Manganese-doped titanium dioxide nanotube array film, gas sensor and preparation method thereof

A technology of nanotube array and titanium dioxide, which is applied in the direction of nanotechnology, analysis of gas mixture, gas analyzer structure details, etc., can solve the problems affecting the nano effect of materials, achieve large specific surface area, improve gas sensing performance, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

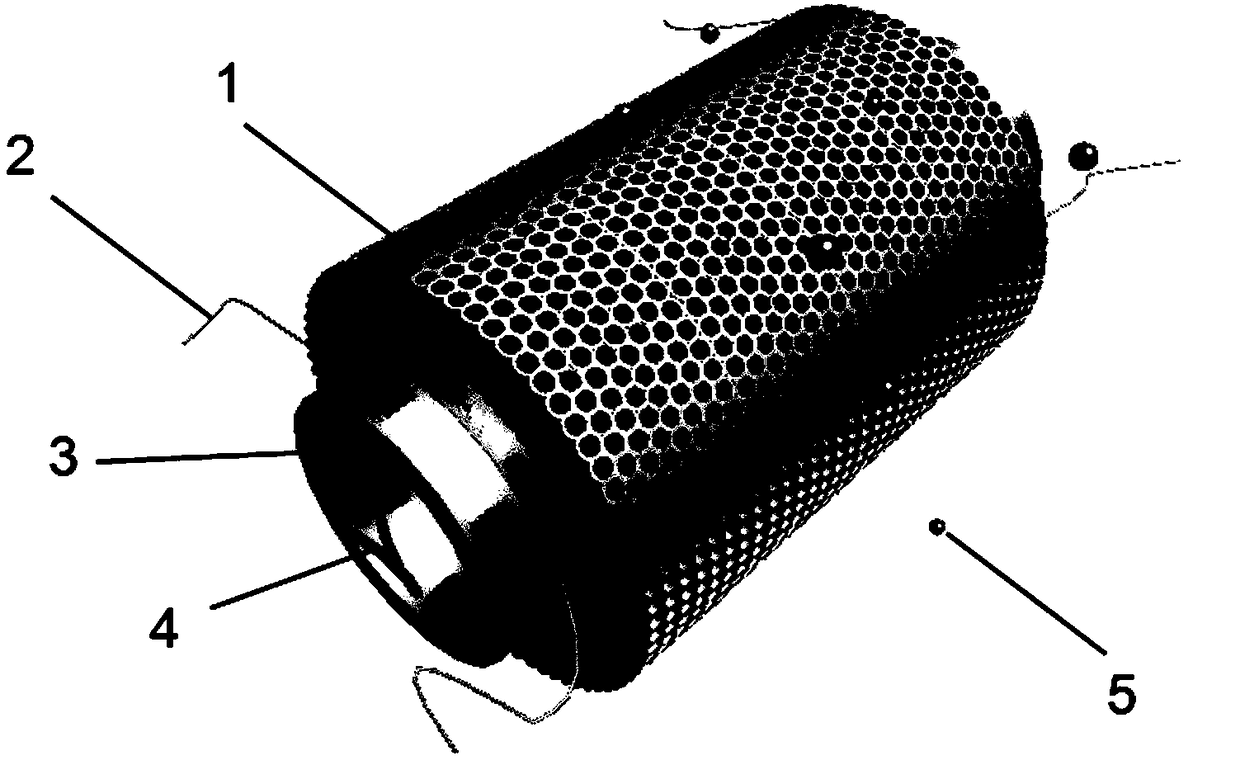

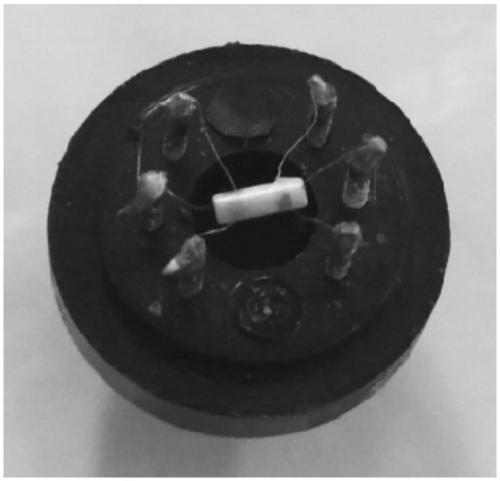

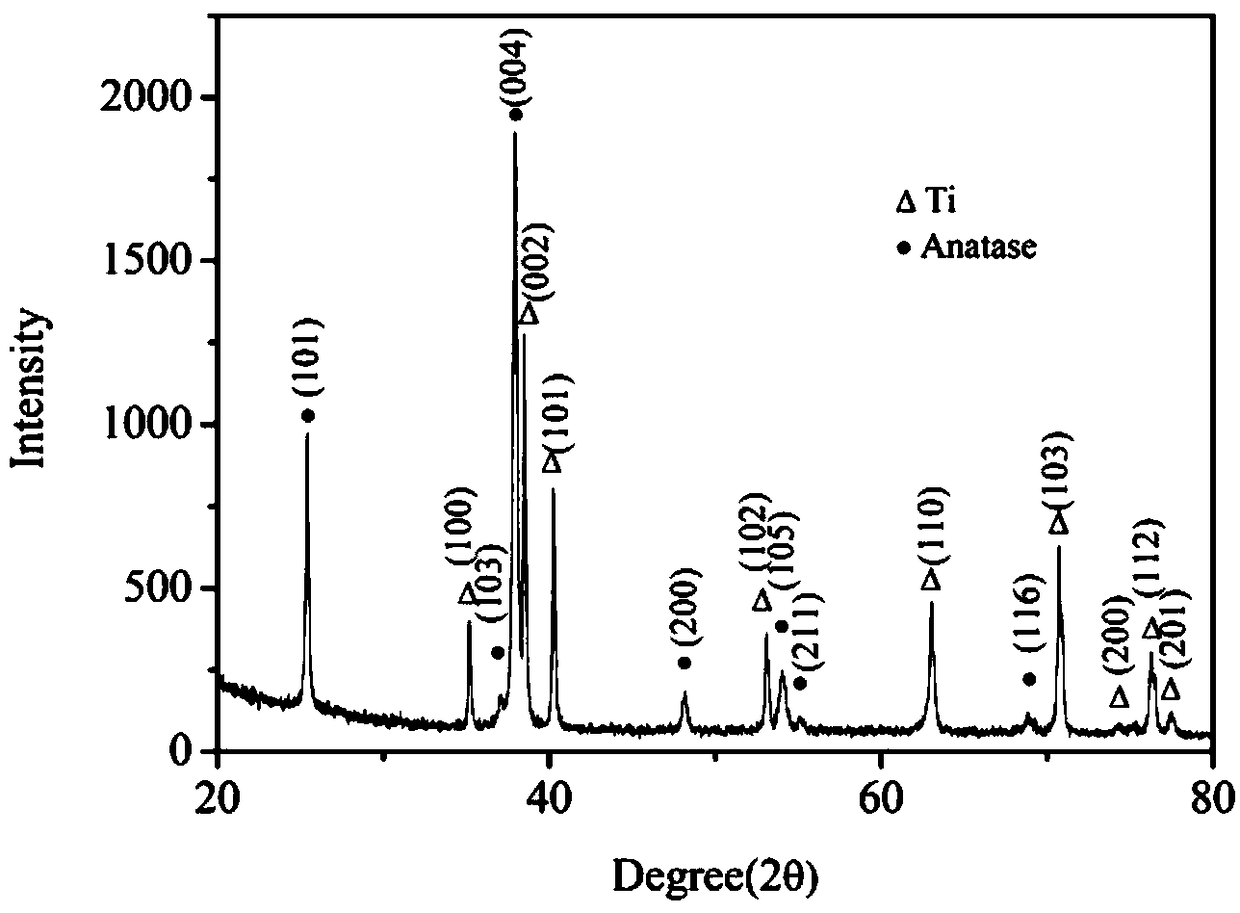

[0032] Use the polished titanium sheet as the anode, roll the titanium sheet into an arc shape, the convex surface of the titanium sheet is facing the cathode of the graphite sheet, and use ethylene glycol-NH 4 F-Mn(CH3 COO) 2 The system is used as an electrolyte, which contains 1.8wt% deionized water, 0.3wt% NH 4 F and 0.1g / L Mn(CH 3 COO) 2 , ethylene glycol is the remainder (the following examples are the same), and anodic oxidation is carried out at a voltage of 30V for 1h. Immerse the oxidized titanium sheet in 30% hydrogen peroxide for 10 minutes, take it out and immerse it in deionized water for 10 minutes to ultrasonically remove the oxide film formed on the surface of the titanium sheet, and then put it into the same electrolyte as above for a second anodic oxidation reaction for 3 hours. The reacted titanium sheet was cleaned with ethanol, dried in an oven at 80°C, and then heat-treated in a muffle furnace at 450°C for 3 hours. Put the heat-treated titanium sheet ...

