Production technology of mdyb-3 aviation plexiglass products with complex curved surfaces

A MDYB-3, 1.MDYB-3 technology is applied in the production process of MDYB-3 aviation plexiglass complex curved products, which can solve the problem of inability to manufacture high-performance MDYB-3 aviation plexiglass complex curved products, etc. Avoid the effects of poor glass shape, high interchangeability, and avoidance of optical performance degradation

Active Publication Date: 2016-09-21

CHENGDU JUFENG GLASS LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a production process of MDYB-3 aviation plexiglass complex curved surface products, to solve the problem that the prior art cannot manufacture high-performance MDYB-3 aviation plexiglass complex curved surface products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

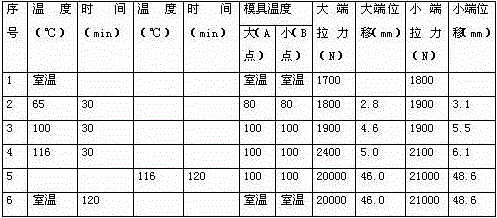

[0018] The production process of MDYB-3 aviation plexiglass wingtip navigation light shade, the specific process is as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a production technology of an MDYB-3 aviation organic glass complex curved surface product. The technology comprises the following steps: (1) aviation glass is cut, X-axis drilling is carried out on the glass, a clamping plate is assembled, the glass is placed on a mould in an oven and is preheated and heated, and therefore the aviation glass is softened; (2) the clamping plate is put down, the aviation glass naturally hands to be attached to the mould, after the surface temperature of the aviation glass is cooled to the indoor temperature, Y-axis drilling is carried out on the glass, the clamping plate is assembled, then, the oven is closed, and warming and forming pulling are carried out on the aviation glass; (3) after the aviation glass is completely attached to the mould, the aviation glass is cooled to the indoor temperature, and the appearance of the aviation glass is cut into the appearance of a semi-finished product; (4) edge shape correcting is carried out on the semi-finished product, and coarse edging and fine edging are carried out on the edge portion; (5) the surface of the edged aviation glass is ground, burnished, polished and cleaned, and the finished product is obtained. The product manufactured through the technology has the advantages of being good in appearance joint degree, high in interchangeability and good in optical performance.

Description

technical field [0001] The invention relates to a production process of MDYB-3 aviation plexiglass complex curved surface product. Background technique [0002] With the increasing demand for modern civil and military air transport, the need to develop a new type of transport aircraft with large carrying capacity is becoming increasingly urgent. MDYB-3 aviation plexiglass material, as a new type of aviation transparent material, has been widely used in military, civilian and other fields. MDYB-3 aerospace plexiglass complex curved surface products will change its internal molecular order during hot bending forming process, resulting in performance changes, and at the same time, there is a characteristic that the thickness change will cause optical performance to decrease. Therefore, the molding process of MDYB-3 aviation plexiglass is more complicated. . The traditional process is compression molding, which can only form ordinary plexiglass and non-directional stretch form...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B64C1/14B29C51/04B29C51/26B29C37/00

Inventor 刘钢邓玉梅陈运龙邱继海林宪张红

Owner CHENGDU JUFENG GLASS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com