, and gas-liquid is carried out in rectification tower A under a pressure of 100kPa. Phase separation, reflux ratio 2, tower top temperature 92°C, azeotrope of difluoroethanol and water at the top of tower A; temperature of distillation tower A bottom is 95°C, tower bottom is difluoroethanol, purity 99.95%.

[0029] The temperature of the azeotrope of difluoroethanol and water drops to 60°C and enters the pervaporation device B. The feed liquid side is operated at a pressure of 100kPa. To rectification column A, the permeate is water with an organic content of 0.001%.

Embodiment 2

[0031] The mass percentage content of difluoroethanol is 75% and the mixture of water mass percentage content is 25%. The phases are separated, the reflux ratio is 3, the top temperature is 98°C, and the top of tower A is an azeotrope with water; the temperature of the distillation column A bottom is 101°C, and the bottom bottom is difluoroethanol with a purity of 99.92%.

[0032] The temperature of the azeotrope of difluoroethanol and water drops to 60°C and enters the pervaporation device B. The feed liquid side is operated at a pressure of 120kPa, the feed liquid measurement operating temperature is 60°C, and the pressure behind the membrane is 1kPa. In rectification column A, the permeate is water, and the organic matter content is 0.0015%.

Embodiment 3

[0034] Difluoroethanol mass percentage content is 80% and the mixture of water mass percentage content is 20% under the condition of temperature 95 ℃, feeds from the middle part of rectifying tower A, under the pressure of 200kPa, gas-liquid is carried out in rectifying tower A The phases are separated, the reflux ratio is 5, the top of tower A is an azeotrope of difluoroethanol and water, and the temperature at the top of the tower is 113°C; the temperature of the bottom of rectification tower A is 116°C, and the bottom of the tower is difluoroethanol, with a purity of 99.93%.

[0035] The temperature of the azeotrope of difluoroethanol and water drops to 60°C and enters the pervaporation device B. The feed liquid side is operated at a pressure of 200kPa. In rectification column A, the permeate is water, and the organic matter content is 0.0012%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com