Resonance device for large steel cylinder vibrating and sinking

A steel cylinder, large-scale technology, applied in the field of resonance devices for vibration and sinking of large steel cylinders, can solve the problems of destroying the foundation soil, more stringent requirements for shape and structural form, large steel cylinder structure size, etc. , to achieve the effect of improving the overall quality, meeting the requirements for the transmission of the axis of the exciting force, and the transmission of the axis of the excitation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

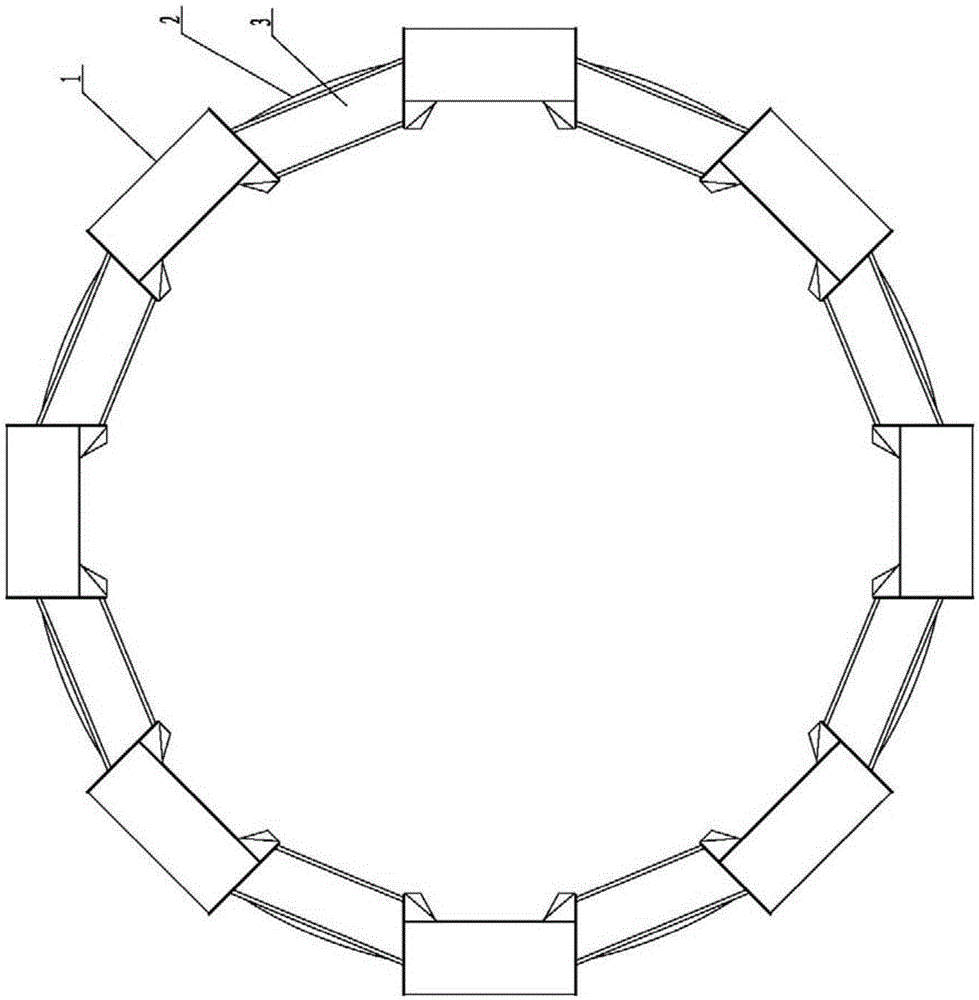

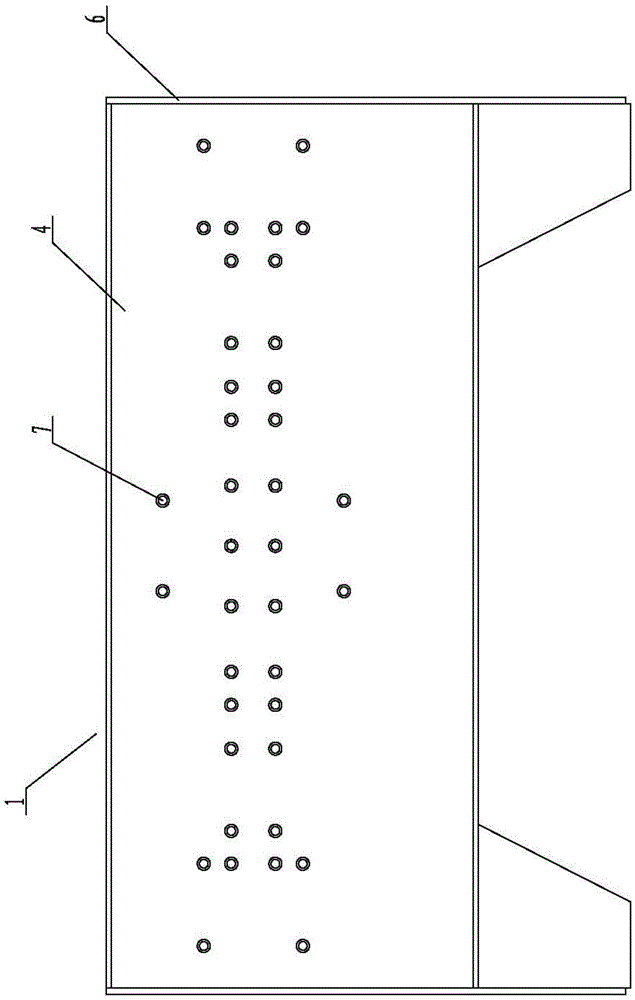

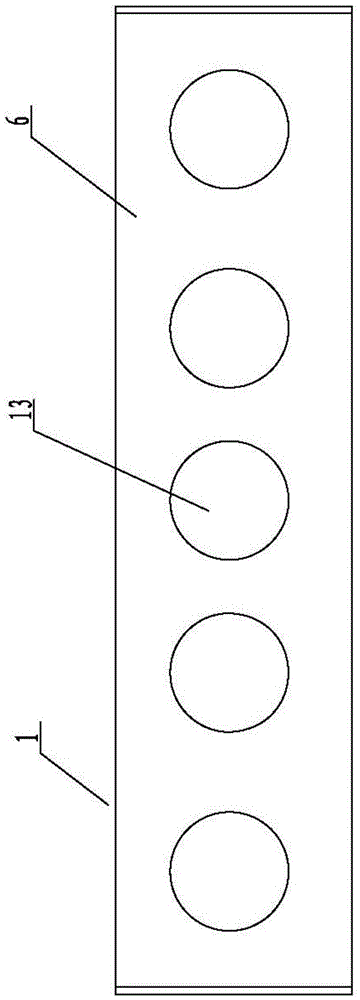

[0022] see figure 1 , figure 2 , image 3 , Figure 4 Shown, the large-scale steel cylinder of the present invention vibrates and sinks with resonance device, and this resonance device comprises a plurality of vibrating beams 1 that are used to transmit the exciting force of vibrating hammers and a plurality of vibrating beams 1 that are used to make each vibrating hammer exciting force on the steel cylinder Connecting beams 3 that are evenly distributed on the mouth of the cylinder and can be used as a synchronous linkage conduction platform; the vibration beams are vertically arranged on the mouth of the steel cylinder, and arranged in sequence at equal intervals along the circumferential direction of the mouth of the cylinder; the connecting beams are connected Between two adjacent vibrating beams. The present invention adopts the design of the vibrating beam and the connecting beam, and the exciting force is accurately transmitted to the large steel cylinder through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com