Embodiment 2

[0035] Referring to Example 1, the difference is that the electrolyte contains 5.4wt% deionized water, 0.5wt% NH 4 F and 0.5g / L Mn(CH 3 COO) 2 . The material was prepared by anodizing at 20V for 1.5h, and the second anodizing reaction was 6h (20V). After cleaning, dry it in an oven at 110°C, and then heat-treat it at 350°C for 4 hours. Three times anodic oxidation reaction 12h (20V). According to the method of Example 1, a nanotube array membrane ceramic tube element was fabricated, dried at 110° C., and heat treated at 350° C. for 4 hours to obtain a manganese-doped titanium dioxide nanotube array membrane gas sensor.

Embodiment 3

[0037] Referring to Example 1, the difference is that the electrolyte contains 3.6wt% deionized water, 0.2wt% NH 4 F and 0.2g / L of Mn(CH 3 COO) 2 . The material was prepared by anodizing at 40V for 0.5h, followed by secondary anodizing for 1h (40V). After cleaning, put it into a 90°C oven for drying, and then heat-treat it at 550°C for 4 hours. Three times anodic oxidation reaction 15h (40V). According to the method of Example 1, a nanotube array membrane ceramic tube element was fabricated, dried at 90° C., and heat treated at 550° C. for 4 hours to obtain a manganese-doped titanium dioxide nanotube array membrane gas sensor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com